How Are Peanuts Processed: From Field to Snack

-

Table of Contents

- Peanut Processing: From Field to Snack Bowl

- The Cultivation of Peanuts

- Harvesting and Drying

- Shelling and Cleaning

- Grading and Sorting

- Roasting

- Seasoning and Coating

- Packaging

- Quality Control and Safety

- Conclusion: The Journey from Field to Snack Bowl

- Discover ETprotein’s High-Quality Peanut Protein Products

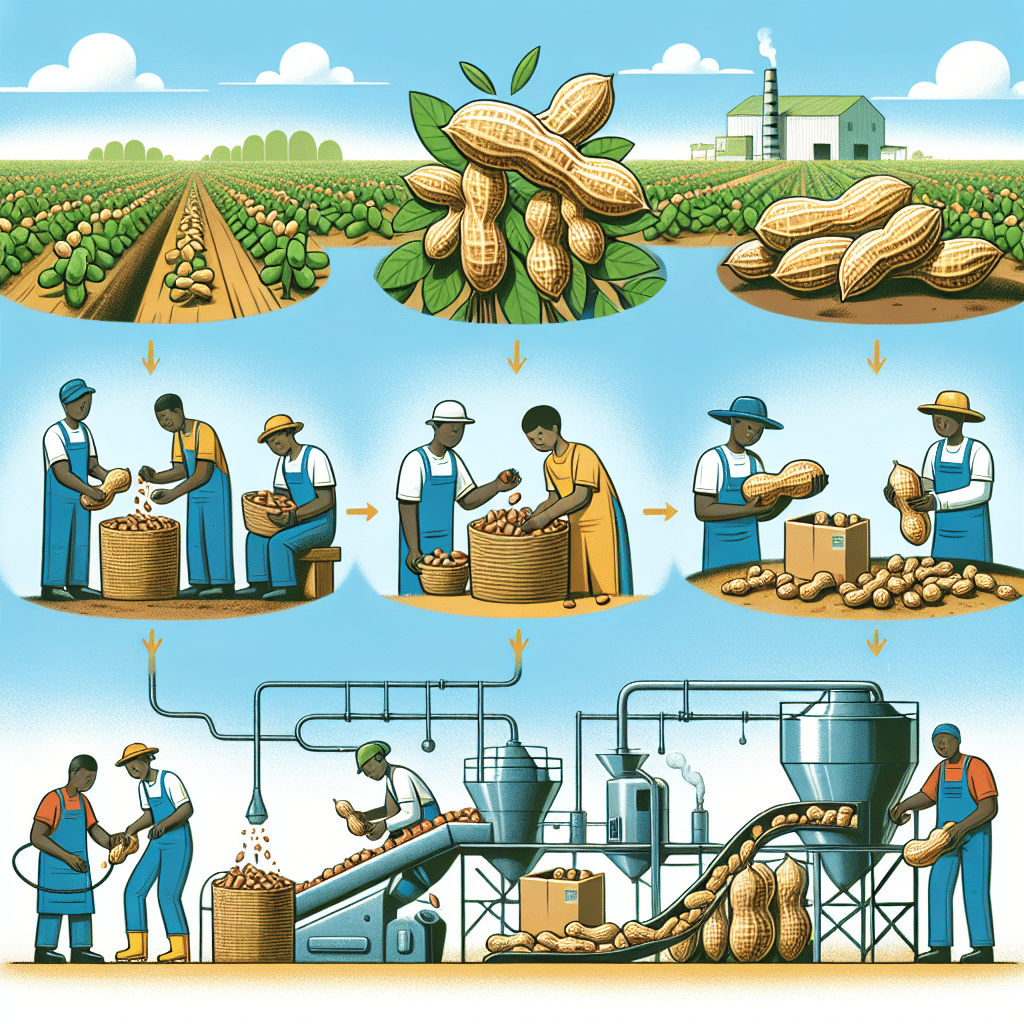

Peanut Processing: From Field to Snack Bowl

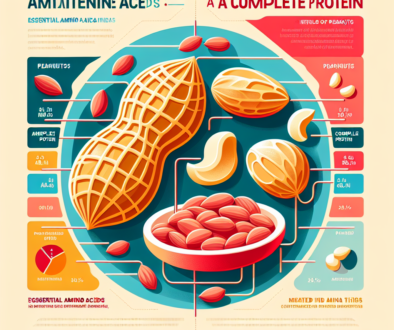

Peanuts, also known as groundnuts, are not only a popular snack but also a versatile ingredient used in various cuisines worldwide. Despite their name, peanuts are not true nuts but legumes, related to beans and lentils. The journey of peanuts from being a humble legume to becoming a crunchy, delightful snack involves a series of intricate steps. This article delves into the fascinating process of peanut processing, shedding light on how these legumes are transformed into the snacks we all love.

