Advantages Of Automating Bakery Processing Lines

-

Table of Contents

- Maximizing Efficiency: Advantages of Automating Bakery Processing Lines

- Consistency and Quality Control

- Increased Production Capacity

- Enhanced Efficiency and Reduced Waste

- Labor Cost Savings

- Improved Worker Safety

- Flexibility and Scalability

- Data Collection and Analysis

- Conclusion

- Enhance Your Bakery Products with ETprotein’s Premium Proteins

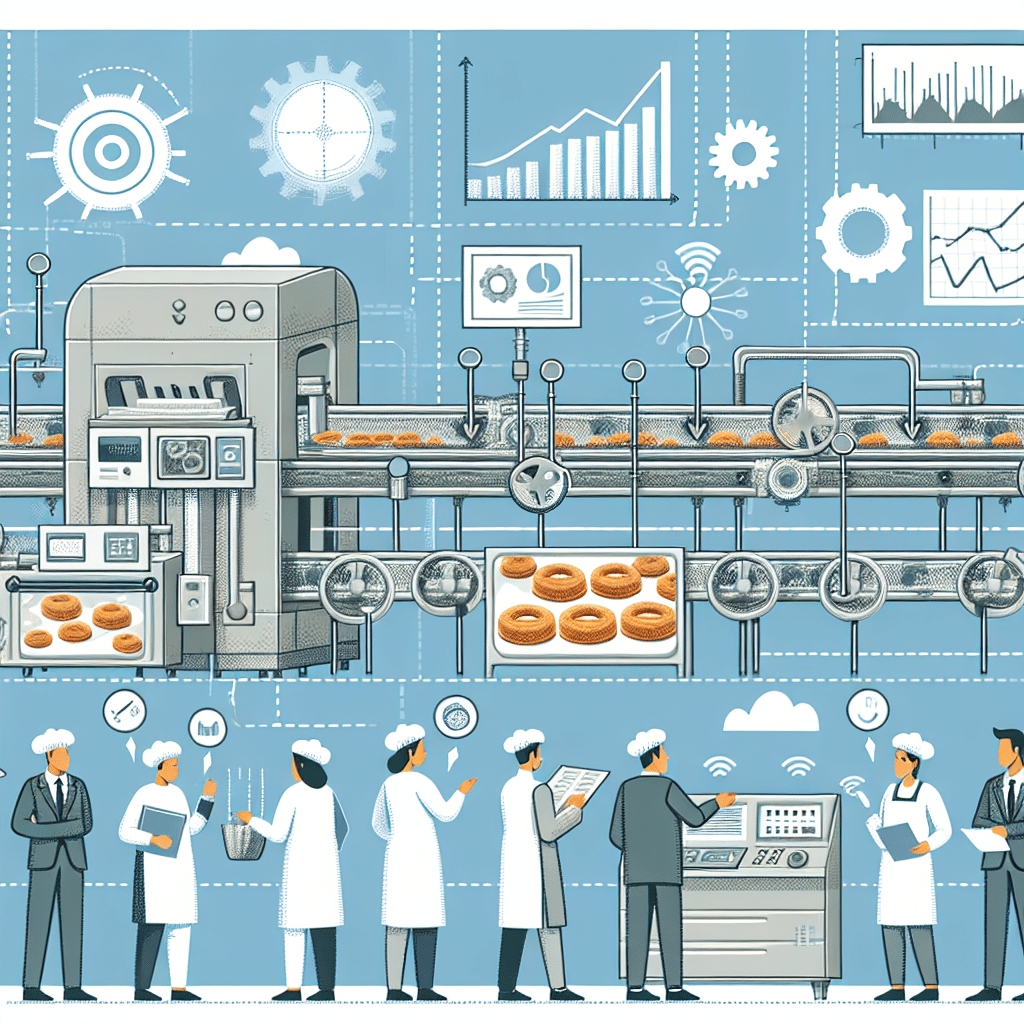

Maximizing Efficiency: Advantages of Automating Bakery Processing Lines

The bakery industry has seen a significant transformation over the years, with automation playing a pivotal role in enhancing production efficiency and product quality. Automating bakery processing lines is not just a trend; it’s a strategic move that can yield substantial benefits for bakery businesses of all sizes. In this article, we will explore the numerous advantages of integrating automation into bakery processing lines, supported by statistics and insights that underscore the value of this technological advancement.

