Advantages Of Robotics And Automation In The Food Industry

-

Table of Contents

Revolutionizing the Food Industry: The Advantages of Robotics and Automation

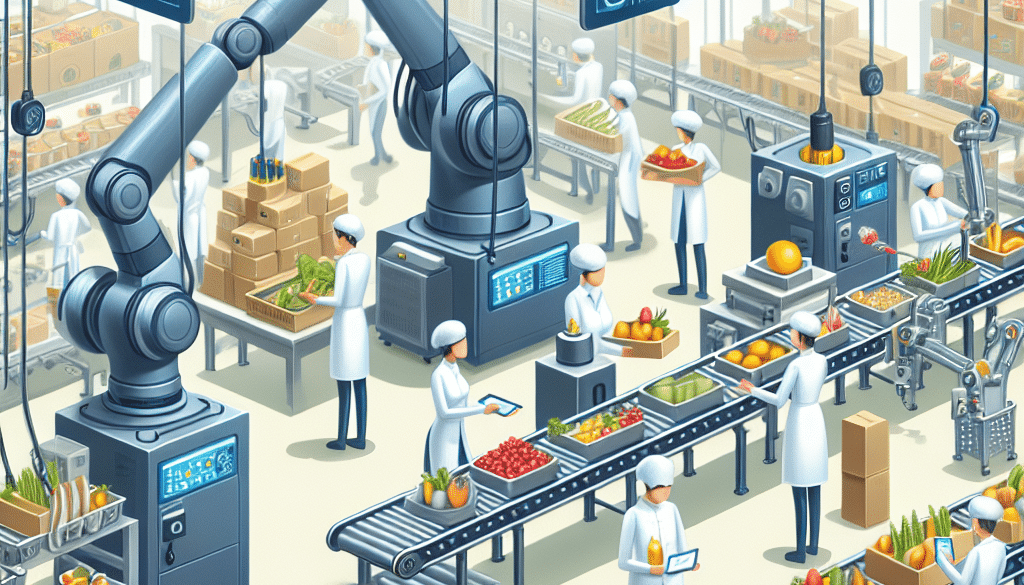

The food industry is undergoing a significant transformation, thanks to the integration of robotics and automation. This technological revolution is not just a futuristic concept but a present-day reality that is reshaping how food is produced, processed, and distributed. In this article, we will explore the numerous advantages that robotics and automation bring to the food industry, supported by statistics and insights that highlight their impact.

Enhanced Efficiency and Productivity

One of the most significant benefits of robotics and automation in the food industry is the substantial increase in efficiency and productivity. Automated systems can operate 24/7 without the need for breaks, vacations, or shift changes, leading to a dramatic uptick in production rates. For instance, a study by the Association for Packaging and Processing Technologies (PMMI) revealed that automation could increase production by up to 20%. This is particularly advantageous during peak demand periods, where the ability to rapidly scale up production can be the difference between meeting or missing market needs.

- Consistent operation without fatigue or human error

- Ability to work in harsh or dangerous environments

- Increased output with consistent quality

Improved Food Safety and Hygiene

Food safety is paramount, and robotics and automation offer significant improvements in this area. Automated systems minimize human contact with food products, thereby reducing the risk of contamination. According to the Centers for Disease Control and Prevention (CDC), about 48 million people get sick from foodborne illnesses each year in the United States alone. Robotics can help lower these numbers by ensuring a more sterile environment and precise handling of food items.

- Reduction in human contact with food products

- Consistent adherence to hygiene standards

- Automated cleaning and sterilization of equipment

Cost Savings and Reduced Waste

While the initial investment in robotics and automation can be substantial, the long-term cost savings are undeniable. Automated systems lead to reduced labor costs, as fewer workers are needed to perform the same amount of work. Moreover, precision technology means that food processing can be done with minimal waste, translating to cost savings and environmental benefits. The Food and Agriculture Organization of the United Nations (FAO) estimates that one-third of all food produced for human consumption is lost or wasted. Automation can help reduce this staggering figure by optimizing production processes.

- Lower long-term operational costs

- Reduced labor expenses

- Minimized food waste through precise processing

Flexibility and Scalability

Robotics and automation systems are highly adaptable, capable of being reprogrammed and retooled for different tasks and products. This flexibility allows food manufacturers to quickly respond to changing consumer preferences and market trends. Additionally, automation makes scaling production up or down more manageable, providing companies with the agility to adapt to fluctuating demand without significant downtime or retraining of staff.

- Quick adaptation to new products and processes

- Easy scalability to meet market demands

- Reduced time and cost for product changeovers

Enhanced Worker Safety

The food industry can be hazardous, with risks ranging from repetitive strain injuries to accidents involving heavy machinery. Robotics and automation can take over dangerous or ergonomically challenging tasks, thereby reducing the risk of workplace injuries. The Occupational Safety and Health Administration (OSHA) reports that the implementation of safety measures, including automation, can reduce injury rates significantly. By delegating high-risk tasks to machines, the food industry can create a safer work environment for its employees.

- Reduction in manual labor for high-risk tasks

- Decreased incidence of workplace injuries

- Creation of safer working conditions

Conclusion

In conclusion, the integration of robotics and automation in the food industry offers a multitude of advantages, including enhanced efficiency, improved food safety, cost savings, flexibility, and worker safety. These benefits not only contribute to a more robust and resilient food supply chain but also pave the way for innovation and growth within the sector. As technology continues to advance, we can expect even more significant improvements in how we produce, process, and distribute food globally.

ETprotein: Your Partner for High-Quality Protein Products

In line with the advancements in the food industry, ETprotein is at the forefront of providing high-quality protein products that cater to the evolving needs of consumers. Their extensive range of organic bulk vegan proteins and L-(+)-Ergothioneine (EGT) products are perfect for businesses looking to enhance their offerings with ingredients that meet the highest standards of quality and safety.

Whether you’re involved in nutraceuticals, sports nutrition, or food and beverage manufacturing, ETprotein’s products can help you stay ahead in a competitive market. With their commitment to non-GMO, allergen-free, and high-purity ingredients, ETprotein is the ideal partner for companies aiming to leverage the benefits of robotics and automation in the food industry.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.