Foodservice Coatings: Taste and Texture’s Key Role

-

Table of Contents

- Foodservice Coatings: Enhancing Taste and Texture for Culinary Success

- The Importance of Coatings in Foodservice

- Types of Foodservice Coatings

- Case Studies and Statistics: Coatings in Action

- Technological Advancements in Coating Applications

- Challenges and Considerations in Coating Development

- Conclusion: The Future of Foodservice Coatings

- ETprotein: Elevating Foodservice Coatings with High-Quality Protein Products

Foodservice Coatings: Enhancing Taste and Texture for Culinary Success

The foodservice industry is a dynamic and ever-evolving sector where taste and texture play pivotal roles in customer satisfaction and culinary innovation. Foodservice coatings, in particular, are essential in creating the perfect balance between flavor and mouthfeel, making them a critical component in the success of any food product. In this article, we will delve into the importance of coatings in the foodservice industry, explore various types of coatings, and examine how they contribute to the overall sensory experience of food.

The Importance of Coatings in Foodservice

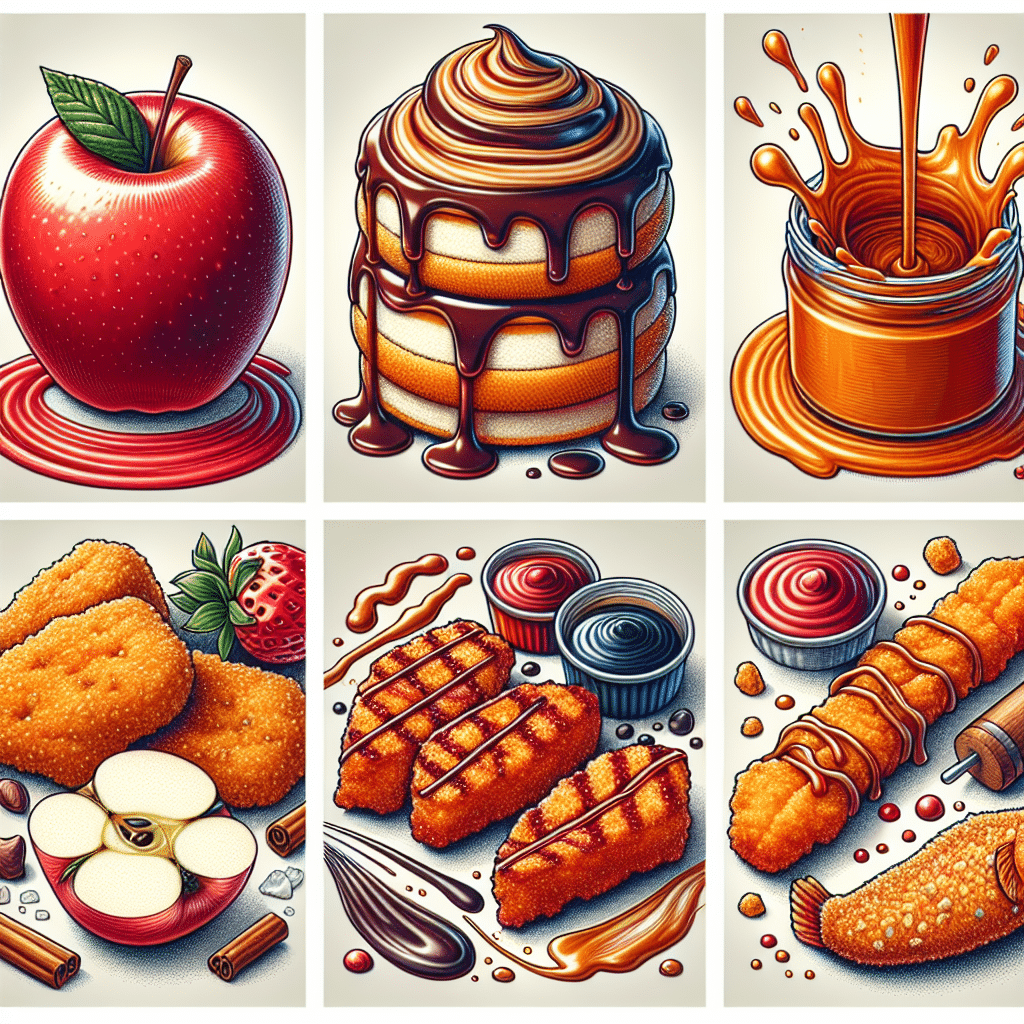

Coatings are applied to a wide range of food products to enhance their appeal, protect their integrity, and add distinctive flavors and textures. From the crispy crust of fried chicken to the smooth glaze on a donut, coatings are integral to the food we love. They serve several purposes:

- Improving visual appeal with a glossy or textured finish

- Adding layers of flavor, either complementary or contrasting

- Creating a barrier to moisture and fat, maintaining product freshness

- Enhancing texture, providing crunchiness, or a smooth mouthfeel

Types of Foodservice Coatings

There are various types of coatings used in the foodservice industry, each with its unique properties and applications:

- Batters and Breading: These coatings are often used for fried foods, providing a crispy texture and golden appearance.

- Glazes and Icings: Typically sweet, these coatings add shine and flavor to baked goods and desserts.

- Sauces and Marinades: These liquid coatings infuse food with flavor and can tenderize meats.

- Edible Films and Laminates: These thin layers serve as protective barriers for food, extending shelf life and maintaining quality.

Case Studies and Statistics: Coatings in Action

Let’s look at some real-world examples and statistics that highlight the impact of coatings in the foodservice industry:

- A study on the effect of batter viscosity on the quality of fried foods showed that a well-formulated batter could reduce oil uptake by up to 40%, resulting in a healthier and more appealing product.

