Dermohyospora Yeast Produces Microbial Oil Through Fermentation Of Rice Straw Hydrolyzate

Exploring the production of microbial oils from Spartina hydrolyzate through optimized hydrolysis and fermentation, showcasing renewable energy potential from biomass.

This study studied the direct fermentation of the oleaginous yeast Trichosporoncutaneum using the Spartina hydrolyzate that had undergone simple detoxification treatment to produce microbial oils. First, use 1%, 2%, 4% and 6% dilute sulfuric acid to hydrolyze rice straw at 122¡ãC. The rice straw/sulfuric acid (solid/liquid ratio) is 10%. The results showed that the total reducing sugar content was the highest after hydrolysis for 40 minutes at an acid concentration of 6%. When 1% dilute sulfuric acid hydrolyzed rice straw at 140¡ãC, the glucose yield in the hydrolyzate reached a maximum of 14.2g/L after 2.8 hours. Then, the Spartina hydrolyzate under these conditions was freeze-dried and concentrated into different multiples, and used as a fermentation culture medium for the dermatophyte yeast. When the concentration multiple of the hydrolyzate was 4.0, the oil production was up to 6.0g/L. It provides a new way to utilize Spartina efficiently and develop Spartina as an energy plant.

Introduction to Microbial Oil Production from Spartina Hydrolyzate

In the quest for sustainable and renewable energy sources, the study of microbial oils presents a promising avenue. This research focuses on the direct fermentation of the oleaginous yeast Trichosporon cutaneum using Spartina hydrolyzate, treated with a simple detoxification process, to produce microbial oils. The study meticulously explores the hydrolysis of rice straw with dilute sulfuric acid at varying concentrations and its subsequent utilization in the fermentation process to yield significant quantities of microbial oils.

Optimizing Rice Straw Hydrolysis for Maximum Sugar Yield

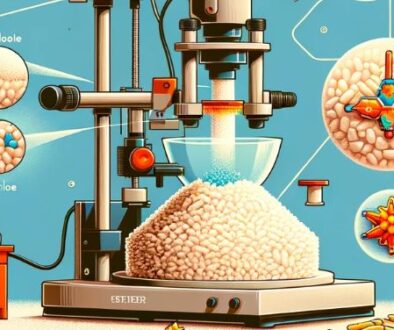

The initial phase of the study involved hydrolyzing rice straw using 1%, 2%, 4%, and 6% dilute sulfuric acid at a temperature of 122°C, maintaining a solid/liquid ratio of 10%. The results indicated a peak in the total reducing sugar content when hydrolyzed for 40 minutes at an acid concentration of 6%. This phase aimed at optimizing the hydrolysis process to ensure the maximum yield of fermentable sugars, crucial for the subsequent fermentation process.

Further experimentation at a higher temperature of 140°C, using 1% dilute sulfuric acid, revealed that the glucose yield in the hydrolyzate peaked at 14.2g/L after 2.8 hours. This significant finding underscores the critical impact of hydrolysis conditions on the availability of fermentable sugars.

Enhanced Glucose Production at Higher Hydrolysis Temperatures

The study then proceeded to utilize the Spartina hydrolyzate, produced under these optimized conditions, as a fermentation culture medium. The hydrolyzate was freeze-dried and concentrated to different multiples to evaluate its efficacy in supporting the growth of Trichosporon cutaneum and the production of microbial oils. Remarkably, when the concentration multiple of the hydrolyzate was set to 4.0, the oil production reached an impressive 6.0g/L. This outcome not only demonstrates the feasibility of using Spartina hydrolyzate as a viable substrate for microbial oil production but also highlights the potential of Trichosporon cutaneum as a robust yeast strain for bio-oil production.

Fermentation Using Concentrated Spartina Hydrolyzate for Oil Production

The study presents a novel approach to biomass utilization, offering insights into the efficient conversion of rice straw into valuable microbial oils through a streamlined process involving hydrolysis and fermentation. The utilization of Spartina, a readily available biomass, further accentuates the ecological and economic advantages of this method. By converting agricultural waste into a valuable resource, this study contributes to the development of sustainable bioenergy solutions.

This research underscores the potential of Spartina as an energy plant and lays the groundwork for further exploration into the use of various biomass types for microbial oil production. The findings offer a promising perspective on the development of renewable energy sources, highlighting the importance of innovative approaches in the quest for sustainability. The study serves as a significant step forward in the field of bioenergy, providing a foundation for future research and development in the utilization of biomass for energy production.

For futher details of this article and research, feel free to contact our team for assistance.

Original research was done by Shen Junjun, Li Fuchao, Yang Qingli, Feng Dawei, Qin Song, Zhao Zongbao

About ETprotein:

ETprotein, a reputable plant protein vegan protein Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan protein and plant proteins. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, oat protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, various of plant peptides etc. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to get a free sample of their protein products, please contact them and email sales(at)ETprotein.com today.