Adoption Of Automation In The Food and Beverage Industry

-

Table of Contents

- Automation Adoption in the Food and Beverage Industry: A Deep Dive

- The Rise of Automation in Food and Beverage Manufacturing

- Benefits of Automation in the Food and Beverage Sector

- Challenges and Considerations

- Statistics Supporting Automation Growth

- Case Studies: Success Stories of Automation

- The Future of Automation in the Food and Beverage Industry

- Conclusion: Embracing Automation for a Competitive Edge

- ETprotein: Enhancing Food and Beverage Products with Quality Proteins

Automation Adoption in the Food and Beverage Industry: A Deep Dive

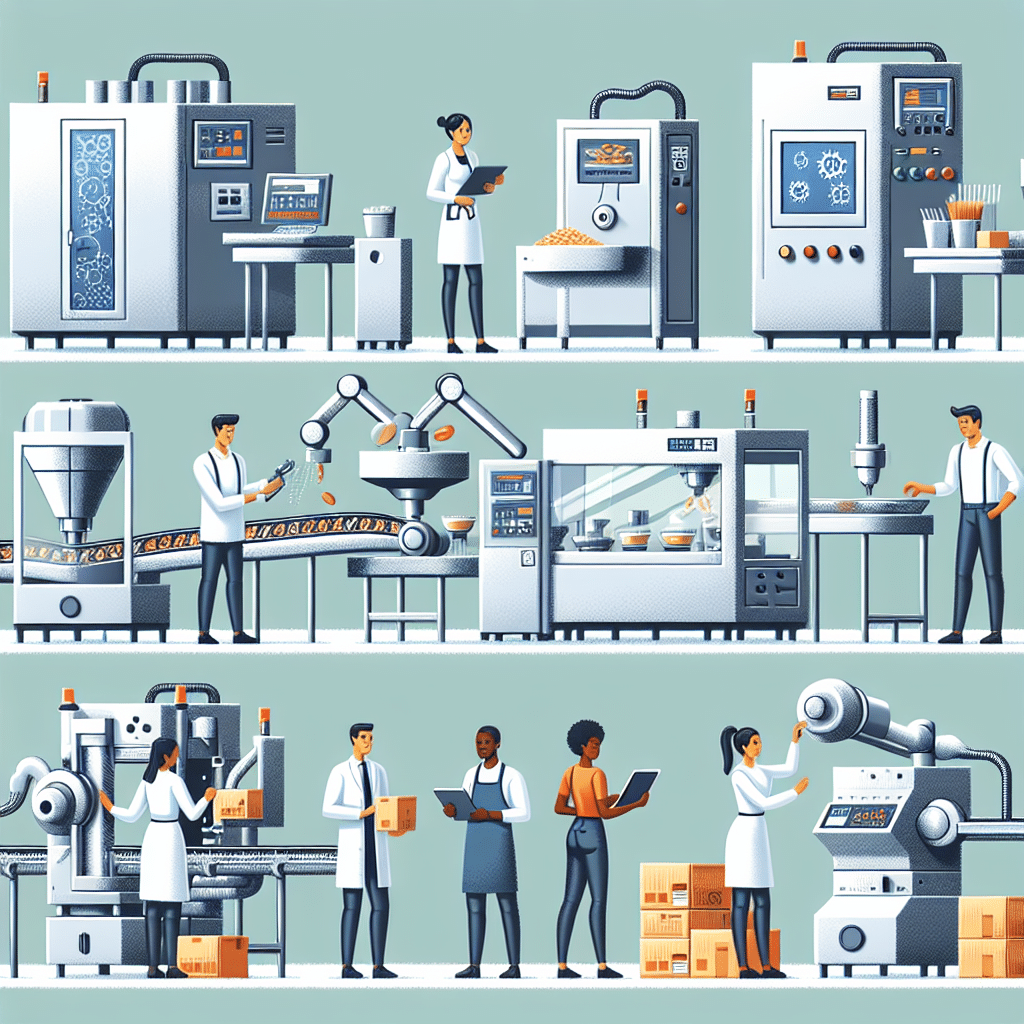

The food and beverage industry is undergoing a significant transformation, driven by the relentless pursuit of efficiency, consistency, and safety. Automation has emerged as a key player in this revolution, offering solutions that streamline operations, reduce costs, and enhance product quality. This article explores the adoption of automation in the food and beverage sector, highlighting its benefits, challenges, and future prospects.

