Automating the Food Manufacturing Process with Robots

-

Table of Contents

- Revolutionizing Food Manufacturing: The Rise of Robotic Automation

- The Role of Robots in Food Manufacturing

- Benefits of Automating with Robots

- Challenges in Implementing Robotic Automation

- Statistics Supporting the Growth of Robotics in Food Manufacturing

- Case Studies: Success Stories of Robotic Automation

- Conclusion: Embracing the Robotic Future in Food Manufacturing

- ETprotein: Enhancing Food Manufacturing with High-Quality Protein Products

Revolutionizing Food Manufacturing: The Rise of Robotic Automation

The food manufacturing industry is undergoing a significant transformation, with automation and robotics playing a pivotal role in shaping its future. The integration of robots into the food production process is not just a trend but a necessity to meet the growing demand for food, ensure consistent quality, and improve safety standards. This article delves into the ways in which robots are automating the food manufacturing process, the benefits they bring, and the challenges they pose.

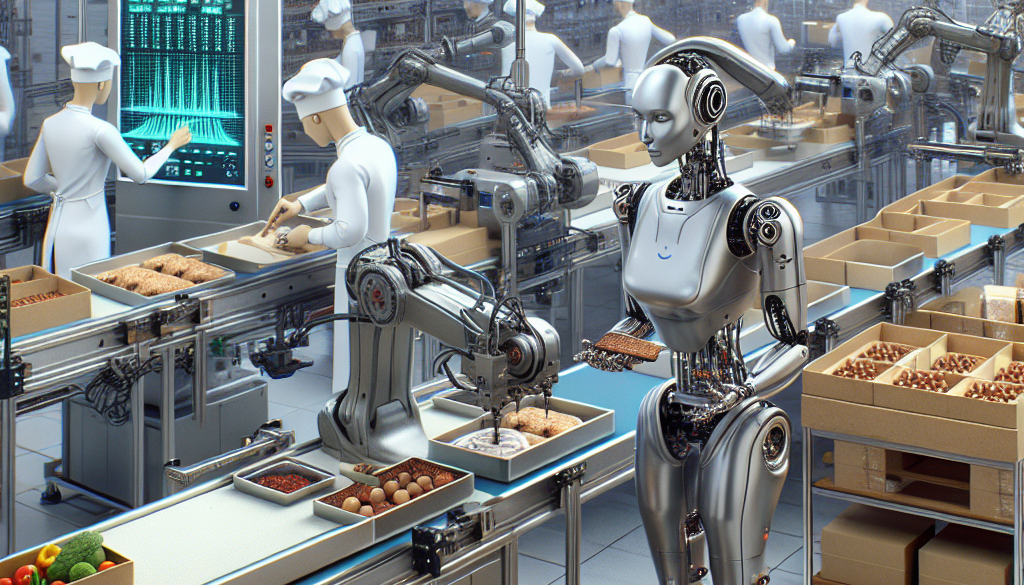

The Role of Robots in Food Manufacturing

Robots are increasingly being deployed across various stages of food production, from processing raw materials to packaging finished products. They are designed to handle repetitive tasks with precision and speed, which is crucial in an industry that requires high throughput and consistency.

- Sorting and Grading: Robots equipped with vision systems can sort and grade food items based on size, color, and ripeness.

- Processing: Robotic arms can perform tasks such as cutting, slicing, and deboning with accuracy, reducing waste and improving yield.

- Packaging: Automated systems can package products quickly and efficiently, minimizing human contact and potential contamination.

- Palletizing: Robots can stack packaged goods onto pallets, ready for distribution, optimizing space and reducing labor costs.

Benefits of Automating with Robots

The adoption of robotics in food manufacturing offers numerous advantages, including enhanced productivity, improved worker safety, and better product quality.

- Increased Efficiency: Robots can operate 24/7 without fatigue, significantly boosting production rates.

- Consistency and Quality Control: Automation ensures uniformity in food products, meeting strict quality standards.

- Worker Safety: Robots can take over dangerous or physically demanding tasks, reducing workplace injuries.

- Cost Savings: Although the initial investment may be high, robots can lead to long-term savings by reducing labor and operational costs.

Challenges in Implementing Robotic Automation

Despite the clear benefits, there are challenges that food manufacturers face when integrating robots into their processes.

- High Initial Investment: The cost of robotic systems and the associated infrastructure can be prohibitive for some manufacturers.

- Technical Expertise: Skilled personnel are required to operate and maintain robotic systems, which can be a barrier for companies lacking in-house expertise.

- Flexibility: Robots are traditionally less adaptable than human workers, making it difficult to switch between different types of products or processes quickly.

Statistics Supporting the Growth of Robotics in Food Manufacturing

Recent statistics highlight the rapid growth and potential of robotics in the food industry:

- According to a report by Meticulous Research, the food robotics market is expected to reach $3.1 billion by 2025, growing at a CAGR of 12.7% from 2019 to 2025.

- The same report indicates that the primary drivers for this growth include increasing food safety regulations, the need for improved productivity, and the rising demand for packaged foods.

- A study by the Association for Packaging and Processing Technologies (PMMI) shows that 94% of food manufacturers are using or considering using robotics in their operations.

Case Studies: Success Stories of Robotic Automation

Several food manufacturers have successfully integrated robotics into their operations, demonstrating the tangible benefits of automation.

- A leading dairy company implemented robotic palletizing systems, resulting in a 60% increase in palletizing speed and a significant reduction in labor costs.

- A bakery introduced collaborative robots to handle the delicate task of icing cakes, achieving a consistent finish and reducing product waste.

Conclusion: Embracing the Robotic Future in Food Manufacturing

The integration of robots into the food manufacturing process is an inevitable step towards a more efficient, safe, and sustainable industry. While challenges exist, the benefits of robotic automation are clear, and companies that invest in this technology are likely to see significant returns. As the technology continues to advance, we can expect to see even more innovative applications of robotics in food production.

ETprotein: Enhancing Food Manufacturing with High-Quality Protein Products

In addition to embracing robotic automation, food manufacturers can further enhance their products by incorporating high-quality protein ingredients from ETprotein. ETprotein’s range of organic bulk vegan proteins and L-(+)-Ergothioneine (EGT) can be seamlessly integrated into various food manufacturing processes, offering a neutral taste and allergen-free attributes. Their products are ideal for manufacturers looking to cater to the growing market for nutritious and sustainable food options.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.