Application Of Robotics in the Food and Beverages Industry

-

Table of Contents

- Revolutionizing the Food and Beverage Industry with Robotics

- The Rise of Robotics in Food Production

- Enhancing Packaging and Palletizing

- Robotics in Food Service and Delivery

- Challenges and Considerations

- Conclusion: Embracing the Robotic Future

- Enhance Your Food and Beverage Offerings with ETprotein

Revolutionizing the Food and Beverage Industry with Robotics

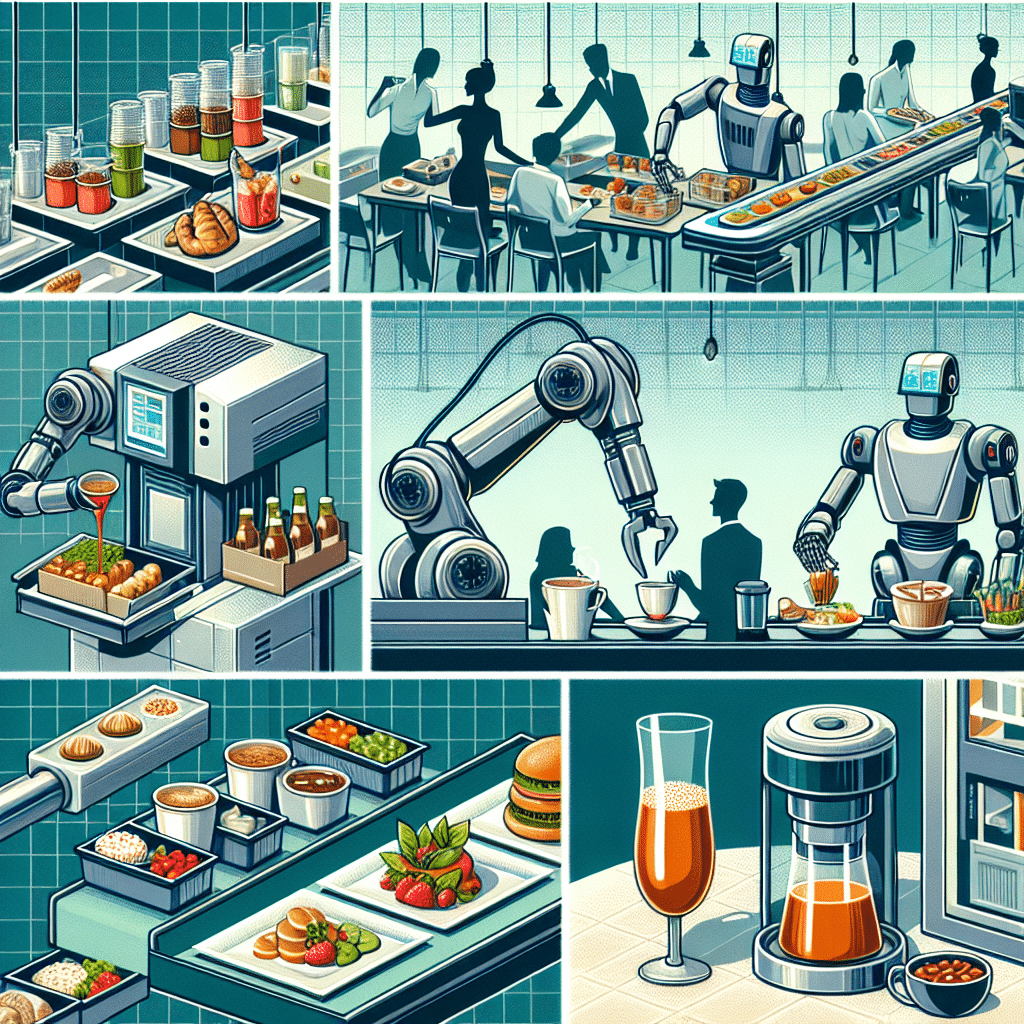

The food and beverage industry is undergoing a significant transformation, with robotics playing a pivotal role in reshaping production, packaging, and service delivery. The integration of robotics in this sector is not only enhancing efficiency but also improving safety, quality, and customization. This article delves into the various applications of robotics in the food and beverage industry, highlighting the benefits and advancements that are setting new standards in the market.

