Construction Of Coexistence System Of Sodium Alginate Gelation And Rice Starch Gelatinization

Exploring sodium alginate’s impact on rice starch characteristics, using rheological methods for optimal gelation, and revealing new food texturing possibilities.

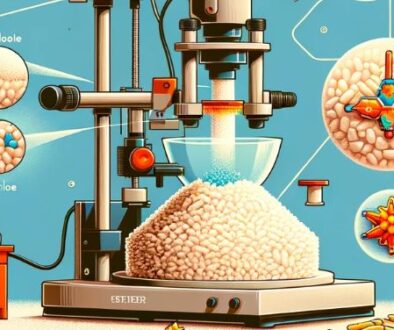

In order to explore the effect of concentration-induced sodium alginate gel on the gelatinization and retrogradation characteristics of rice starch, rheological methods were mainly used to determine the preparation conditions and the amount of starch added to the concentration-induced sodium alginate-calcium ion gel, thereby constructing A coexistence system of sodium alginate gelation and starch gelatinization was developed. The results show that when the mass concentration of sodium alginate solution is 1?g/100?mL and the concentration of calcium ion solution is 3?mmol/L, the evaporation of water caused by heat treatment causes the sodium alginate-calcium ion system to change from the initial solution state ( Storage modulus (G’) G”), and the calcium ion concentration at the critical point of gelation is 5.1?mmol/L. When the starch mass concentration is between 4 and 6?g/100?mL, the mixed system of starch and sodium alginate-calcium ions not only changes from the solution state before water evaporation (¦Ä>45¡ã) to the solution state after water evaporation for 30?min It is in a solid-like state (¦Ä<45¡ã) and has good preparation operability. The starch and sodium alginate-calcium ion sample system prepared under the above ratio conditions showed a tightly connected network structure under a scanning electron microscope after water evaporation, and the G’ value increased and the n value decreased, proving that according to The system prepared with the above concentration can form a coexistence system of sodium alginate gelation and starch gelatinization during the evaporation of water.

Introduction to Sodium Alginate’s Role in Food Science

In recent advancements within the field of food science and rheology, the exploration of the effects of concentration-induced sodium alginate gel on the gelatinization and retrogradation characteristics of rice starch has yielded promising results. Utilizing rheological methods as the principal investigative tool, this study has meticulously determined the optimal preparation conditions and the precise amount of starch necessary for the creation of a concentration-induced sodium alginate-calcium ion gel. This has facilitated the development of a coexistent system where sodium alginate gelation and starch gelatinization occur simultaneously.

Optimizing Gelation Conditions for Sodium Alginate

The study demonstrates that optimal gelation of sodium alginate occurs at a mass concentration of 1g per 100mL in the sodium alginate solution, with the calcium ion solution concentration set at 3mmol/L. The heating process, essential for the treatment, causes water to evaporate, which in turn transitions the sodium alginate-calcium ion system from its initial liquid state to a more solid-like state. This transition is quantified through changes in the storage modulus (G’) and loss modulus (G”), with the critical point of gelation determined to be at a calcium ion concentration of 5.1mmol/L.

Transitional Behavior of Starch in the Sodium Alginate System

Further examination within this study reveals that a starch mass concentration range of 4 to 6g per 100mL, when integrated with the sodium alginate-calcium ions system, not only undergoes a transition from a liquid state pre-water evaporation to a solid-like state post 30 minutes of water evaporation but also exhibits superior preparation operability. This signifies a transformation denoted by a decrease in delta (Δ) below 45 degrees, indicating a solid-like consistency.

The preparation under these specified concentration ratios has been meticulously analyzed under a scanning electron microscope post the water evaporation process. The observations highlighted a tightly interconnected network structure, alongside an increase in the G’ value and a decrease in the n value. These findings incontrovertibly suggest that the system, prepared under the stated conditions, successfully forms a coexistent system of sodium alginate gelation and starch gelatinization during the water evaporation phase.

Microstructural Insights and Rheological Findings

This breakthrough in food science not only enhances our understanding of the rheological properties of food gels but also opens up new avenues for the development of food products with improved texture and stability. The coexistence system of sodium alginate gelation and starch gelatinization, as unveiled by this study, offers a novel approach to modifying the textural properties of food products, potentially leading to the creation of innovative food textures that could meet consumer demands for diverse and high-quality food experiences.

The implications of these findings are vast, offering potential applications in the food industry that could lead to the development of new products with enhanced textural and nutritional properties. Moreover, this research paves the way for future studies to further explore and optimize the gelation and gelatinization processes, potentially unlocking new possibilities in food science and technology.

For futher details of this article and research, feel free to contact our team for assistance.

Original research was done by He Lu, Xiang Zhongqi, Zhou Yanqing, Yang Ying, Zhao Wenjing

About ETprotein:

ETprotein, a reputable plant protein vegan protein Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan protein and plant proteins. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, oat protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, various of plant peptides etc. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to get a free sample of their protein products, please contact them and email sales(at)ETprotein.com today.