A Comprehensive Overview of Canned Food Safety Testing

-

Table of Contents

- Canned Food Safety Testing: Ensuring Quality and Health Standards

- Understanding Canned Food Safety

- The Canning Process

- Potential Hazards in Canned Foods

- Key Aspects of Canned Food Safety Testing

- Microbiological Testing

- Chemical Testing

- Physical Testing

- Regulatory Framework and Standards

- Compliance with Regulations

- International Standards

- Advancements in Safety Testing Technologies

- Innovative Testing Methods

- Automation in Testing

- Consumer Awareness and Best Practices

- Storage and Handling Guidelines

- Education on Food Safety

- Conclusion: The Importance of Canned Food Safety Testing

- ETprotein: Your Trusted Source for High-Quality Protein Products

Canned Food Safety Testing: Ensuring Quality and Health Standards

The safety of canned foods is a critical concern for consumers, manufacturers, and health authorities worldwide. With the convenience and long shelf life of canned goods, ensuring that these products are free from contaminants and safe for consumption is paramount. This comprehensive overview will delve into the various aspects of canned food safety testing, highlighting the importance of rigorous testing protocols and the role they play in maintaining public health.

Understanding Canned Food Safety

Canned foods are a staple in many households due to their convenience and extended shelf life. However, the canning process and the storage of these foods present unique safety challenges that must be addressed through stringent safety testing.

The Canning Process

The canning process involves sealing food in airtight containers and then heating it to a temperature that destroys microorganisms that can cause spoilage or illness. While this process is effective in preserving food, it also creates an environment where certain bacteria, such as Clostridium botulinum, can thrive if the food is not processed correctly.

Potential Hazards in Canned Foods

- Microbial Contamination: Bacteria, viruses, and parasites can survive in improperly canned foods, leading to foodborne illnesses.

- Chemical Contamination: The presence of heavy metals, bisphenol A (BPA), and other chemicals can leach from the can’s lining into the food.

- Physical Contamination: Foreign objects such as glass or metal can sometimes be found in canned goods due to processing errors.

