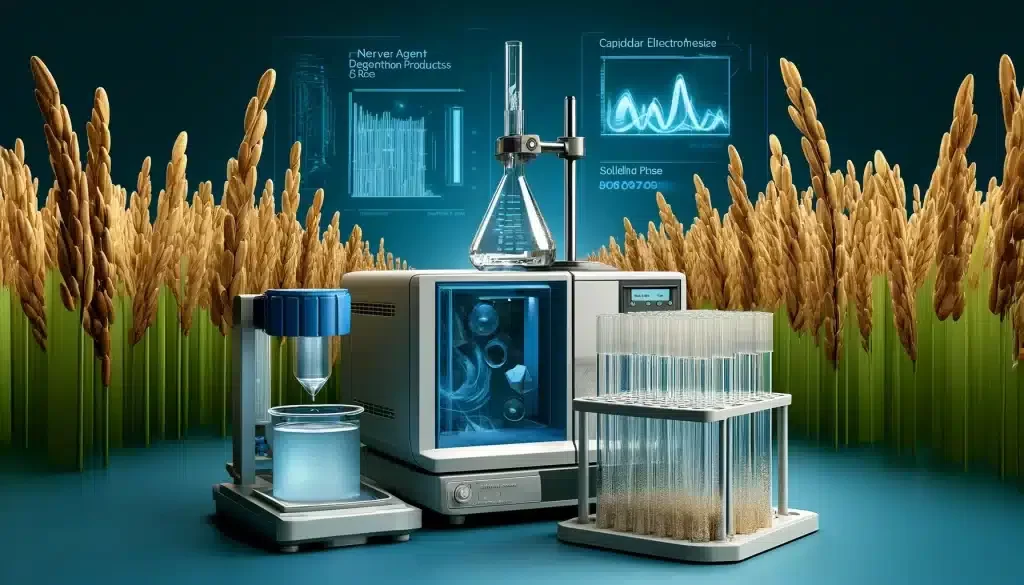

Analysis Of Nerve Agent Degradation Products In Rice By Molecular Imprinting Solid Phase Extraction-Capillary Electrophoresis

Innovative method combines MIP SPE column and capillary electrophoresis to detect nerve agent degradation in rice with high sensitivity and accuracy.

self-made molecularly imprinted polymer solid-phase extraction column was used to separate and purify the nerve agent degradation products in the actual sample rice, and the capillary electrophoresis method was used for detection. The method is simple, accurate, and highly sensitive. The concentration range is 0.2 to 5.0 ¦Ìg/g. , the standard regression curves of the five nerve agent degradation products in rice samples have a good linear relationship, the detection limit is 0.05¦Ìg/g, and the RSD of the method is less than 6.20%.

Introduction to a Novel Detection Method

In recent advancements within the field of analytical chemistry and public health safety, a novel approach has been developed to detect nerve agent degradation products in complex biological matrices. A self-made molecularly imprinted polymer (MIP) solid-phase extraction (SPE) column has been innovatively utilized to separate and purify these degradation products from actual sample matrices, such as rice. This cutting-edge method not only emphasizes the importance of detecting potentially harmful substances in food products but also showcases the effectiveness of combining MIP SPE columns with capillary electrophoresis for detection purposes.

The Role of Molecularly Imprinted Polymers in SPE

Molecularly imprinted polymers are synthetic materials that have been engineered to have specific recognition sites for certain molecules. When these are used in solid-phase extraction columns, they offer unparalleled selectivity and specificity towards the target analytes. This feature is particularly advantageous when dealing with complex matrices, such as food samples, where a myriad of compounds can interfere with the detection and quantification of the analytes of interest.

Combining MIP SPE with Capillary Electrophoresis

In this method, the separation and purification of nerve agent degradation products are achieved with high precision, leveraging the bespoke affinity of the MIP SPE column towards these compounds. Following the extraction, capillary electrophoresis is employed for the detection of the analytes. Capillary electrophoresis is renowned for its efficiency, requiring minimal sample volumes, and its capability to provide rapid and high-resolution separations. This methodological combination not only enhances the sensitivity but also the accuracy of the detection process.

Analytical Performance and Sensitivity

The analytical performance of this innovative method is exceptional, with a concentration range of 0.2 to 5.0 µg/g for the detection of nerve agent degradation products in rice samples. The standard regression curves generated for these analytes demonstrate a commendable linear relationship, indicative of the method’s robustness and reliability. Furthermore, the detection limit of 0.05 µg/g signifies the method’s high sensitivity, making it adept at identifying trace levels of these degradation products, which is crucial for food safety and public health.

Precision and Reproducibility of the Method

The repeatability of the method, as indicated by a relative standard deviation (RSD) of less than 6.20%, underscores its precision and the reproducibility of results. This level of consistency is essential for any analytical technique, especially when dealing with potentially hazardous substances in food products, as it ensures that the detection and quantification of contaminants are accurate and reliable.

Conclusion: Advancements in Food Safety and Public Health

In conclusion, the development and implementation of a self-made molecularly imprinted polymer solid-phase extraction column, coupled with capillary electrophoresis, for the separation, purification, and detection of nerve agent degradation products in rice, represents a significant milestone in the field of analytical chemistry and food safety. This method stands out for its simplicity, accuracy, and high sensitivity, offering a promising solution for the detection of harmful substances in food products. It is a testament to the ongoing innovations in analytical methodologies aimed at protecting public health and ensuring the safety of food supplies around the globe.

For futher details of this article and research, feel free to contact our team for assistance.

Original research was done by Liu Qin, Zhou Yongxin, Meng Zihui, Wang Qingqing, Hu Xuying, Liu Yintang

About ETprotein:

ETprotein, a reputable plant protein vegan protein Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan protein and plant proteins. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, oat protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, various of plant peptides etc. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to get a free sample of their protein products, please contact them and email sales(at)ETprotein.com today.