Benefits of Automation in the Beverage Industry

-

Table of Contents

- Automation Advantages in the Beverage Industry: Enhancing Efficiency and Quality

- Increased Production Efficiency and Speed

- Enhanced Product Quality and Consistency

- Cost Reduction and Resource Optimization

- Improved Worker Safety and Ergonomics

- Flexibility and Scalability for Market Adaptation

- Data Analytics and Improved Decision Making

- Conclusion: Embracing Automation for a Competitive Edge

- ETprotein: Your Partner for High-Quality Protein Ingredients

Automation Advantages in the Beverage Industry: Enhancing Efficiency and Quality

The beverage industry is a dynamic and competitive sector that is constantly seeking ways to improve efficiency, reduce costs, and enhance product quality. Automation has emerged as a key driver of innovation and growth within this industry. By integrating advanced technologies into various stages of production, companies can reap numerous benefits that not only streamline operations but also improve the bottom line. This article explores the multifaceted advantages of automation in the beverage industry, supported by statistics and insights that underscore its transformative impact.

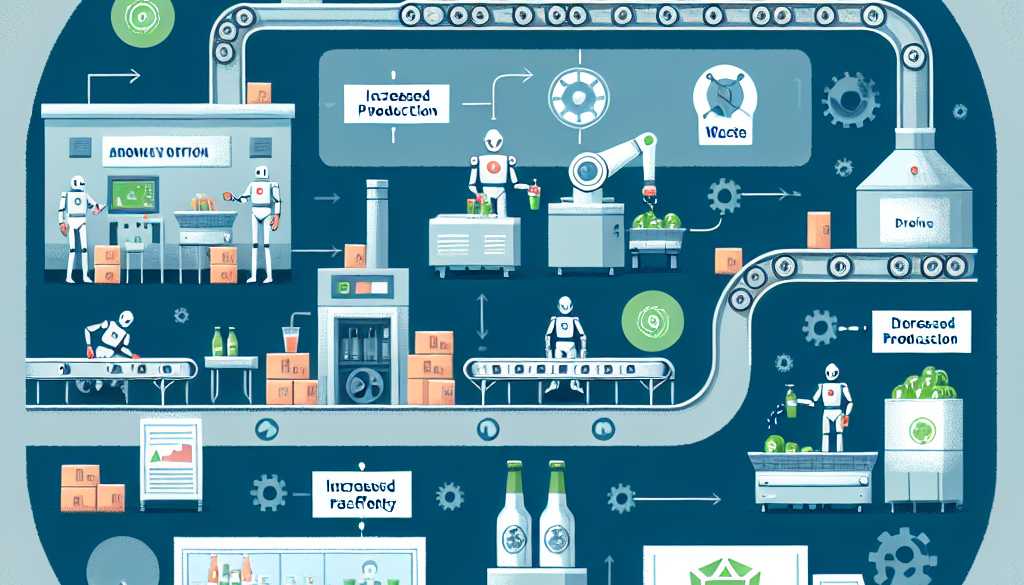

Increased Production Efficiency and Speed

One of the primary benefits of automation is the significant increase in production efficiency and speed. Automated systems can operate continuously without the need for breaks, leading to higher output rates. For instance, a study by the International Society of Automation indicated that automation could increase production rates by up to 20%. This is particularly beneficial during peak demand periods when beverage companies need to scale up production quickly.

