Ashwagandha Insights: 4 Manufacturing Must-Knows

-

Table of Contents

Ashwagandha Insights: Essential Manufacturing Know-Hows

Ashwagandha, also known as Withania somnifera, is an ancient medicinal herb that has been used for over 3,000 years to relieve stress, increase energy levels, and improve concentration. In recent years, the global demand for ashwagandha has surged, making it a staple in the health and wellness industry. As manufacturers look to capitalize on this trend, there are several critical factors to consider ensuring the production of high-quality ashwagandha supplements. This article delves into four manufacturing must-knows for ashwagandha, providing valuable insights for producers and consumers alike.

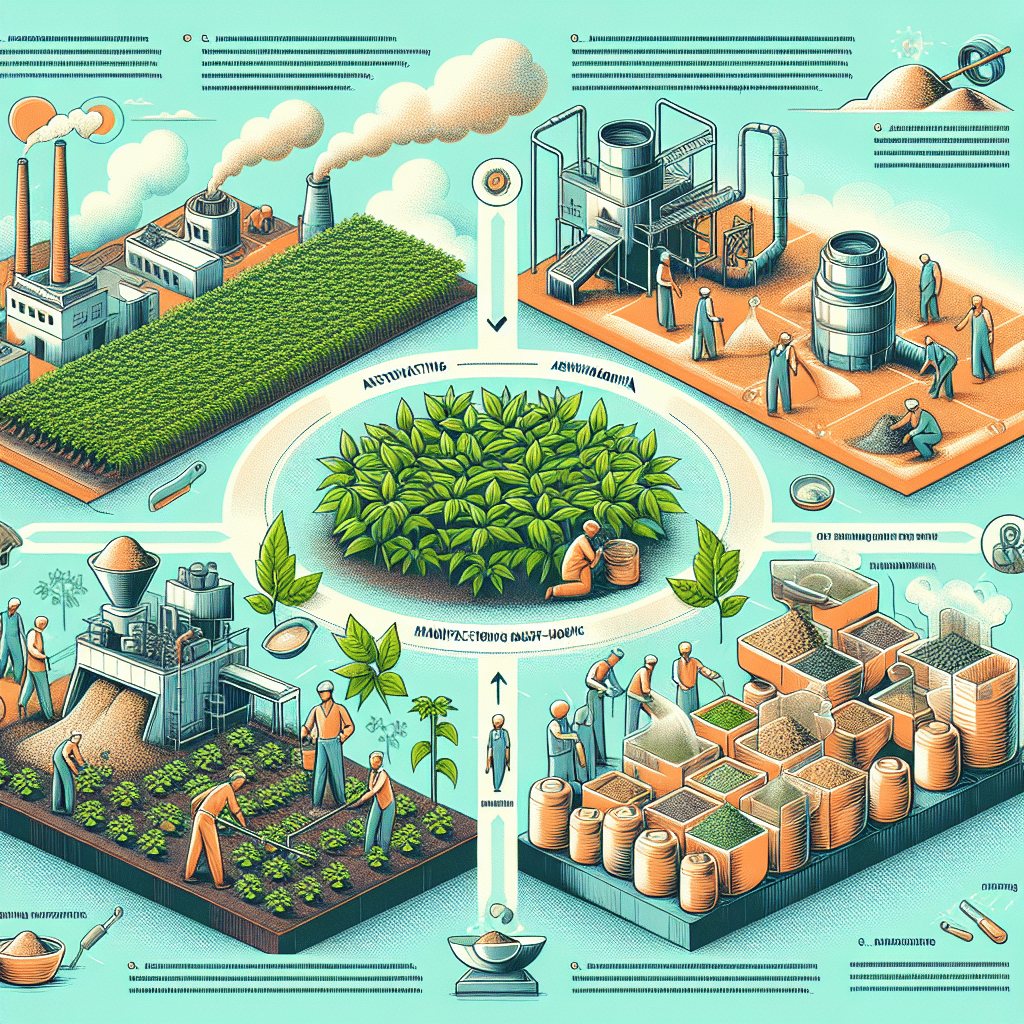

1. Sourcing and Quality of Raw Materials

The quality of ashwagandha supplements begins with the raw materials. Ashwagandha is typically grown in the drier regions of India, Nepal, China, and Yemen. Manufacturers must ensure that the plants are cultivated in optimal conditions to maximize the potency of the active compounds, known as withanolides.

- Organic Farming Practices: Organic certification is a significant factor in the sourcing process. Organic ashwagandha is grown without the use of synthetic pesticides and fertilizers, which can be crucial for consumers seeking natural and uncontaminated products.

- Supplier Relationships: Establishing strong relationships with farmers and suppliers is essential. This ensures a consistent supply of high-quality roots and leaves and allows manufacturers to trace the product back to its source, ensuring transparency and trust.

- Testing for Active Compounds: Rigorous testing of withanolide content is necessary to guarantee the efficacy of the final product. Manufacturers should conduct standardized tests to measure the levels of these compounds.

