Evolution Of Food Automation

Table of Contents

- Food Automation Evolution: Revolutionizing the Culinary Landscape

- The Roots of Food Automation

- Modern Food Automation: A Technological Renaissance

- Automation in Agriculture: Feeding the Future

- Automation in Food Processing and Packaging

- Automation in Food Service: The Rise of Robotic Restaurants

- Challenges and Considerations

- The Future of Food Automation

- Conclusion

- Discover ETprotein’s High-Quality Protein Products

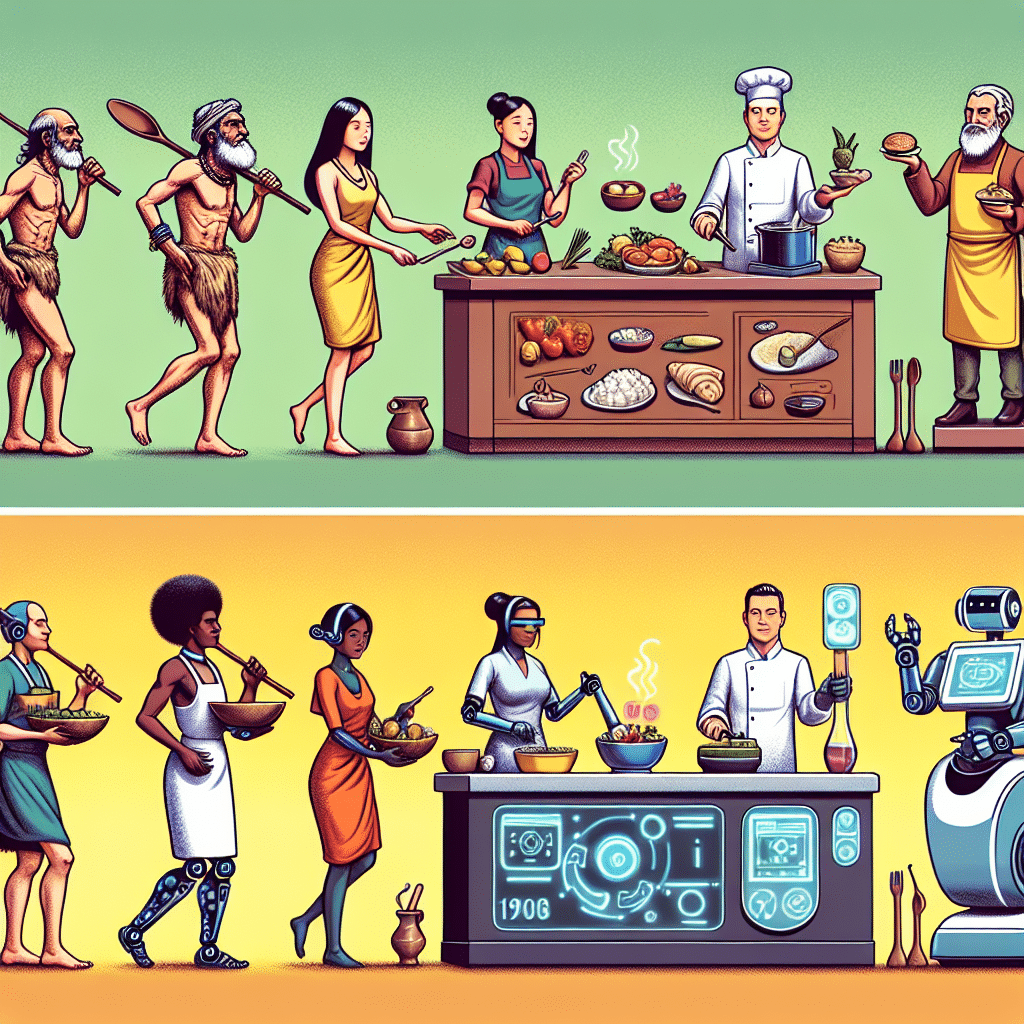

Food Automation Evolution: Revolutionizing the Culinary Landscape

The evolution of food automation has been a transformative journey, reshaping the way we produce, process, and serve food. From the early days of mechanized agriculture to the sophisticated robotics and AI-driven systems of today, the food industry has witnessed a revolution that has not only increased efficiency but also redefined the culinary experience. This article delves into the history, current trends, and future prospects of food automation, offering valuable insights into this dynamic field.