The Rise of Automation in Food and Beverage Manufacturing

Automation in the food and beverage industry is not a new concept; however, its adoption has accelerated in recent years. Technological advancements have made automation more accessible and cost-effective, leading to its widespread implementation across various stages of production, from processing and packaging to distribution.

- Processing: Automated systems are used for sorting, cutting, cooking, and other processing tasks.

- Packaging: Robotics and conveyor systems streamline the packaging process, increasing speed and precision.

- Distribution: Automated storage and retrieval systems (AS/RS) and autonomous vehicles optimize warehouse operations and logistics.

Benefits of Automation in the Food and Beverage Sector

The adoption of automation brings a multitude of benefits to the food and beverage industry, including:

- Increased Efficiency: Automated systems can operate continuously, reducing downtime and increasing output.

- Consistency and Quality Control: Machines provide uniformity in production, ensuring consistent product quality.

- Enhanced Safety: Automation reduces the need for human intervention, minimizing the risk of contamination and workplace accidents.

- Labor Cost Reduction: Although there’s an initial investment, automation can lead to long-term savings on labor costs.

- Scalability: Automated systems can be scaled up or down to meet changing production demands.

Challenges and Considerations

Despite its advantages, the adoption of automation in the food and beverage industry is not without challenges:

- High Initial Investment: The cost of implementing automated systems can be prohibitive for some businesses.

- Technical Complexity: Operating and maintaining sophisticated machinery requires skilled personnel.

- Integration with Existing Systems: Integrating new technologies with legacy systems can be complex and time-consuming.

- Regulatory Compliance: Automated systems must comply with food safety and quality regulations, which can vary by region.

Statistics Supporting Automation Growth

Recent statistics underscore the growing adoption of automation in the food and beverage industry:

- A report by Meticulous Research states that the food automation market is expected to grow at a CAGR of 9.5% from 2020 to 2027.

- According to the Association for Packaging and Processing Technologies (PMMI), 94% of food manufacturers are using or considering automation.

Case Studies: Success Stories of Automation

Several food and beverage companies have successfully integrated automation into their operations:

- A leading dairy company implemented robotic palletizing systems, resulting in a 60% increase in palletizing speed.

- A brewery adopted automated brewing systems, which improved consistency and allowed for real-time monitoring of the brewing process.

The Future of Automation in the Food and Beverage Industry

The future of automation in the food and beverage industry looks promising, with ongoing advancements in artificial intelligence (AI), machine learning, and robotics. These technologies will further enhance the capabilities of automated systems, leading to smarter, more adaptive, and more efficient production processes.

Conclusion: Embracing Automation for a Competitive Edge

The adoption of automation in the food and beverage industry is no longer a matter of if but when. Companies that embrace these technologies can expect to see significant improvements in efficiency, product quality, and safety. While challenges exist, the benefits of automation make it a compelling investment for the future of food and beverage manufacturing.

ETprotein: Enhancing Food and Beverage Products with Quality Proteins

In line with the advancements in automation, ETprotein company’s protein products stand out as a valuable addition to the food and beverage industry. Their range of organic bulk vegan proteins and L-(+)-Ergothioneine (EGT) can be seamlessly integrated into automated production lines, ensuring that the end products are not only efficient to produce but also of the highest quality and nutritional value.

ETprotein’s commitment to non-GMO, allergen-free, and high-purity ingredients aligns with the industry’s move towards healthier and more sustainable food options. Their expertise in providing tailored protein solutions makes them an ideal partner for businesses looking to innovate and stay ahead in a competitive market.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.