Embracing Eco-Friendly Practices in Equipment Manufacturing

-

Table of Contents

- Eco-Friendly Equipment Manufacturing: Practices for a Sustainable Future

- The Imperative for Sustainable Manufacturing

- Strategies for Eco-Friendly Equipment Manufacturing

- Renewable Energy and Efficiency

- Sustainable Materials and Design

- Waste Reduction and Emissions Control

- Green Technology and Innovation

- Benefits of Eco-Friendly Manufacturing

- Case Studies and Statistics

- Challenges and Future Outlook

- Conclusion: Embracing a Greener Manufacturing Paradigm

- Discover ETprotein’s Eco-Conscious Protein Products

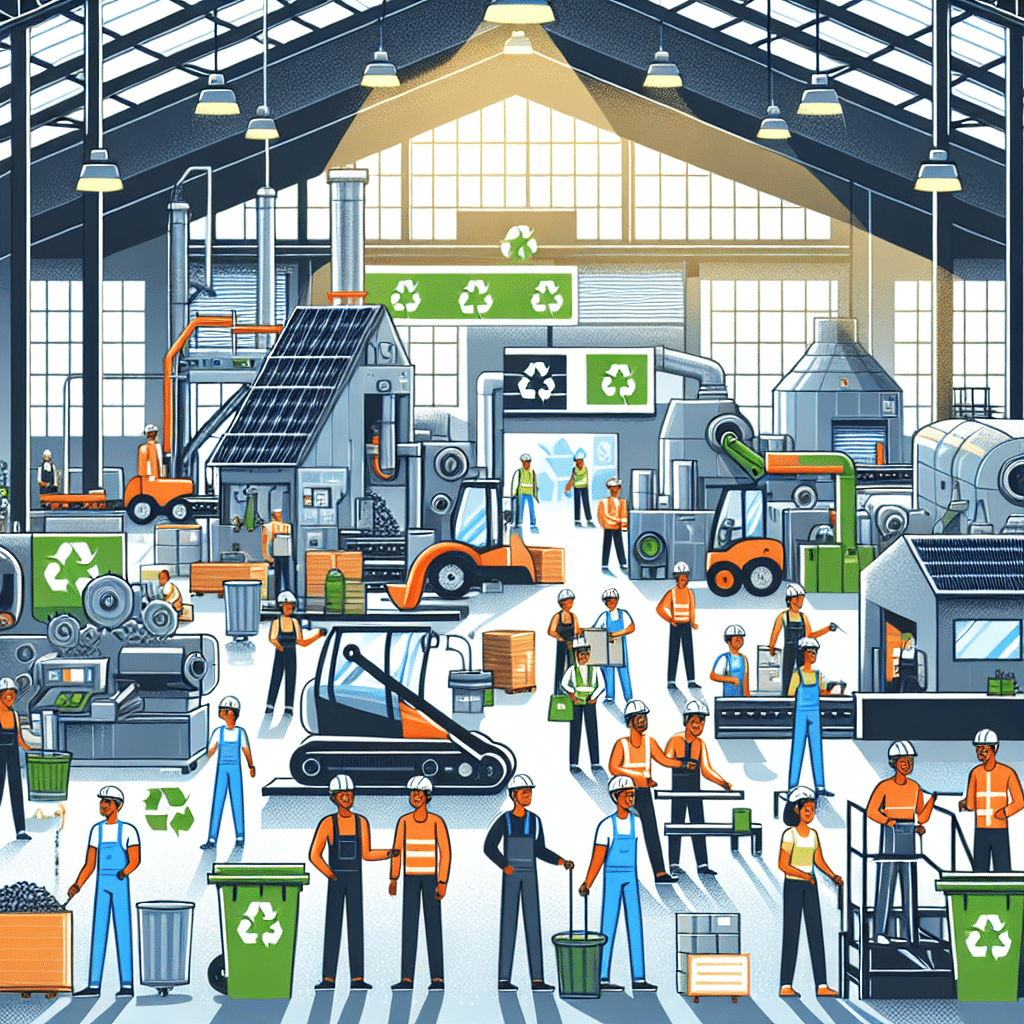

Eco-Friendly Equipment Manufacturing: Practices for a Sustainable Future

In an era where environmental concerns are at the forefront of global discourse, industries across the board are re-evaluating their practices to align with eco-friendly standards. The equipment manufacturing sector, known for its significant environmental footprint, is no exception. As the demand for sustainable products and practices grows, manufacturers are embracing innovative strategies to reduce waste, conserve resources, and minimize pollution. This article delves into the transformative eco-friendly practices being adopted within the equipment manufacturing industry and the benefits they offer to businesses, consumers, and the planet.

