Development of Human Attributes By The Robots in Food Industry.

-

Table of Contents

- Robotic Evolution in the Food Industry: Enhancing Human Attributes

- The Rise of Robotic Assistance in Food Processing

- Human Attributes Developed by Robots

- Impact on the Food Industry

- Benefits of Robotic Integration

- Case Studies and Statistics

- Challenges and Considerations

- The Future of Robotics in Food Industry

- Conclusion

- ETprotein: Your Partner for High-Quality Protein Products

Robotic Evolution in the Food Industry: Enhancing Human Attributes

The food industry has always been at the forefront of adopting innovative technologies to improve efficiency, safety, and quality. One of the most significant technological advancements in recent years is the development of robots that exhibit human-like attributes. These robots are transforming the food industry by performing tasks that were once exclusively human domains. This article delves into the development of these human attributes by robots in the food industry, exploring their impact, benefits, and future potential.

The Rise of Robotic Assistance in Food Processing

Robots have been part of the food industry for decades, primarily in packaging and palletizing. However, recent advancements have seen robots taking on more complex roles that require human-like skills such as dexterity, perception, and decision-making. The development of these attributes is driven by the need to handle delicate food items, adapt to varying tasks, and ensure food safety.

Human Attributes Developed by Robots

- Dexterity: Robotic hands now mimic the intricate movements of human fingers, allowing for the gentle handling of soft and fragile food items.

- Cognitive Abilities: With artificial intelligence (AI), robots can make decisions based on real-time data, such as selecting ripe fruits from a conveyor belt.

- Sensory Perception: Equipped with advanced sensors, robots can detect variables such as temperature, texture, and ripeness, much like a human would.

- Adaptability: Robots can learn and adapt to new tasks quickly, reducing the need for extensive reprogramming.