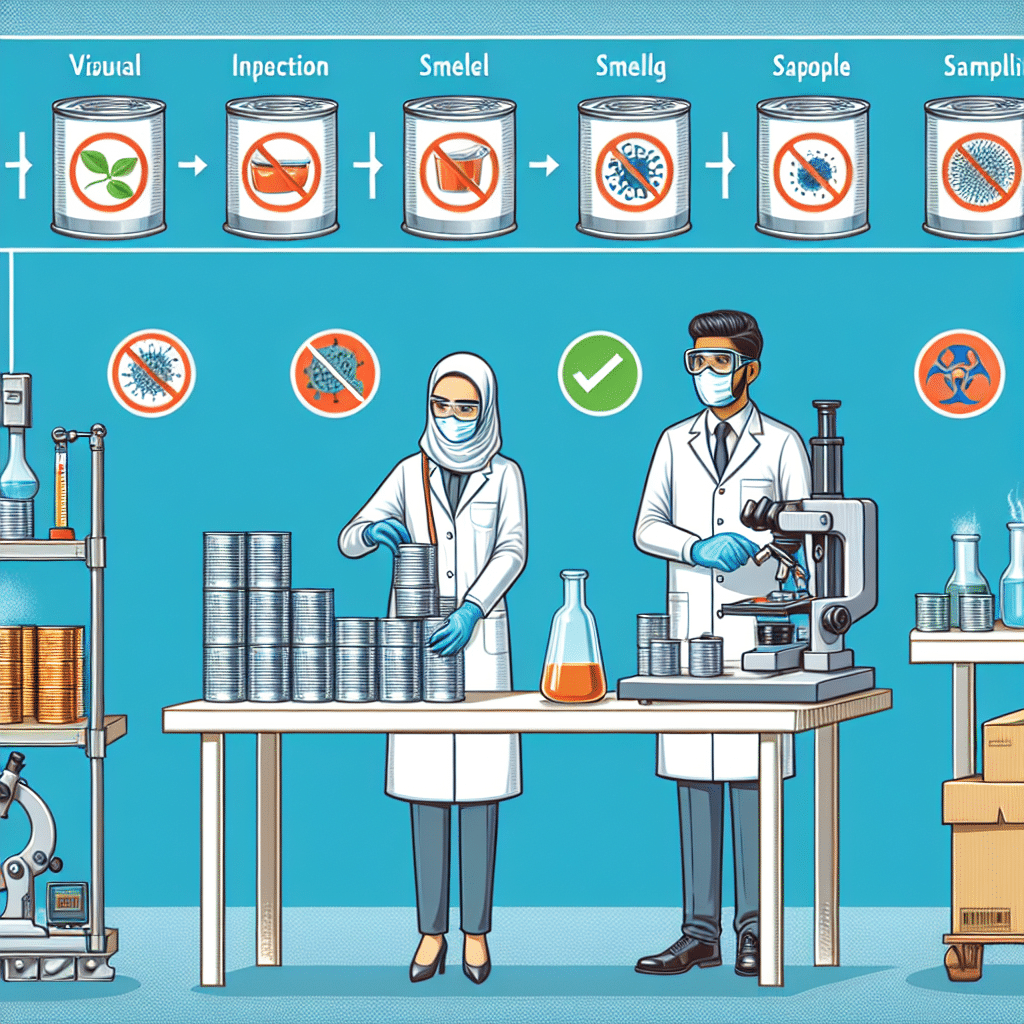

Key Aspects of Canned Food Safety Testing

Canned food safety testing encompasses a range of procedures designed to detect and prevent potential hazards. These tests are crucial for ensuring that canned foods are safe for consumption.

Microbiological Testing

Testing for harmful microorganisms is a critical component of food safety. This includes screening for pathogens like Salmonella, Listeria monocytogenes, and E. coli, as well as spoilage organisms that can affect the food’s quality and safety.

Chemical Testing

Chemical analyses are performed to detect the presence of contaminants such as heavy metals, pesticides, and industrial chemicals. Additionally, testing for migration of substances from the can’s material into the food is conducted to ensure compliance with safety standards.

Physical Testing

Physical inspections are carried out to identify any foreign objects in the canned goods. This also includes ensuring that the cans are properly sealed and free from defects that could compromise the food’s safety.

Regulatory Framework and Standards

Globally, various regulatory bodies set standards and guidelines for canned food safety. These organizations include the Food and Drug Administration (FDA) in the United States, the European Food Safety Authority (EFSA) in the European Union, and others.

Compliance with Regulations

Manufacturers must adhere to the regulations set by these authorities, which dictate acceptable levels of contaminants, processing requirements, and labeling standards.

International Standards

International standards such as those from the Codex Alimentarius Commission provide a benchmark for food safety practices and facilitate international trade by harmonizing regulations across different countries.

Advancements in Safety Testing Technologies

Technological advancements have significantly improved the efficiency and accuracy of canned food safety testing. Rapid testing methods and sophisticated analytical instruments now allow for quicker detection of contaminants and pathogens.

Innovative Testing Methods

New molecular techniques, such as polymerase chain reaction (PCR) and next-generation sequencing (NGS), offer precise identification of microorganisms. Additionally, advanced chromatography and spectrometry techniques provide detailed chemical analyses.

Automation in Testing

Automation has streamlined the testing process, reducing human error and increasing the throughput of samples that can be analyzed, thereby enhancing overall safety monitoring.

Consumer Awareness and Best Practices

Consumers play a vital role in maintaining the safety of canned foods. Understanding best practices for storage and handling can prevent foodborne illnesses.

Storage and Handling Guidelines

Proper storage conditions and adherence to expiration dates are essential. Consumers should also inspect cans for any signs of damage or swelling before use.

Education on Food Safety

Educational initiatives by health authorities and consumer groups help raise awareness about the importance of food safety and the steps individuals can take to protect themselves and their families.

Conclusion: The Importance of Canned Food Safety Testing

Canned food safety testing is a critical component of the global food supply chain. Through rigorous testing protocols, adherence to regulatory standards, and advancements in technology, the industry strives to ensure that canned foods remain safe and of high quality. Consumers also play a crucial role by following best practices for storage and handling. Together, these efforts contribute to the prevention of foodborne illnesses and the protection of public health.

ETprotein: Your Trusted Source for High-Quality Protein Products

In addition to understanding the importance of food safety in canned goods, it’s essential to recognize the value of incorporating high-quality protein into your diet. ETprotein offers a range of organic bulk vegan proteins and L-(+)-Ergothioneine (EGT) products that meet the highest standards of purity and quality. Whether you’re a manufacturer, distributor, or consumer, ETprotein’s products are an excellent choice for those seeking reliable and nutritious protein options.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.