How Can Automation Help Confectionary Companies?

-

Table of Contents

- Automation Advantages for Confectionery Companies: Boosting Efficiency and Sweetening Profits

- The Sweet Spot of Automation in Confectionery Manufacturing

- Enhancing Productivity and Reducing Costs

- Consistency and Quality Assurance

- Adapting to Market Demands with Flexibility and Scalability

- Improving Workplace Safety and Compliance

- Case Studies and Statistics: Sweet Success Stories

- Conclusion: Embracing the Future of Confectionery Production

- ETprotein: Enhancing Confectionery with High-Quality Protein Products

Automation Advantages for Confectionery Companies: Boosting Efficiency and Sweetening Profits

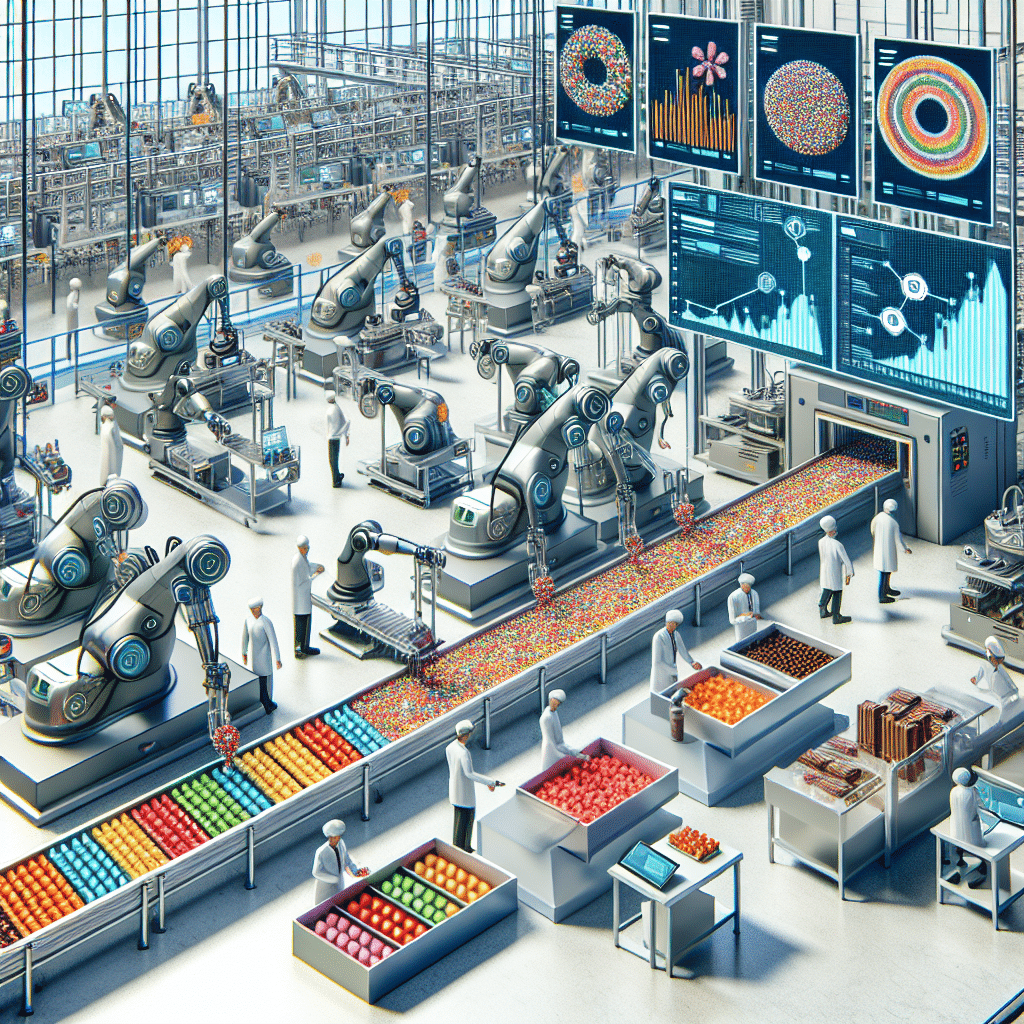

The confectionery industry, known for its sweet treats and delights, is a competitive and ever-evolving sector. With the increasing demand for high-quality products and the need for cost-effective production methods, confectionery companies are turning to automation as a solution. Automation in the confectionery industry can lead to significant improvements in efficiency, consistency, and safety, ultimately enhancing profitability and customer satisfaction.

