Advantages of Automation in the Food and Beverage Industry

-

Table of Contents

- Maximizing Efficiency: The Advantages of Automation in the Food and Beverage Industry

- Enhanced Productivity and Efficiency

- Consistency and Quality Control

- Cost Savings and Return on Investment

- Improved Worker Safety

- Flexibility and Scalability

- Environmental Sustainability

- Conclusion: Embracing the Future of Food and Beverage Production

- Discover ETprotein’s High-Quality Protein Products

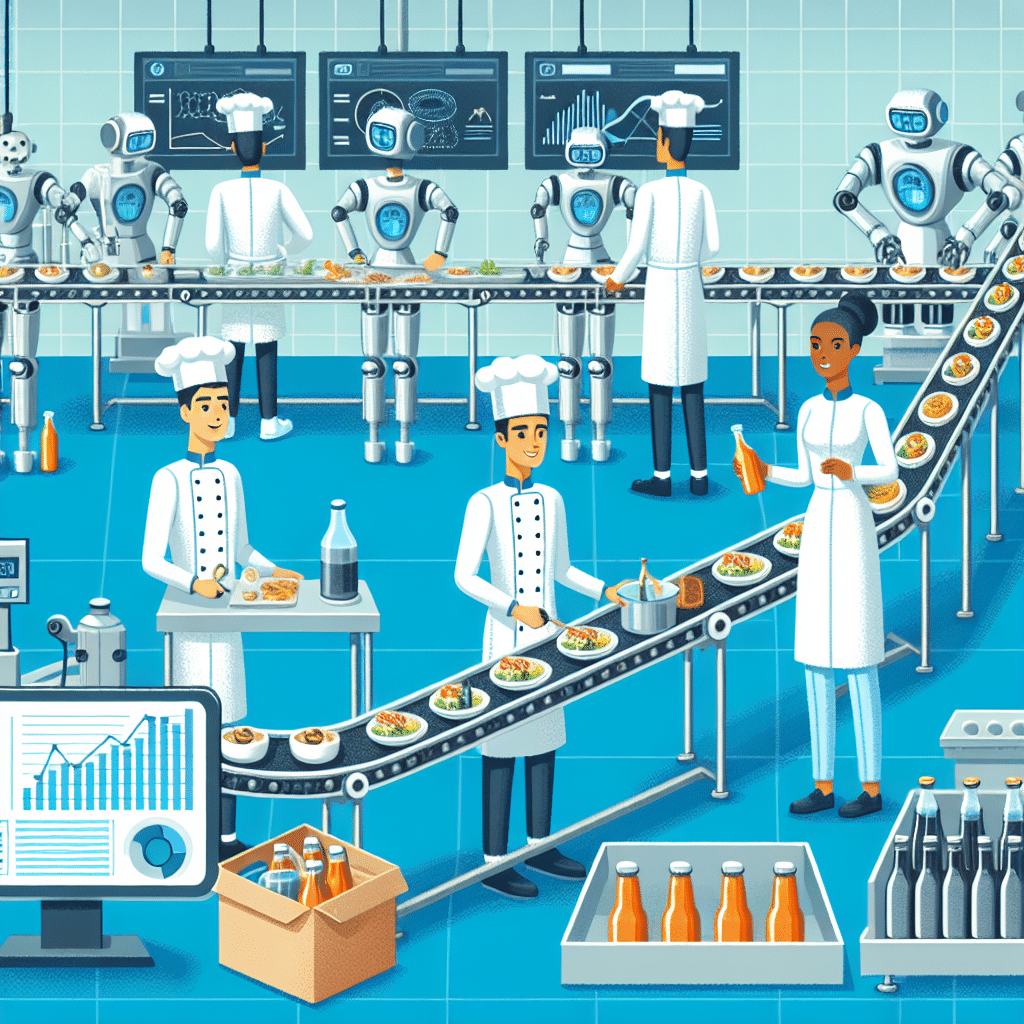

Maximizing Efficiency: The Advantages of Automation in the Food and Beverage Industry

The food and beverage industry is a cornerstone of the global economy, with an ever-growing demand for efficiency, consistency, and safety. Automation has emerged as a transformative force in this sector, offering a multitude of advantages that benefit producers, consumers, and the environment alike. In this article, we will explore the myriad benefits that automation brings to the food and beverage industry, supported by compelling statistics and insights.