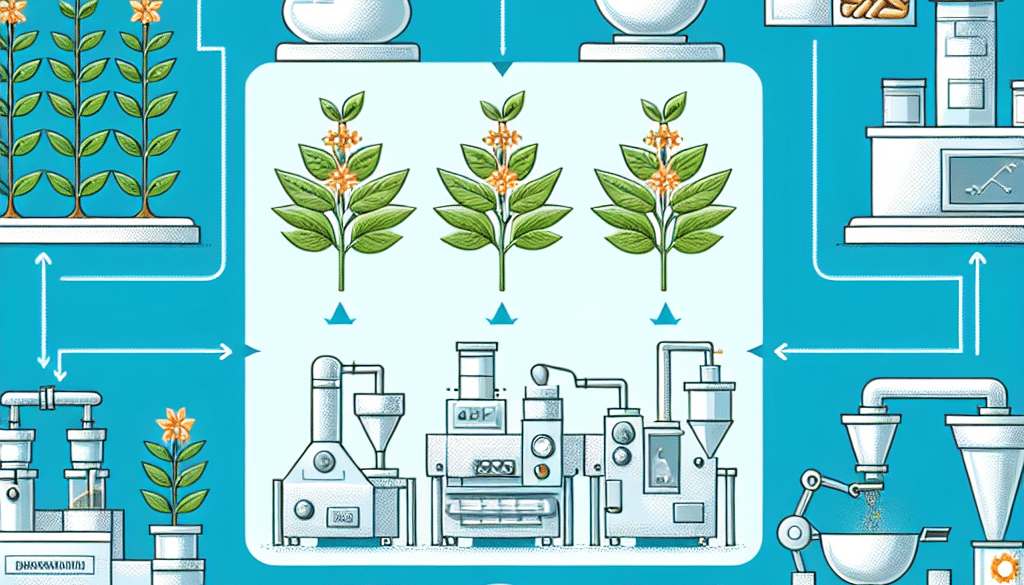

2. Extraction and Standardization Processes

Extracting the bioactive compounds from ashwagandha roots and leaves is a critical step in manufacturing. The method of extraction can significantly affect the quality and efficacy of the final product.

- Extraction Methods: Techniques such as supercritical CO2 extraction, hydroethanolic extraction, and water extraction are commonly used. Each method has its benefits and drawbacks, and the choice depends on the desired withanolide content and product form.

- Standardization: To ensure consistent potency across batches, manufacturers must standardize the extract to a specific percentage of withanolides. This process involves adjusting the concentration of active compounds to meet the label claim.

- Quality Control: Throughout the extraction and standardization processes, quality control measures must be in place to monitor for contaminants, such as heavy metals, microbes, and aflatoxins.

3. Formulation and Delivery Systems

The formulation of ashwagandha supplements is crucial for bioavailability and consumer preference. Manufacturers must consider the delivery system that best suits the active ingredients and target market.

- Capsules and Tablets: These are the most common forms of ashwagandha supplements. They offer precise dosing and convenience but require careful consideration of excipients and binders to ensure stability and efficacy.

- Powders and Liquids: Ashwagandha can also be incorporated into powders and liquid extracts. These forms may offer faster absorption and are suitable for those who have difficulty swallowing pills.

- Innovative Delivery Systems: Liposomal delivery systems and nanoemulsions are emerging as ways to enhance the bioavailability of withanolides. Manufacturers exploring these options must invest in research and development to validate their effectiveness.

4. Compliance with Regulatory Standards

Adhering to regulatory standards is non-negotiable in the manufacturing of ashwagandha supplements. Compliance ensures product safety, efficacy, and legal marketability.

- Good Manufacturing Practices (GMP): Manufacturers must follow GMP guidelines, which cover all aspects of production, from the cleanliness of facilities to the training of staff.

- Labeling Requirements: Accurate labeling is essential. This includes listing all active and inactive ingredients, dosage instructions, and any potential allergens.

- Third-Party Certifications: Obtaining certifications from organizations such as NSF International, USP, or the Non-GMO Project can provide additional assurance of quality and safety to consumers.

Conclusion

In conclusion, the manufacturing of ashwagandha supplements requires meticulous attention to detail at every stage, from sourcing high-quality raw materials to ensuring compliance with regulatory standards. By focusing on these four must-knows, manufacturers can produce effective and safe products that meet the growing consumer demand for natural health solutions. As the market for ashwagandha continues to expand, those who invest in quality and transparency will likely emerge as leaders in this segment.

Enhance Your Health Regimen with ETprotein’s Premium Protein Products

If you’re looking to complement your ashwagandha intake with high-quality protein, consider ETprotein’s range of organic bulk vegan proteins. Their products, including Organic rice protein, clear rice protein, pea protein, and more, are characterized by a neutral taste, non-GMO, and allergen-free attributes. ETprotein’s offerings cater to a diverse range of industries and are ideal for those seeking to enhance their health and wellness regimen.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.