Benefits of Robotics in the Food Industry

-

Table of Contents

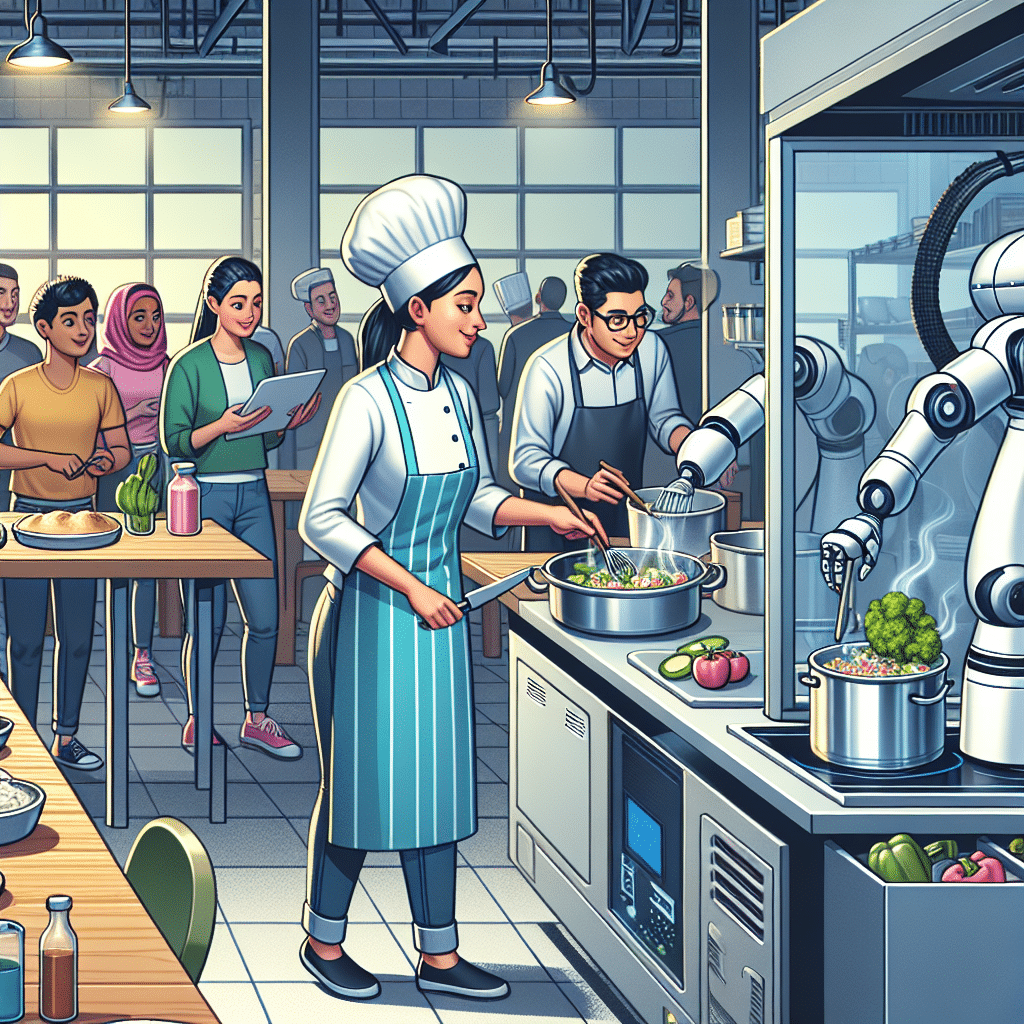

Robotics Revolutionizing the Food Industry: Key Benefits Explored

The food industry is undergoing a significant transformation, with robotics playing a pivotal role in reshaping production, packaging, and service delivery. The integration of robotics in the food sector is not just a futuristic concept but a present-day reality that is enhancing efficiency, safety, and sustainability. This article delves into the numerous benefits that robotics bring to the food industry, supported by statistics and insights that underscore their growing importance.