Consistency and Quality Control

One of the most significant benefits of automation is the ability to produce consistent and high-quality baked goods. Automated systems are designed to follow precise recipes and processing parameters, ensuring that each product is identical in size, shape, and quality. This level of consistency is difficult to achieve with manual processes, where human error can lead to variations in the final product.

- Reduction in human error ensures uniformity in product weight, texture, and appearance.

- Automated quality control systems can detect and remove defective products, maintaining high standards.

Increased Production Capacity

Automation allows bakeries to significantly increase their production capacity without compromising on quality. Automated lines can operate at a constant speed, often 24/7, without the need for breaks or shift changes. This continuous operation can lead to a substantial increase in output.

- Statistics show that automation can increase production speeds by up to 75%.

- Automated lines can be scaled up to meet growing demand without additional labor costs.

Enhanced Efficiency and Reduced Waste

Efficiency is another area where automation shines. Automated bakery lines are optimized for minimal waste, ensuring that raw materials are used effectively. This not only reduces the cost of ingredients but also minimizes the environmental impact of production.

- Precise ingredient handling and dosing reduce overuse and waste of raw materials.

- Automated systems can quickly adjust to changes in production, reducing downtime and material loss.

Labor Cost Savings

While the initial investment in automation may be significant, the long-term labor cost savings can be substantial. Automated lines require fewer workers to operate, which can lead to savings on wages, training, and employee benefits.

- Automation can reduce the need for skilled labor, which is often in short supply and high demand.

- Reduced reliance on manual labor can lead to lower turnover rates and associated hiring costs.

Improved Worker Safety

Automating bakery processing lines also enhances worker safety by reducing the need for employees to engage in repetitive or potentially hazardous tasks. This can lead to a decrease in workplace injuries and associated costs.

- Automation reduces the risk of injuries from repetitive motion or heavy lifting.

- Automated equipment can handle high-temperature baking processes, reducing the risk of burns.

Flexibility and Scalability

Modern automated bakery lines are designed with flexibility in mind. They can be easily reconfigured to produce different products or accommodate changes in production volume, allowing bakeries to adapt to market trends and consumer demands.

- Modular automation systems can be expanded or modified as business needs change.

- Quick changeover capabilities allow for a diverse product range without extensive downtime.

Data Collection and Analysis

Automation systems are equipped with advanced data collection capabilities, providing valuable insights into production processes. This data can be used to optimize operations, reduce costs, and improve product quality.

- Real-time monitoring allows for immediate adjustments to improve efficiency and reduce waste.

- Historical data analysis can identify trends and inform strategic decision-making.

Conclusion

In conclusion, automating bakery processing lines offers a multitude of advantages, including improved consistency and quality control, increased production capacity, enhanced efficiency, reduced waste, labor cost savings, improved worker safety, flexibility, scalability, and valuable data collection. By embracing automation, bakeries can position themselves for success in a competitive market, ensuring they can meet the demands of modern consumers while maintaining profitability and sustainability.

Enhance Your Bakery Products with ETprotein’s Premium Proteins

If you’re looking to elevate your bakery products, consider incorporating ETprotein’s high-quality protein products. Their extensive range of organic bulk vegan proteins, including rice, pea, and various seed proteins, can enhance the nutritional profile of your baked goods. With a neutral taste and non-GMO, allergen-free attributes, ETprotein’s offerings are an excellent choice for bakeries aiming to cater to health-conscious consumers. To learn more about how ETprotein can support your bakery business, contact them at sales(at)ETprotein.com.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.