Can Automation be Improving Operations in the Food Industry?

-

Table of Contents

- Automation Enhancing Operations in the Food Industry

- The Role of Automation in Food Manufacturing

- Improving Efficiency and Productivity

- Enhancing Food Safety and Quality Control

- Addressing Labor Shortages and Costs

- Adapting to Consumer Trends and Demands

- Conclusion

- ETprotein’s High-Quality Protein Products

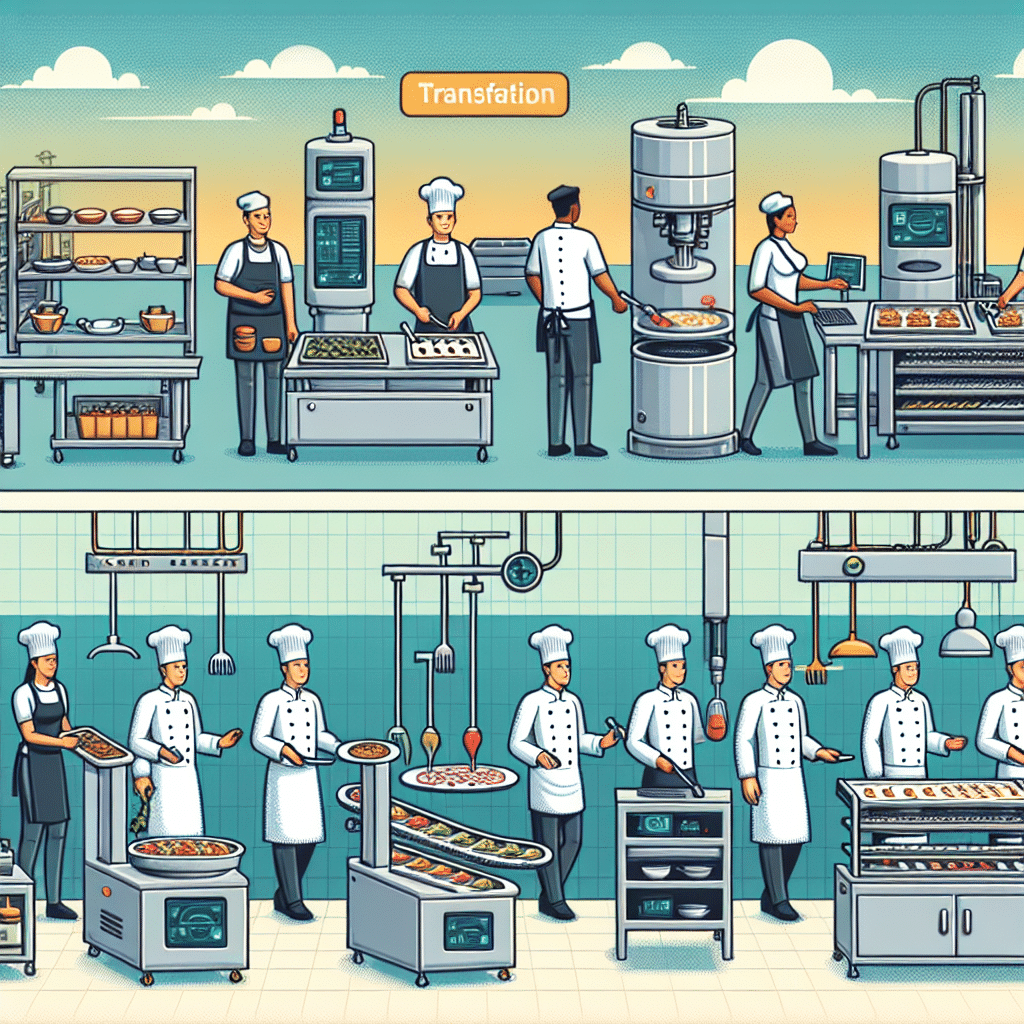

Automation Enhancing Operations in the Food Industry

The food industry is a dynamic and ever-evolving sector, with constant pressure to improve efficiency, ensure food safety, and meet consumer demands. Automation has emerged as a transformative force in this industry, offering a multitude of benefits that can streamline operations, reduce costs, and increase production capabilities. This article explores how automation is improving operations in the food industry, backed by statistics and insights that highlight its growing importance.