Enhanced Productivity and Efficiency

One of the most significant benefits of automation in the food and beverage industry is the substantial increase in productivity and efficiency. Automated systems can operate 24/7 without the need for breaks, vacations, or shift changes, leading to a dramatic uptick in production rates. For instance, a study by the Association for Packaging and Processing Technologies (PMMI) revealed that automation could increase production by up to 20%. This is a game-changer for businesses looking to scale up and meet the demands of a growing population.

- Continuous operation capabilities

- Reduction in production cycle times

- Streamlined processes with minimal human intervention

Consistency and Quality Control

Automation ensures that each product is manufactured to the same specifications and standards, leading to a consistent quality that consumers can trust. Automated systems are programmed to follow precise recipes and protocols, reducing the likelihood of human error. This consistency is crucial for maintaining brand reputation and customer loyalty. According to a report by the Food Safety Magazine, automation has been instrumental in improving quality control, with error rates dropping by as much as 50% in automated facilities.

- Uniform product quality

- Reduced risk of contamination and human error

- Improved adherence to regulatory standards

Cost Savings and Return on Investment

While the initial investment in automation technology can be significant, the long-term cost savings are substantial. Automated systems can reduce labor costs, minimize waste, and optimize resource use. A study by the McKinsey Global Institute estimates that automation could lead to a 0.8 to 1.4% increase in global GDP annually, with significant contributions from the food and beverage sector. These savings can be reinvested into the business, driving innovation and growth.

- Lower labor expenses over time

- Decreased material waste

- Energy-efficient operations

Improved Worker Safety

Automation reduces the need for workers to perform dangerous or repetitive tasks, thereby decreasing the risk of workplace injuries. Automated equipment can handle high-temperature cooking, sharp cutting instruments, and heavy lifting, protecting employees from potential hazards. The Occupational Safety and Health Administration (OSHA) reports that automation has played a role in reducing the number of workplace accidents in the manufacturing sector.

- Reduction in manual labor for hazardous tasks

- Lower incidence of repetitive strain injuries

- Enhanced compliance with safety regulations

Flexibility and Scalability

Modern automation systems offer incredible flexibility, allowing food and beverage manufacturers to quickly adapt to changing market trends or consumer preferences. With programmable equipment, it’s possible to switch between product lines with minimal downtime. This scalability is essential for businesses that need to respond rapidly to seasonal demands or new opportunities. The International Society of Automation highlights that flexible automation solutions can reduce product changeover times by up to 50%.

- Quick adaptation to new products or packaging

- Scalable production to meet fluctuating demands

- Capability to customize orders with ease

Environmental Sustainability

Automation can also contribute to more sustainable production practices. By optimizing processes and reducing waste, automated systems help minimize the industry’s environmental footprint. Energy-efficient machines and precise ingredient handling result in less resource consumption and lower emissions. The Environmental Protection Agency (EPA) acknowledges the role of automation in promoting sustainability within the manufacturing sector.

- Reduced energy and water usage

- Less food waste through precise processing

- Lower carbon emissions from optimized operations

Conclusion: Embracing the Future of Food and Beverage Production

In conclusion, the advantages of automation in the food and beverage industry are clear and multifaceted. From enhancing productivity and ensuring consistent quality to reducing costs and improving worker safety, automation is an indispensable tool for modern manufacturers. Additionally, the flexibility and environmental benefits that come with automated systems make them a wise investment for any forward-thinking business. As the industry continues to evolve, embracing automation will be key to staying competitive and meeting the needs of a growing global population.

Discover ETprotein’s High-Quality Protein Products

As the food and beverage industry leverages the power of automation, the demand for high-quality ingredients like proteins continues to rise. ETprotein is at the forefront of supplying premium protein products that cater to this demand. Their extensive range of organic bulk vegan proteins and L-(+)-Ergothioneine (EGT) is ideal for businesses looking to enhance their offerings with non-GMO, allergen-free ingredients. With a commitment to quality and customer satisfaction, ETprotein is the go-to source for all your protein needs in an automated and efficient food and beverage industry.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.