The Rise of Robotics in Food Production

Robotics has found a firm footing in food production, where precision and speed are critical. Automated systems are now capable of handling tasks such as sorting, cutting, and packaging with remarkable accuracy. Here are some key areas where robotics is making an impact:

- Sorting and Grading: Robots equipped with vision systems can sort food items based on size, color, and ripeness. This not only speeds up the process but also ensures consistent quality.

- Butchery and Cutting: Robotic butchers are now able to cut meat with precision, reducing waste and minimizing the risk of contamination.

- Dairy Operations: In dairy farms, robots are used for milking cows, a task that requires consistency and hygiene.

According to a report by the Association for Advancing Automation, robot orders in the food and consumer goods sector increased by 56% in the first quarter of 2021 compared to the previous year. This surge reflects the growing reliance on robotics to meet production demands.

Enhancing Packaging and Palletizing

Robotics has revolutionized the packaging and palletizing processes in the food and beverage industry. Automated systems are now designed to handle delicate items, adapt to various packaging designs, and operate at high speeds. The following are some advancements in this area:

- Flexible Packaging: Robots can now adjust to different packaging sizes and materials, allowing for greater flexibility in product offerings.

- High-Speed Palletizing: Robotic palletizers can stack products faster and more accurately than human workers, optimizing warehouse space and reducing transportation costs.

Statistics from the Robotics Industries Association indicate that the use of robotics in packaging has led to a 30% increase in production speeds on average, demonstrating the significant impact of automation on operational efficiency.

Robotics in Food Service and Delivery

The application of robotics extends beyond production and packaging to the front lines of food service and delivery. Here’s how robots are changing the game:

- Automated Cooking: Robotic chefs are now capable of preparing complex dishes, ensuring consistency and freeing up human chefs for more creative tasks.

- Service Robots: In restaurants, robots are being used to greet customers, take orders, and even serve food, enhancing the dining experience.

- Delivery Drones and Robots: Companies are experimenting with drones and autonomous vehicles for food delivery, aiming to reduce delivery times and costs.

A study by McKinsey & Company predicts that by 2025, up to 25% of food deliveries could be carried out by drones or autonomous vehicles, highlighting the potential for robotics to transform the food service industry.

Challenges and Considerations

While the benefits of robotics in the food and beverage industry are clear, there are challenges to consider:

- Initial Investment: The cost of implementing robotic systems can be high, though it is often offset by long-term savings and increased productivity.

- Workforce Impact: The introduction of robots can lead to job displacement, necessitating retraining and redeployment of workers.

- Technical Maintenance: Robotic systems require regular maintenance and technical support to ensure uninterrupted operation.

Despite these challenges, the overall trend indicates a growing acceptance and reliance on robotics within the industry.

Conclusion: Embracing the Robotic Future

The application of robotics in the food and beverage industry is not just a passing trend but a fundamental shift towards greater efficiency, safety, and innovation. From production to packaging, and from service to delivery, robotics is enabling companies to meet the evolving demands of consumers while maintaining high standards of quality. As technology continues to advance, we can expect even more sophisticated robotic solutions to emerge, further revolutionizing the way we produce, package, and enjoy food and beverages.

Enhance Your Food and Beverage Offerings with ETprotein

If you’re looking to elevate your food and beverage products with high-quality protein ingredients, consider ETprotein’s range of organic bulk vegan proteins and L-(+)-Ergothioneine (EGT). Their products, including Organic rice protein, clear rice protein, pea protein, and more, are characterized by a neutral taste, non-GMO, allergen-free attributes, and high purity levels. Suitable for various applications, ETprotein’s offerings can help you meet the growing demand for plant-based and functional foods in today’s market.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.