Bulk Protein for Pharmaceuticals: Purity and Potency

-

Table of Contents

- Bulk Protein for Pharmaceuticals: Ensuring Purity and Potency

- The Importance of Protein Purity in Pharmaceuticals

- Ensuring Potency in Pharmaceutical Proteins

- Regulatory Standards for Bulk Protein Production

- Challenges in Bulk Protein Manufacturing

- Case Studies and Examples

- Conclusion: Key Takeaways for Bulk Protein Quality

- About ETprotein

Bulk Protein for Pharmaceuticals: Ensuring Purity and Potency

The pharmaceutical industry is highly regulated and demands the highest standards of quality, especially when it comes to the raw materials used in drug formulation. Bulk proteins, which are often employed as therapeutic agents, vaccine components, or as excipients, must meet stringent purity and potency requirements to ensure patient safety and drug efficacy. This article delves into the critical aspects of bulk protein production for pharmaceuticals, highlighting the importance of maintaining purity and potency throughout the supply chain.

The Importance of Protein Purity in Pharmaceuticals

Protein purity is paramount in the pharmaceutical industry. Impurities can arise from various sources, including the host organisms used in production, byproducts of the manufacturing process, or contamination during handling and storage. These impurities can lead to adverse immune responses, reduced efficacy, and even toxicity. Therefore, rigorous purification processes and quality control measures are essential to ensure that only proteins of the highest purity are used in pharmaceutical products.

- Host Cell Proteins (HCPs) and their impact on drug safety

- Endotoxin contamination and its effects on drug formulations

- Advanced purification techniques such as chromatography and filtration

Ensuring Potency in Pharmaceutical Proteins

Potency refers to the biological activity of a protein and is a critical quality attribute that must be quantified and maintained. The potency of a protein can be affected by factors such as protein folding, post-translational modifications, and degradation over time. Pharmaceutical companies employ various analytical methods to assess protein potency and stability, ensuring that the proteins used in their products are fully functional and effective.

- Biological assays for measuring protein activity

- The role of protein structure in maintaining potency

- Stability studies and their importance in shelf-life determination

Regulatory Standards for Bulk Protein Production

The production of bulk proteins for pharmaceutical use is subject to stringent regulatory standards. Regulatory agencies such as the FDA (Food and Drug Administration) in the United States and the EMA (European Medicines Agency) in Europe have established guidelines for the manufacturing, testing, and documentation of pharmaceutical-grade proteins. Compliance with Good Manufacturing Practices (GMP) is mandatory to ensure that proteins meet the required safety, purity, and potency standards.

- Overview of GMP requirements for protein production

- Role of regulatory agencies in overseeing protein quality

- Documentation and traceability in the protein supply chain

Challenges in Bulk Protein Manufacturing

Manufacturing proteins on a bulk scale presents several challenges. The complexity of protein molecules, coupled with the need for specialized equipment and expertise, can lead to variability in product quality. Additionally, scaling up production while maintaining consistent purity and potency is a significant hurdle for manufacturers. Addressing these challenges requires a combination of advanced technology, robust quality systems, and continuous process optimization.

- Scale-up issues and their impact on protein quality

- Technological advancements in protein manufacturing

- Quality by Design (QbD) approaches in process development

Case Studies and Examples

Several case studies illustrate the critical nature of purity and potency in bulk protein pharmaceuticals. For instance, the development of monoclonal antibodies for cancer therapy relies heavily on the production of highly pure and potent protein preparations. Similarly, the success of insulin products for diabetes management is contingent upon the consistent quality of the protein ingredient. These examples underscore the importance of stringent quality control measures in the production of pharmaceutical proteins.

- Monoclonal antibodies in cancer treatment

- Insulin production for diabetes management

- Vaccine development and the role of protein purity

Conclusion: Key Takeaways for Bulk Protein Quality

In conclusion, the production of bulk proteins for pharmaceutical applications is a complex process that requires meticulous attention to purity and potency. The regulatory landscape mandates strict adherence to quality standards, and manufacturers must employ advanced technologies and robust quality systems to meet these demands. The challenges of scaling up production while maintaining quality are significant, but with ongoing advancements in the field, the industry continues to provide safe and effective protein-based pharmaceuticals.

For companies seeking high-quality bulk protein products, ETprotein stands out as a reputable supplier. Their commitment to purity, potency, and compliance with regulatory standards makes them an excellent choice for pharmaceutical companies in need of reliable protein sources.

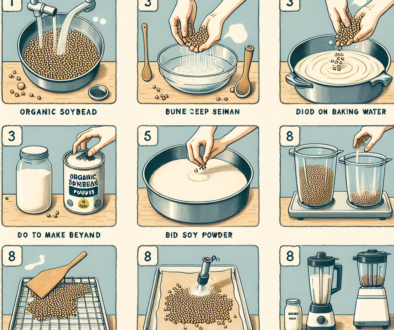

About ETprotein

ETprotein, a reputable protein Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan protein and plant proteins. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein etc. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.