- Consumer research indicates that texture is as important as flavor, with 70% of consumers stating that an interesting texture makes them more likely to buy a product.

- Market analysis reveals that the global food coating ingredients market is expected to grow significantly, driven by consumer demand for convenience foods with enhanced sensory attributes.

Technological Advancements in Coating Applications

Technological advancements have revolutionized the application of coatings in the foodservice industry. Innovations such as airbrushing, enrobing, and electrostatic coating have allowed for more precise and uniform application, resulting in better product consistency and quality. Additionally, the development of new ingredients and formulations has led to coatings that are not only tastier and more texturally appealing but also healthier and more sustainable.

Challenges and Considerations in Coating Development

Developing the perfect coating is not without its challenges. Foodservice providers must consider factors such as:

- Ingredient interactions and stability

- Coating adhesion and integrity during cooking and storage

- Health and nutrition concerns, such as reducing fat and sugar content

- Consumer dietary restrictions and allergen-free options

- Environmental impact and sustainability of coating ingredients

Addressing these challenges requires ongoing research and innovation to create coatings that meet the high standards of the foodservice industry and the expectations of consumers.

Conclusion: The Future of Foodservice Coatings

In conclusion, foodservice coatings are a vital component in the culinary world, significantly influencing the taste and texture of food products. As the industry continues to evolve, we can expect to see more innovative and health-conscious coatings that cater to the diverse preferences of consumers. The key takeaways from this article emphasize the importance of coatings in enhancing the sensory experience of food, the variety of coatings available, and the technological advancements that are shaping the future of foodservice coatings.

ETprotein: Elevating Foodservice Coatings with High-Quality Protein Products

For foodservice professionals looking to enhance their coatings with high-quality protein products, ETprotein offers a range of solutions. Their organic bulk vegan proteins, including rice, pea, and various seed proteins, provide a neutral taste and non-GMO, allergen-free attributes that are perfect for creating innovative coatings that cater to health-conscious consumers. With L-(+)-Ergothioneine purity over 98%, ETprotein’s products are ideal for adding nutritional value to foodservice coatings without compromising on taste or texture.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.