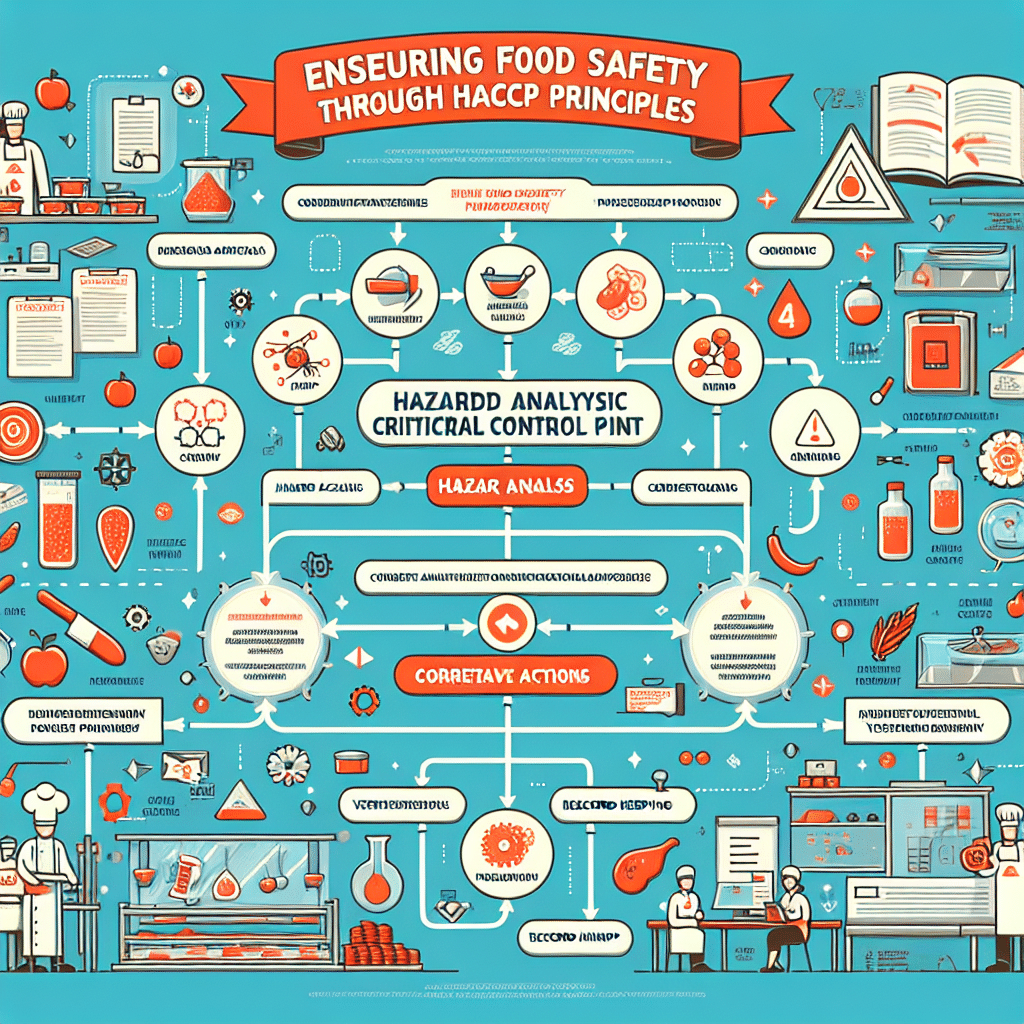

Ensuring Food Safety through HACCP Principles

-

Table of Contents

- HACCP Principles: The Backbone of Food Safety Assurance

- Understanding HACCP and Its Importance

- The Seven Core Principles of HACCP

- Conducting a Hazard Analysis

- Determining Critical Control Points

- Establishing Critical Limits

- Establishing Monitoring Procedures

- Establishing Corrective Actions

- Establishing Verification Procedures

- Establishing Record-Keeping and Documentation Procedures

- Global Impact and Statistics

- Conclusion: The Role of HACCP in Food Safety

- ETprotein: Your Partner for Safe and High-Quality Protein Products

HACCP Principles: The Backbone of Food Safety Assurance

Food safety is a critical concern for consumers, producers, and regulators worldwide. With the increasing complexity of food supply chains, ensuring the safety of food products has become more challenging. The Hazard Analysis and Critical Control Points (HACCP) system is a systematic preventive approach to food safety that identifies, evaluates, and controls hazards which are significant for food safety. This article delves into the principles of HACCP and how they are applied to ensure food safety.

