α-Lipoic Acid Polymerization: Causes and Solutions

-

Table of Contents

α-Lipoic Acid Polymerization: Causes and Solutions

α-Lipoic acid (ALA) is a naturally occurring compound that plays a pivotal role in mitochondrial bioenergetic processes. Widely recognized for its antioxidant properties, ALA is not only crucial in aerobic metabolism but is also extensively used in supplements for its potential health benefits. However, the polymerization of α-lipoic acid can pose significant challenges in pharmaceutical and nutritional applications, affecting both its efficacy and stability. This article explores the causes of α-lipoic acid polymerization and proposes practical solutions to mitigate this issue.

Understanding α-Lipoic Acid Polymerization

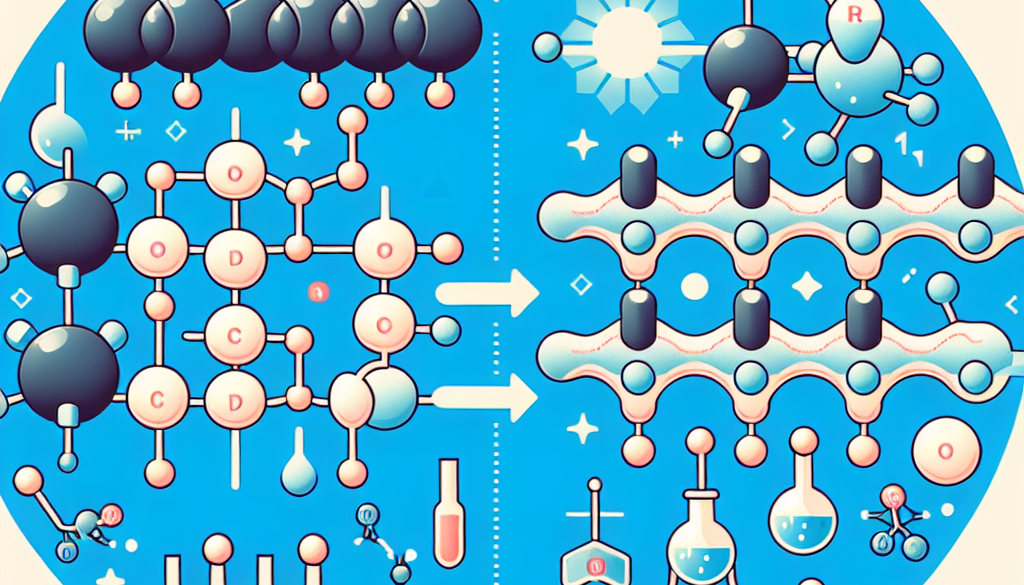

α-Lipoic acid polymerization refers to the process where individual ALA molecules bond together, forming larger molecular structures. This transformation can alter the chemical properties of ALA, leading to decreased bioavailability and effectiveness. Polymerization is influenced by various factors, including environmental conditions and chemical interactions.

Causes of α-Lipoic Acid Polymerization

- Temperature: High temperatures can accelerate the polymerization process of ALA. Heat provides the energy necessary for ALA molecules to overcome activation barriers, leading to increased bonding.

- pH Levels: The acidity or alkalinity of the solution can also affect polymerization rates. Extreme pH levels can promote ionic states that facilitate the bonding of ALA molecules.

- Presence of Catalysts: Certain substances can act as catalysts, speeding up the polymerization process. Metals such as iron and copper are particularly effective in catalyzing this reaction.

- Oxidative Conditions: Oxidative environments contribute to the polymerization of ALA. Oxidative stress can create free radicals, which can initiate and propagate chain reactions leading to polymerization.

Solutions to Prevent α-Lipoic Acid Polymerization

To maintain the stability and effectiveness of α-lipoic acid in various applications, it is crucial to address the factors that contribute to its polymerization. Here are several strategies to prevent or minimize this process:

- Temperature Control: Storing α-lipoic acid at lower temperatures can significantly reduce the rate of polymerization. Cold storage conditions help maintain the integrity of ALA by slowing down molecular motion.

- pH Optimization: Maintaining the pH of ALA solutions within a moderate range can prevent extreme conditions that favor polymerization. Buffer solutions can be used to stabilize pH levels.

- Use of Antioxidants: Adding antioxidants to ALA formulations can help scavenge free radicals, thereby reducing oxidative conditions that lead to polymerization.

- Chelating Agents: Incorporating chelating agents that bind to metal ions can inhibit the catalytic effects of metals on ALA polymerization.

- Formulation Adjustments: Modifying the formulation of ALA-containing products to include stabilizers or protective coatings can shield ALA molecules from environmental factors that promote polymerization.

Implementing Solutions in Industry

The practical application of these solutions can vary based on the specific requirements of different industries. For instance, in pharmaceuticals, where precision and stability are paramount, advanced techniques such as encapsulation and cryopreservation might be employed. In nutritional supplements, simpler methods like antioxidant addition and careful control of storage conditions can be effective.

Conclusion

α-Lipoic acid polymerization is a significant concern in its application across various industries due to its impact on the compound’s stability and effectiveness. Understanding the causes of polymerization and implementing effective solutions is crucial for maintaining the quality and therapeutic benefits of ALA. By controlling environmental factors such as temperature and pH, and by incorporating chemical strategies such as antioxidants and chelating agents, the stability of α-lipoic acid can be significantly enhanced.

Explore ETprotein’s High-Quality Protein Products

If you are looking for high-quality protein formulations, consider exploring the offerings from ETprotein. Their extensive range of organic and allergen-free protein products is ideal for various applications, including nutritional supplements and food additives. ETprotein’s commitment to quality and customer satisfaction makes them a top choice for your protein needs.

ETprotein is α-lipoic acid Factory Manufacturer and Supplier in China, Check further information by visiting the α-lipoic acid Product Page

Request Quotation and Samples of α-lipoic acid from ETprotein

About ETprotein

ETprotein, a reputable protein and elite nutrition ingredients α-lipoic acid Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and elite nutritional ingredients α-lipoic acid. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.