Enhanced Efficiency and Productivity

One of the most significant advantages of robotics in the food industry is the substantial increase in efficiency and productivity. Robots are designed to perform repetitive tasks with precision and without fatigue, which translates to higher output rates and consistent product quality. For instance, a study by the Association for Packaging and Processing Technologies (PMMI) indicates that robotics can increase production speeds by up to 50%. This is particularly beneficial in high-volume food processing environments where time and consistency are critical factors.

- Robots can operate 24/7, reducing downtime and increasing production cycles.

- Automated systems streamline processes, from sorting ingredients to packaging finished products.

- Robotic arms can handle delicate items, such as fruits and pastries, without causing damage, ensuring high-quality presentation.

Improved Food Safety and Hygiene

Food safety is paramount in the industry, and robotics contribute significantly to maintaining high hygiene standards. By minimizing human contact with food products, the risk of contamination is greatly reduced. According to the Centers for Disease Control and Prevention (CDC), about 48 million people get sick from foodborne illnesses each year in the United States alone. Robotics can help lower these numbers by providing a more controlled and sanitized production environment.

- Robots are designed to comply with strict hygiene and cleaning protocols, reducing the risk of foodborne diseases.

- Automated systems can be equipped with sensors to detect and remove substandard or contaminated products.

- Robotic packaging ensures that food is sealed and protected from external contaminants effectively.

Cost Reduction and ROI

While the initial investment in robotics may be substantial, the long-term cost savings and return on investment (ROI) are significant. Robotics reduce labor costs, as fewer workers are needed to perform the same amount of work. Moreover, the precision of robots leads to less waste and more efficient use of raw materials. A report by the International Federation of Robotics (IFR) shows that the average robot payback period in the food industry is between 12 to 18 months, demonstrating the financial viability of robotics in this sector.

- Robots can help cut down on labor expenses, especially in regions with higher wage rates.

- Energy-efficient robots contribute to lower utility costs.

- Reduced material waste contributes to cost savings and environmental sustainability.

Flexibility and Scalability

The food industry requires a high degree of flexibility to adapt to changing consumer demands and seasonal variations. Robotics systems are highly adaptable and can be reprogrammed to handle different tasks, products, or packaging types. This flexibility allows food manufacturers to quickly pivot and scale operations up or down as needed without significant downtime or additional training costs.

- Quick-change tooling and software updates allow robots to switch between tasks with minimal interruption.

- Scalable robotic systems can grow with the business, accommodating increased production volumes without the need for extensive facility expansions.

- Robots can be integrated with artificial intelligence (AI) to enhance their adaptability and decision-making capabilities.

Addressing Labor Shortages

The food industry often faces challenges in recruiting and retaining skilled labor, especially for repetitive and physically demanding tasks. Robotics offer a solution to this issue by filling gaps in the workforce and performing tasks that are difficult to staff. This not only alleviates the pressure on finding labor but also allows human workers to focus on more complex and rewarding roles within the industry.

- Robots can operate in environments that may be hazardous or uncomfortable for human workers, such as extreme temperatures or handling dangerous equipment.

- Automation can help stabilize production capacity, even during periods of labor shortages or high employee turnover.

- By taking on mundane tasks, robots enable human employees to engage in more strategic, creative, or customer-focused activities.

Conclusion

The integration of robotics in the food industry offers a multitude of benefits, including enhanced efficiency, improved food safety, cost reduction, flexibility, and a solution to labor shortages. As technology continues to advance, the role of robotics in food production and processing is set to become even more integral. Companies that embrace this technological revolution are likely to see significant improvements in their operations, product quality, and bottom line.

Discover ETprotein’s High-Quality Protein Products

In line with the technological advancements in the food industry, ETprotein is at the forefront of providing premium protein products that cater to the evolving needs of consumers. Their extensive range of organic bulk vegan proteins and L-(+)-Ergothioneine (EGT) is ideal for businesses looking to enhance their food offerings with high-quality, sustainable ingredients.

Whether you’re involved in sports nutrition, weight management, dietary supplements, or infant formula, ETprotein’s products are designed to meet the highest standards of taste, purity, and nutritional value. By incorporating ETprotein’s protein solutions into your food products, you can ensure that your offerings stand out in a competitive market.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.