Understanding HACCP and Its Importance

HACCP is a management system that addresses food safety through the analysis and control of biological, chemical, and physical hazards from raw material production, procurement, and handling, to manufacturing, distribution, and consumption of the finished product. The importance of HACCP lies in its proactive nature, preventing food safety issues before they occur rather than inspecting finished products for the effects of hazards.

The Seven Core Principles of HACCP

The HACCP system is built on seven core principles that provide a framework for its implementation. These principles are universally recognized and accepted as essential for food safety.

- Conduct a hazard analysis

- Determine the Critical Control Points (CCPs)

- Establish critical limits

- Establish monitoring procedures

- Establish corrective actions

- Establish verification procedures

- Establish record-keeping and documentation procedures

Conducting a Hazard Analysis

The first step in HACCP is to conduct a thorough hazard analysis. This involves identifying potential hazards that could affect food safety and determining the measures necessary to control those hazards. Hazards can be of various types, including biological (e.g., bacteria, viruses), chemical (e.g., toxins, allergens), and physical (e.g., glass, metal shards).

Determining Critical Control Points

Once hazards have been identified, the next step is to determine the points in the process where these hazards can be effectively controlled. These points are known as Critical Control Points (CCPs). Not every step in a food process is a CCP; identifying these points requires a deep understanding of the process flow and hazard control.

Establishing Critical Limits

For each CCP, there must be one or more measurable parameters that can be controlled. These are known as critical limits and could include temperature, pH, time, or other scientific measurements that can prevent, eliminate, or reduce a food safety hazard to an acceptable level.

Establishing Monitoring Procedures

Effective monitoring of CCPs is essential to ensure that each CCP stays within its critical limits. Monitoring procedures must be established to include measurements or observations that can be conducted in a timely manner to provide this assurance.

Establishing Corrective Actions

When monitoring indicates that a CCP is not within the established critical limits, corrective actions must be taken. These actions should aim to identify the cause of the problem and eliminate it, ensuring that no unsafe product is released.

Establishing Verification Procedures

Verification procedures are necessary to confirm that the HACCP system is working effectively. This may include additional testing, validation of critical limits, and review of monitoring and corrective action records.

Establishing Record-Keeping and Documentation Procedures

Keeping detailed records is an integral part of HACCP. Documentation provides evidence that the HACCP system is functioning correctly and is essential for tracing in the event of a food safety issue.

Global Impact and Statistics

The implementation of HACCP has had a significant impact on food safety around the globe. According to the World Health Organization (WHO), an estimated 600 million – almost 1 in 10 people in the world – fall ill after eating contaminated food, and 420,000 die every year. HACCP and similar food safety systems are crucial in reducing these numbers.

Conclusion: The Role of HACCP in Food Safety

HACCP is a cornerstone of modern food safety practices. By following its principles, food producers can significantly reduce the risk of contamination and ensure that their products are safe for consumption. The systematic approach of HACCP not only protects public health but also enhances the quality and consistency of food products, thereby supporting consumer confidence and industry growth.

ETprotein: Your Partner for Safe and High-Quality Protein Products

Ensuring the safety and quality of protein products is paramount for manufacturers and suppliers. ETprotein company’s protein products adhere to stringent safety standards, including HACCP principles, to ensure that their offerings are of the highest quality. Their range of organic bulk vegan proteins and L-(+)-Ergothioneine (EGT) products are non-GMO, allergen-free, and boast a high purity level, making them ideal for various industries.

Whether you are in the nutraceutical, pharmaceutical, cosmeceutical, veterinary, or food and beverage industry, ETprotein can meet your protein needs with their extensive product range. By choosing ETprotein, you are partnering with a company that is trusted by leading global brands and committed to excellence in food safety and quality.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.