The Imperative for Sustainable Manufacturing

The manufacturing sector has traditionally been resource-intensive, contributing to environmental degradation through high energy consumption, waste generation, and greenhouse gas emissions. However, with the increasing awareness of climate change and its impacts, there is a pressing need for manufacturers to transition towards more sustainable operations. This shift not only addresses environmental concerns but also meets the evolving preferences of consumers who are more inclined to support eco-conscious brands.

Strategies for Eco-Friendly Equipment Manufacturing

Manufacturers are implementing a variety of strategies to make their operations more sustainable. These include:

- Adopting renewable energy sources

- Improving energy efficiency

- Utilizing sustainable materials

- Enhancing product design for longevity and recyclability

- Implementing waste reduction techniques

- Adhering to stricter emissions standards

- Investing in green technology and innovation

Renewable Energy and Efficiency

One of the most impactful changes in the manufacturing industry is the shift towards renewable energy sources such as solar, wind, and hydroelectric power. By reducing reliance on fossil fuels, manufacturers can significantly lower their carbon footprint. Additionally, improving energy efficiency in production processes and facility operations can lead to substantial reductions in energy consumption and costs.

Sustainable Materials and Design

The choice of materials plays a crucial role in sustainable manufacturing. By opting for recycled, biodegradable, or sustainably sourced materials, manufacturers can decrease the environmental impact of their products. Moreover, designing equipment with longevity and end-of-life recyclability in mind ensures that products can be reused or repurposed, thereby reducing waste.

Waste Reduction and Emissions Control

Manufacturers are also focusing on minimizing waste through lean manufacturing techniques and closed-loop systems that recycle scrap materials back into production. Stricter emissions standards are being adopted to limit the release of pollutants, contributing to cleaner air and a healthier environment.

Green Technology and Innovation

Investment in green technology is essential for developing new methods and equipment that are less harmful to the environment. Innovations such as 3D printing, advanced robotics, and AI-driven optimization can lead to more efficient production processes with a smaller ecological footprint.

Benefits of Eco-Friendly Manufacturing

The adoption of sustainable practices in equipment manufacturing offers numerous benefits:

- Reduced environmental impact

- Cost savings from energy efficiency and waste reduction

- Enhanced brand reputation and consumer trust

- Compliance with environmental regulations and standards

- Creation of new market opportunities for green products

Case Studies and Statistics

Several leading manufacturers have already seen positive outcomes from implementing eco-friendly practices. For instance, a report by the Environmental Protection Agency (EPA) highlighted that by optimizing energy use, a manufacturing plant could reduce its energy consumption by up to 30%. Another study found that companies that invested in sustainable materials and supply chains experienced a 5-20% increase in sales due to consumer preference for eco-friendly products.

Challenges and Future Outlook

While the shift towards sustainability is promising, manufacturers face challenges such as the initial cost of green technology and the need for skilled workers to manage new systems. However, with continued innovation and support from governments and consumers, the future of eco-friendly equipment manufacturing looks bright.

Conclusion: Embracing a Greener Manufacturing Paradigm

The equipment manufacturing industry is at a pivotal point in its evolution, with sustainability becoming a core component of its operations. By embracing eco-friendly practices, manufacturers can not only contribute to a healthier planet but also enjoy economic benefits and a competitive edge in the market. The key takeaways for the industry are clear: invest in renewable energy, prioritize efficiency, choose sustainable materials, design with the environment in mind, reduce waste, control emissions, and innovate for a greener future.

Discover ETprotein’s Eco-Conscious Protein Products

In line with sustainable practices, ETprotein offers a range of organic bulk vegan proteins and L-(+)-Ergothioneine that cater to various industries while maintaining a commitment to environmental responsibility. Their products, characterized by high purity and allergen-free attributes, are an excellent choice for businesses looking to incorporate eco-friendly ingredients into their offerings.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.