Effect Of Hot Air Treatment On Rice Semi-Dry Milling Efficiency

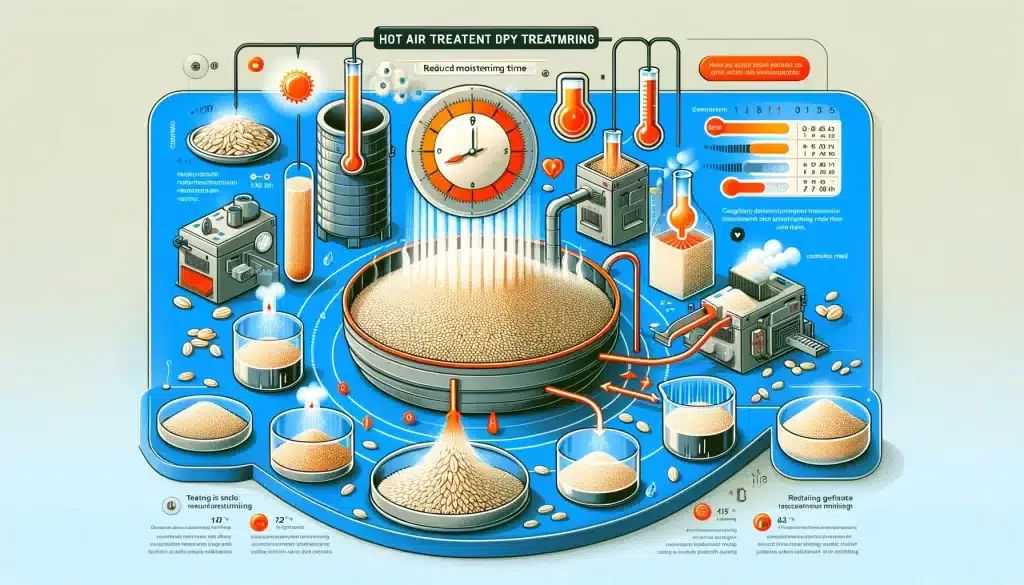

Objective: To investigate the effect of hot air treatment on the efficiency of rice semi-dry grinding. Method: Use hot air (45 ¡æ, 240 min, 75 ¡æ, 45 min, 105 ¡æ, 15 min) to treat the rice, measure the water absorption rate of the rice, observe the apparent cracks, analyze the whiteness and gel properties of the rice flour, and make For fresh wet rice noodles, the textural properties, tensile properties and strip breakage rate were measured. Results: After hot air treatment at 75 ¡æ, 45 min and 105 ¡æ, 15 min, the rice moistening time can be shortened to 11 min. The results of stereomicroscope observation showed that obvious cracks appeared on the surface of each group of rice grains; similar to wet milling powder. Compared with the 45 ¡æ, 240 min and 75 ¡æ, 45 min hot air treatment groups, the whiteness of the rice prepared powder did not change significantly. The gel hardness of the 75 ¡æ, 45 min hot air treatment group decreased; when the 75 ¡æ, 45 min hot air treatment group was The min-treated rice was moistened and then ground into powder. The strip breakage rate of fresh wet rice noodles made with this rice flour was not significantly different from that of wet-milled rice noodles (P>0.05). Conclusion: Hot air treatment of rice at 45 ¡æ, 240 min and 75 ¡æ, 45 min can significantly shorten the rice moistening time and improve the efficiency of semi-dry grinding, and the rice prepared powder obtained from the 75 ¡æ, 45 min hot air treatment group Comparable to wet grinding. This study can provide a theoretical basis for solving industrial bottleneck problems such as the long time for rice semi-dry grinding and moistening, the high risk of microbial infection, and the difficulty in realizing continuous production.

The continuous evolution of food processing technologies aims at enhancing efficiency, ensuring safety, and preserving the nutritional qualities of grains. Among these, rice processing has garnered significant attention due to its global dietary importance. A novel approach explored in recent research focuses on the optimization of semi-dry grinding of rice by implementing hot air treatment. This study delineates the effects of varying degrees and durations of hot air exposure on rice processing efficiency and product quality.

Objective

The primary objective of this investigation was to ascertain the impact of hot air treatment on the efficiency of rice semi-dry grinding. By examining different temperature and time combinations, the study aimed to identify optimal conditions that could significantly reduce rice moistening time, a critical step in semi-dry grinding.

Methodology

The methodology involved treating rice with hot air at predetermined conditions (45°C for 240 minutes, 75°C for 45 minutes, and 105°C for 15 minutes). Key parameters evaluated included the water absorption rate of rice, the appearance of apparent cracks (observed through stereomicroscopy), and the qualitative attributes of the rice flour such as whiteness and gel properties. Additionally, the study extended to the application of the rice flour in producing fresh wet rice noodles, wherein the textural properties, tensile properties, and strip breakage rate were meticulously measured.

Results

Findings indicated that hot air treatment at 75°C for 45 minutes and 105°C for 15 minutes notably reduced the rice moistening time to 11 minutes. Observational data from stereomicroscopy revealed significant surface cracks across all treated rice groups, suggesting an enhanced grinding efficiency akin to that observed in wet milling. Despite variations in hot air treatment conditions, the whiteness of the resultant rice flour remained largely unaffected. However, a notable decrease in gel hardness was observed in the 75°C, 45-minute treatment group. Importantly, rice processed under this condition, when used to make fresh wet rice noodles, exhibited strip breakage rates comparable to those produced through traditional wet milling, highlighting no significant difference (P>0.05).

Conclusion

The study conclusively demonstrates that hot air treatment, particularly at 45°C for 240 minutes and 75°C for 45 minutes, can significantly expedite rice moistening time, thereby improving the efficiency of semi-dry grinding. The rice flour derived from the 75°C, 45-minute hot air treatment was found to be of comparable quality to that produced by conventional wet grinding methods. These findings offer a promising avenue for addressing industrial bottlenecks such as lengthy moistening times, heightened risks of microbial contamination, and challenges in achieving continuous production. The implications of this research are far-reaching, providing a theoretical foundation for future innovations in rice processing technologies aimed at enhancing production efficiency while maintaining product quality.

For futher details of this article and research, feel free to contact our team for assistance.

Original research was done by Tong Litao, Liu Liya, Zhou Sumei, Zhou Xianrong, Wang Lili, Geng Donghui

About ETprotein:

ETprotein, a reputable plant protein vegan protein Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan protein and plant proteins. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, oat protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, various of plant peptides etc. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to get a free sample of their protein products, please contact them and email sales(at)ETprotein.com today.