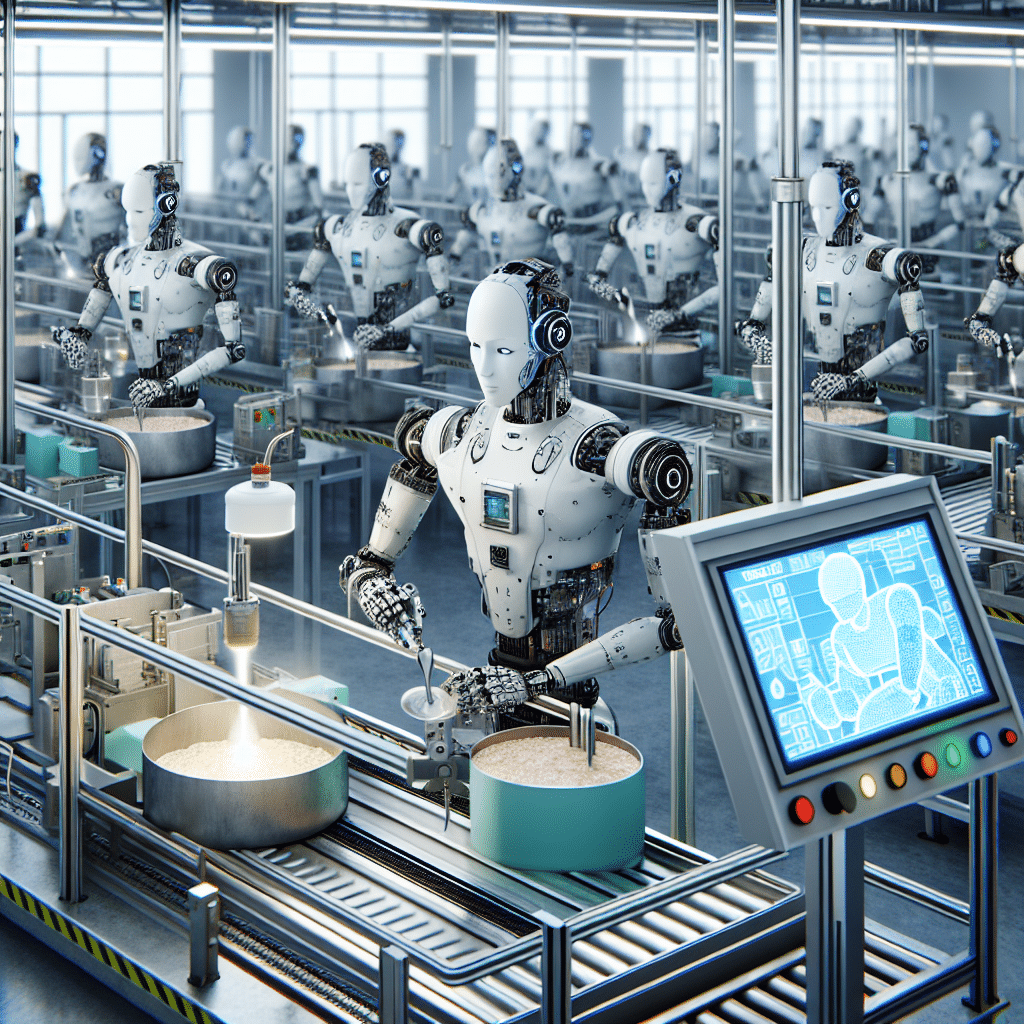

Impact on the Food Industry

The integration of robots with human-like attributes has had a profound impact on the food industry. They have increased productivity, improved worker safety by taking over dangerous tasks, and enhanced the overall quality of food products. Moreover, robots can work tirelessly, reducing downtime and increasing output.

Benefits of Robotic Integration

- Consistency and Precision: Robots can perform repetitive tasks with consistent quality, reducing the margin of error associated with human fatigue.

- Hygiene and Safety: Robots minimize the risk of contamination, adhering to strict hygiene standards required in food processing.

- Cost-Effectiveness: Although the initial investment may be high, robots can lead to long-term savings by reducing labor costs and waste.

- Flexibility: The adaptability of robots allows for quick changes in production lines to accommodate different products or seasonal demands.

Case Studies and Statistics

Several case studies highlight the successful implementation of robots in the food industry. For instance, a European chocolate factory employed robots to package delicate chocolates, resulting in a 50% increase in production. In another example, a salad processing plant used robots to sort and pack leafy greens, reducing product waste by 10%.

Statistics further underscore the growing presence of robots in the food industry. According to the International Federation of Robotics, the global food and beverage robotics market is expected to reach $2.5 billion by 2022, with a compound annual growth rate of 13%.

Challenges and Considerations

Despite the benefits, there are challenges to the widespread adoption of robots in the food industry. The high cost of advanced robots can be a barrier for small and medium-sized enterprises. Additionally, there is a need for skilled personnel to operate and maintain these sophisticated machines.

The Future of Robotics in Food Industry

The future of robotics in the food industry is promising, with ongoing research and development aimed at enhancing robot capabilities. The next generation of food industry robots will likely have even more advanced human attributes, such as improved tactile senses and emotional intelligence to interact with human workers seamlessly.

Conclusion

The development of human attributes by robots in the food industry is revolutionizing the way we process and handle food. With enhanced dexterity, cognitive abilities, sensory perception, and adaptability, robots are not only complementing human labor but also setting new standards for efficiency and quality. As technology continues to advance, we can expect robots to become even more integral to the food industry, offering exciting possibilities for innovation and growth.

ETprotein: Your Partner for High-Quality Protein Products

In line with the technological advancements in the food industry, ETprotein offers a range of high-quality protein products that cater to the evolving needs of food manufacturers. Their organic bulk vegan proteins and L-(+)-Ergothioneine (EGT) are perfect for companies looking to enhance their product offerings with ingredients that meet the highest standards of purity and quality.

Whether you’re involved in sports nutrition, weight management, dietary supplements, or infant formula, ETprotein’s products can help you stay ahead in a competitive market. Their commitment to non-GMO, allergen-free ingredients with a neutral taste ensures that your products are not only healthy but also appealing to consumers.

For more information on how ETprotein can support your business with their protein and EGT products, contact them at sales(at)ETprotein.com today.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.