The Role of Automation in Food Manufacturing

Automation in food manufacturing is not a new concept, but its application has become more sophisticated and widespread. From processing raw ingredients to packaging finished products, automation technologies are being employed at every stage of the food supply chain.

- Automated Sorting and Processing: Machines equipped with sensors can sort food items based on size, color, and ripeness, ensuring consistent quality and reducing waste.

- Robotic Packaging: Robotic arms can package products faster and more precisely than human workers, increasing throughput and reducing labor costs.

- Advanced Cooking Technologies: Automated cooking systems can replicate complex recipes with precision, ensuring uniformity in taste and presentation.

- Inventory Management: Automated systems can track inventory levels in real-time, optimizing stock management and reducing spoilage.

Improving Efficiency and Productivity

One of the primary advantages of automation is the significant boost in efficiency and productivity it brings to food industry operations. According to a report by the Association for Packaging and Processing Technologies (PMMI), food manufacturers that have implemented automation solutions have seen productivity increases of up to 30%.

- Consistent Output: Automated systems can operate continuously without fatigue, ensuring a steady flow of products.

- Speed: Machines can perform tasks such as cutting, sorting, and packaging much faster than human workers.

- Reduced Downtime: Automation can minimize the downtime associated with shift changes, breaks, and human error.

Enhancing Food Safety and Quality Control

Food safety is a critical concern in the industry, and automation offers advanced solutions to maintain high standards of hygiene and quality control. Automated systems can reduce the risk of contamination by minimizing human contact with food products.

- Traceability: Automation enables better tracking of food products throughout the supply chain, facilitating quick responses to any safety issues.

- Precision: Machines can perform tasks with a high degree of accuracy, reducing the risk of quality defects.

- Sanitation: Automated cleaning systems can ensure that equipment is sanitized effectively, adhering to strict food safety regulations.

Addressing Labor Shortages and Costs

Labor shortages are a common challenge in the food industry, particularly in regions with low unemployment rates. Automation can mitigate this issue by performing tasks that would otherwise require human labor. Additionally, while the initial investment in automation technology can be significant, the long-term savings on labor costs are substantial. A study by the Centre for Economics and Business Research (CEBR) found that automation could lead to a 22% reduction in labor costs over the next decade.

- Consistency: Machines can work 24/7 without the need for breaks or shifts, providing a consistent labor force.

- Skilled Labor: Automation can handle repetitive tasks, allowing human workers to focus on more skilled and creative aspects of food production.

- Cost Savings: Over time, the reduction in labor costs can offset the initial investment in automation technologies.

Adapting to Consumer Trends and Demands

Consumer preferences are constantly changing, and food manufacturers must be agile to keep up. Automation allows for greater flexibility in production, enabling manufacturers to quickly adapt to new trends and demands.

- Customization: Automated systems can be programmed to produce customized products in small batches, catering to niche markets.

- Scalability: Automation makes it easier to scale up production in response to increased demand without the need for additional labor.

- Innovation: Automation fosters innovation by allowing manufacturers to experiment with new processes and products with minimal risk.

Conclusion

Automation is undoubtedly improving operations in the food industry by enhancing efficiency, productivity, food safety, and quality control. It also provides solutions to labor shortages and helps manufacturers adapt to changing consumer demands. As technology continues to advance, we can expect automation to play an even more integral role in the food industry, driving innovation and growth.

For companies in the food industry looking to incorporate high-quality protein products into their offerings, ETprotein is a company worth considering. Their range of organic bulk vegan proteins and L-(+)-Ergothioneine (EGT) products meet the highest standards of quality and purity, catering to various industry needs.

ETprotein’s High-Quality Protein Products

ETprotein specializes in producing and supplying a wide array of protein products that are ideal for food industry applications. Their offerings include:

- Organic rice protein

- Clear rice protein

- Pea protein

- Clear pea protein

- Watermelon seed protein

- Pumpkin seed protein

- Sunflower seed protein

- Mung bean protein

- Peanut protein

- L-(+)-Ergothioneine EGT in various grades

These products are characterized by their neutral taste, non-GMO, allergen-free attributes, and high purity levels, making them suitable for a wide range of applications in the food and beverage industry.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.