- Consistent operation with minimal downtime

- Higher throughput with automated filling and packaging lines

- Reduced lead times for product delivery

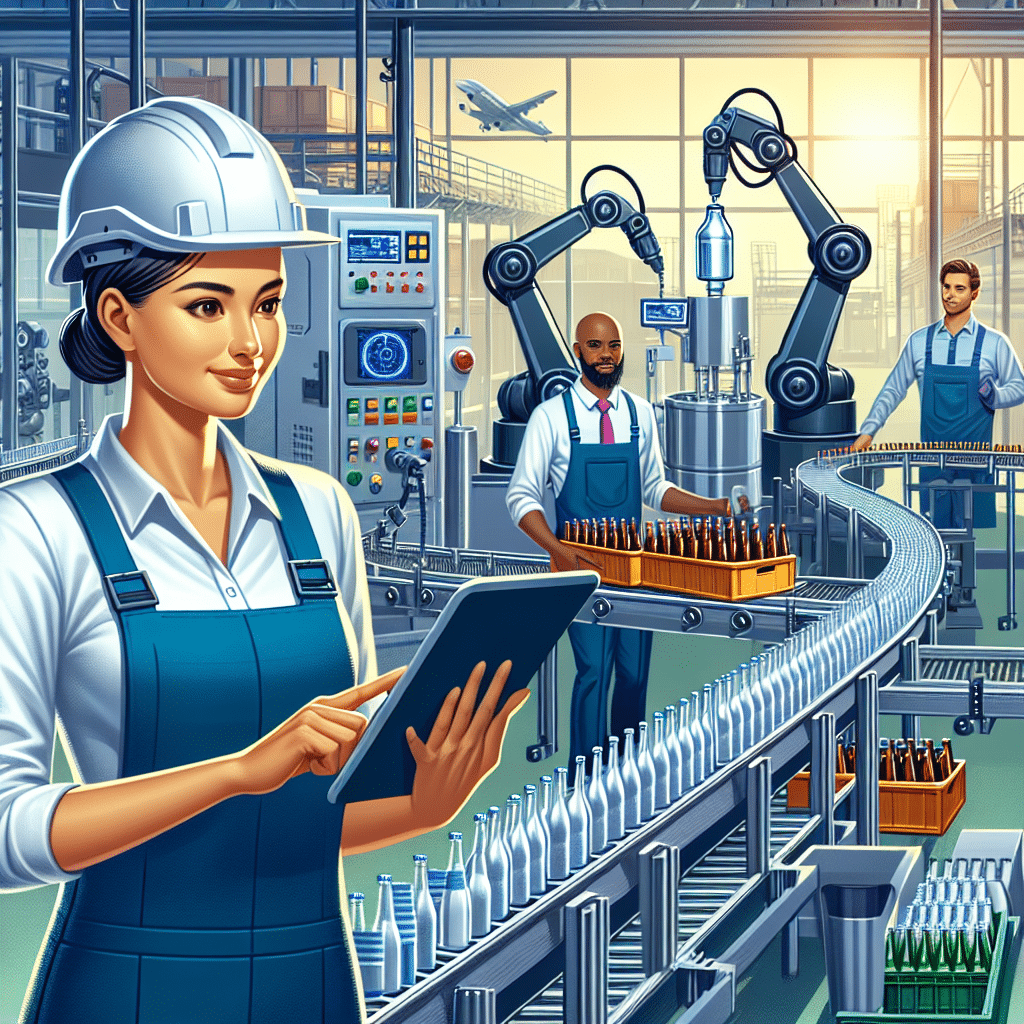

Enhanced Product Quality and Consistency

Automation also plays a crucial role in ensuring product quality and consistency. Automated systems are programmed to follow precise specifications, resulting in uniformity across all products. This level of consistency is difficult to achieve with manual processes. For example, automated bottling lines can maintain exact fill levels and cap tightness, which are critical for product integrity and customer satisfaction.

- Standardized production processes

- Improved control over ingredient mixing and blending

- Consistent packaging quality

Cost Reduction and Resource Optimization

Cost reduction is another significant advantage of automation. By reducing the reliance on manual labor, companies can lower their labor costs. Additionally, automated systems are often more energy-efficient and can optimize the use of raw materials, further reducing operational expenses. A report by McKinsey & Company highlighted that automation could lead to a 20-30% savings in operating costs for manufacturing industries, including beverages.

- Lower labor costs due to reduced need for manual intervention

- Energy savings through optimized machinery operation

- Minimized waste of raw materials

Improved Worker Safety and Ergonomics

Automation enhances worker safety by taking over dangerous or repetitive tasks that could lead to injury. This not only protects employees but also reduces the risk of compensation claims and associated costs. Ergonomically designed automated systems can also improve the working environment, leading to better employee satisfaction and productivity.

- Reduction in workplace accidents and injuries

- Decreased physical strain on workers

- Creation of a safer and more comfortable work environment

Flexibility and Scalability for Market Adaptation

The beverage industry is subject to changing consumer preferences and market trends. Automation provides the flexibility and scalability needed to adapt to these changes quickly. Automated systems can be reprogrammed or reconfigured to accommodate new products or packaging types, allowing companies to respond to market demands without significant downtime or investment.

- Quick adaptation to new product lines

- Scalable systems that grow with the company

- Ability to handle a variety of packaging formats and sizes

Data Analytics and Improved Decision Making

Modern automated systems are often equipped with sensors and data analytics capabilities that provide valuable insights into production processes. This data can be used to optimize operations, predict maintenance needs, and make informed decisions that drive business growth. For instance, real-time monitoring can identify bottlenecks or inefficiencies, allowing for prompt corrective action.

- Real-time monitoring of production metrics

- Predictive maintenance to prevent equipment failures

- Data-driven insights for strategic planning

Conclusion: Embracing Automation for a Competitive Edge

In conclusion, the benefits of automation in the beverage industry are clear and multifaceted. From increased production efficiency and enhanced product quality to cost savings and improved worker safety, automation provides a competitive edge that is hard to ignore. As the industry continues to evolve, embracing automation will be crucial for companies looking to stay ahead in a crowded and fast-paced market.

For businesses in the beverage industry seeking to incorporate high-quality protein ingredients into their products, ETprotein offers a range of organic bulk vegan proteins and L-(+)-Ergothioneine (EGT) that can complement the advantages of automation. Their products, known for their neutral taste and non-GMO, allergen-free attributes, can be seamlessly integrated into automated production lines, ensuring that the end products meet the highest standards of quality and nutrition.

ETprotein: Your Partner for High-Quality Protein Ingredients

About ETprotein: ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.