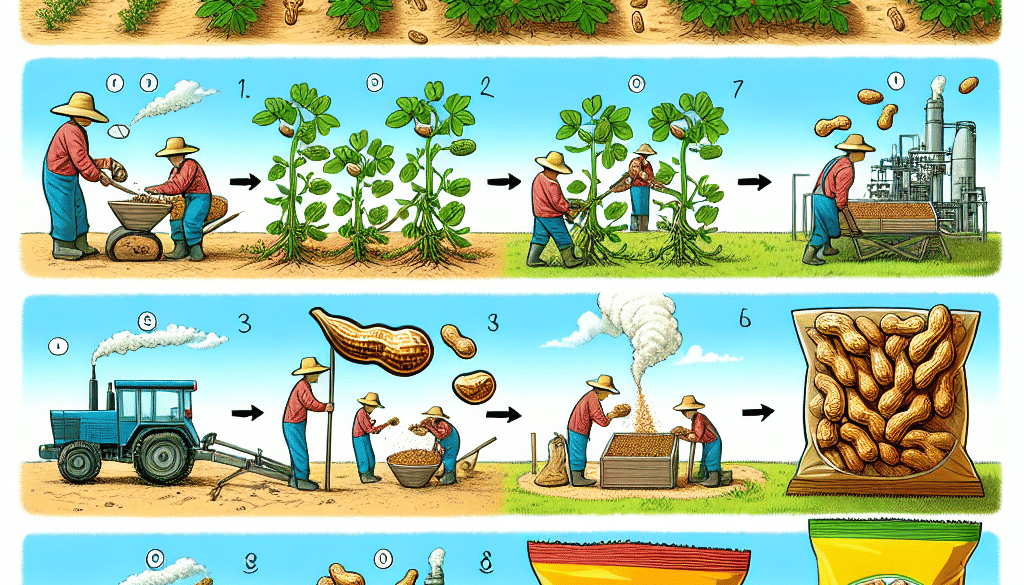

The Cultivation of Peanuts

The peanut processing journey begins in the field. Peanuts are grown in warm climates and require about four to five months of frost-free days to reach harvest. They start as flowers that, after pollination, wilt and grow towards the ground, where the peanut pods develop and mature underground. This unique feature earns them the name “groundnut.”

Harvesting and Drying

Once the peanuts are ready for harvest, farmers use specialized equipment to dig them out of the ground. The plants are then inverted and left in the field to dry for several days. This drying process is crucial as it reduces the moisture content of the peanuts, which is essential for storage and further processing.

Shelling and Cleaning

After drying, peanuts are transported to shelling facilities. Here, machines remove the shells, and the peanuts are separated by size. The shelling process is gentle to prevent damage to the kernels. Once shelled, the peanuts are cleaned to remove any remaining dirt, debris, or imperfect nuts.

Grading and Sorting

Following cleaning, peanuts are graded and sorted based on size, shape, and quality. This step is vital for determining the peanuts’ end use, whether for direct consumption, oil production, or as an ingredient in food products. High-quality peanuts proceed to the next stage of processing, while those with imperfections may be redirected for oil extraction or animal feed.

Roasting

One of the most critical steps in peanut processing is roasting. Roasting not only enhances the flavor but also extends the shelf life of peanuts. There are two primary methods of roasting: dry roasting and oil roasting. Dry roasting involves heating peanuts in an oven without any added oil, while oil roasting submerges the peanuts in hot oil. The method chosen depends on the desired flavor profile and texture.

Seasoning and Coating

After roasting, peanuts can be seasoned or coated with various flavors and ingredients. Seasonings can range from simple salt to a mix of exotic spices. Some peanuts are coated with sweet substances like honey or chocolate, expanding their appeal to different consumer tastes.

Packaging

The final step in the peanut processing chain is packaging. Packaging is designed to protect the peanuts from contamination and preserve their freshness. Vacuum-sealed bags, jars, and resealable pouches are common packaging options that also make it convenient for consumers to enjoy peanuts as a snack.

Quality Control and Safety

Throughout the entire peanut processing journey, quality control and safety are paramount. Facilities adhere to strict food safety standards to prevent contamination, particularly with aflatoxins, which are toxic substances produced by certain molds. Regular testing and monitoring ensure that the final peanut products are safe for consumption.

Conclusion: The Journey from Field to Snack Bowl

The transformation of peanuts from field to snack bowl is a complex process that involves careful attention to detail at every step. From the initial cultivation to the final packaging, each phase is designed to ensure that the peanuts are of the highest quality and safety. The result is a versatile and delicious snack enjoyed by people around the world.

Discover ETprotein’s High-Quality Peanut Protein Products

If you’re interested in incorporating peanut protein into your diet or products, ETprotein offers a range of high-quality peanut protein options. Their peanut protein is perfect for those looking for a plant-based protein source with a neutral taste and non-GMO, allergen-free attributes. ETprotein caters to various industries, including food and beverage, sports nutrition, and health and wellness, providing comprehensive protein solutions for all needs.

About ETprotein:

ETprotein, a reputable protein Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan protein and plant proteins. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein etc. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.