The Roots of Food Automation

The seeds of food automation were sown with the advent of the Industrial Revolution, which introduced basic machinery to aid in food production. However, it wasn’t until the 20th century that we saw significant strides in food technology:

- The invention of canned food and pasteurization in the 19th century paved the way for food preservation.

- Conveyor belts and assembly lines, first popularized by the automotive industry, were adapted for food packaging and processing.

- The mid-1900s saw the rise of fast food and the development of appliances like microwaves, which revolutionized food preparation.

Modern Food Automation: A Technological Renaissance

Today’s food automation systems are characterized by their use of cutting-edge technology:

- Robotics: Robotic arms and machines are now commonplace in food manufacturing, handling tasks from packaging to intricate food decoration.

- Artificial Intelligence (AI) and Machine Learning (ML): AI algorithms optimize supply chains, predict maintenance needs, and personalize consumer experiences.

- Internet of Things (IoT): IoT devices track food safety, monitor storage conditions, and streamline operations.

Statistics show that the global food automation industry is expected to grow significantly. According to a report by Meticulous Research, the food automation market is projected to reach $29.4 billion by 2027, growing at a CAGR of 9.5% from 2020.

Automation in Agriculture: Feeding the Future

Agriculture has seen a significant transformation with the introduction of automated technologies:

- Automated tractors and drones are used for planting, spraying, and monitoring crops.

- Automated irrigation systems conserve water and ensure precise watering schedules.

- Harvesting robots can pick fruits and vegetables, reducing labor costs and increasing efficiency.

These advancements have led to the concept of precision agriculture, where resources are used more efficiently, and crop yields are maximized through data-driven decisions.

Automation in Food Processing and Packaging

Food processing and packaging have been revolutionized by automation:

- Automated sorting systems use sensors and cameras to sort food based on size, color, and ripeness.

- High-speed packaging machines can wrap, label, and seal products faster than ever before.

- 3D food printing offers the potential for customized nutrition and intricate food designs.

These innovations not only enhance productivity but also improve food safety by minimizing human contact with food products.

Automation in Food Service: The Rise of Robotic Restaurants

The food service industry is also embracing automation:

- Robotic chefs and bartenders can prepare meals and mix drinks with precision and consistency.

- Self-service kiosks and mobile apps allow for efficient order taking and payment processing.

- Automated delivery systems, including drones and autonomous vehicles, are being tested for food delivery.

These changes are transforming the dining experience, offering convenience and novelty to consumers.

Challenges and Considerations

Despite the benefits, food automation presents challenges:

- Job displacement due to automation is a concern, necessitating workforce retraining and education.

- Initial costs of automation technology can be high, potentially limiting access for small businesses.

- Technical issues and breakdowns can disrupt production, requiring skilled maintenance personnel.

Addressing these challenges is crucial for the sustainable integration of automation in the food industry.

The Future of Food Automation

The future of food automation is poised for further growth, with trends such as:

- Advanced AI and ML algorithms for even more personalized food experiences.

- Greater integration of sustainable practices within automated systems.

- Continued development of lab-grown meat and plant-based alternatives using automated processes.

As technology continues to evolve, we can expect food automation to become even more sophisticated, shaping the way we think about food production and consumption.

Conclusion

The evolution of food automation has been a journey of innovation and adaptation. From its humble beginnings to the high-tech solutions of today, automation has fundamentally altered the food industry. It has increased efficiency, improved safety, and created new opportunities for businesses and consumers alike. As we look to the future, it is clear that food automation will continue to play a pivotal role in meeting the demands of a growing population and the challenges of a changing world.

Discover ETprotein’s High-Quality Protein Products

In line with the advancements in food automation, ETprotein company’s protein products stand out as a testament to innovation in food ingredients. Their extensive range of organic bulk vegan proteins and L-(+)-Ergothioneine (EGT) products cater to the evolving needs of the food and beverage industry. With a focus on non-GMO, allergen-free, and high-purity ingredients, ETprotein is at the forefront of providing sustainable and health-conscious solutions for manufacturers and consumers alike.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.