The Sweet Spot of Automation in Confectionery Manufacturing

Automation technology has revolutionized the way confectionery products are manufactured. From mixing and shaping to packaging and distribution, every step of the production process can benefit from automation. Here are some key areas where automation can make a substantial impact:

- Ingredient Handling and Mixing: Automated systems can precisely measure and mix ingredients, ensuring consistent flavor and quality in every batch.

- Molding and Shaping: Machines can quickly and accurately shape candies, chocolates, and other confections, maintaining uniformity and reducing waste.

- Coating and Decorating: Automated equipment can apply coatings, such as chocolate or glaze, evenly and efficiently, while also handling intricate decorating tasks.

- Packaging: High-speed packaging lines can wrap, seal, and label products faster than manual methods, while also adapting to various packaging designs and sizes.

- Quality Control: Automation includes advanced inspection systems that can detect imperfections or contaminants, ensuring only the best products reach consumers.

Enhancing Productivity and Reducing Costs

One of the primary benefits of automation is the significant increase in productivity it brings. Automated systems can operate continuously without fatigue, leading to higher output rates. Moreover, automation reduces the reliance on manual labor, which can be a major cost in the confectionery industry. By streamlining processes and minimizing human error, companies can achieve a more efficient production line with less waste and lower operational costs.

Consistency and Quality Assurance

Confectionery consumers expect a consistent product, whether it’s the taste, texture, or appearance. Automation ensures that each item produced meets the same high standards. With precise control over the production process, automated systems can replicate the exact conditions required for each product, resulting in uniform quality that customers can trust.

Adapting to Market Demands with Flexibility and Scalability

The confectionery market is dynamic, with seasonal peaks and evolving consumer preferences. Automated systems offer the flexibility to quickly change production lines to accommodate new products or packaging designs. Additionally, automation allows for scalability, enabling companies to increase production volumes to meet market demands without compromising quality or efficiency.

Improving Workplace Safety and Compliance

Confectionery manufacturing involves processes that can be hazardous to workers, such as handling hot ingredients or operating heavy machinery. Automation reduces the need for direct human interaction with dangerous equipment, thereby enhancing workplace safety. Furthermore, automated systems help ensure compliance with food safety regulations by providing traceability and maintaining hygienic production environments.

Case Studies and Statistics: Sweet Success Stories

Several confectionery companies have already experienced the benefits of automation. For instance, a leading chocolate manufacturer reported a 15% increase in production efficiency after implementing automated systems. Another candy company saw a 20% reduction in labor costs while maintaining consistent product quality. These success stories highlight the tangible advantages of embracing automation in the confectionery industry.

Conclusion: Embracing the Future of Confectionery Production

In conclusion, automation presents a wealth of opportunities for confectionery companies to enhance their production processes. By improving efficiency, consistency, and safety, while also reducing costs and adapting to market changes, automation is a key ingredient in the recipe for success in the confectionery industry. As technology continues to advance, the potential for automation to innovate and transform the sector is boundless.

ETprotein: Enhancing Confectionery with High-Quality Protein Products

While automation optimizes production, the quality of ingredients remains crucial for confectionery companies. ETprotein offers a range of high-quality protein products that can enrich confections, catering to the growing demand for protein-enriched snacks and treats. Their organic, non-GMO, allergen-free proteins, including rice, pea, and various seed proteins, provide a neutral taste that seamlessly integrates into confectionery recipes. Additionally, ETprotein’s L-(+)-Ergothioneine (EGT) products offer antioxidant properties that can benefit health-conscious consumers.

For confectionery companies looking to innovate their product lines with nutritious ingredients, ETprotein’s offerings are an excellent choice. Their commitment to quality and customer service makes them a valuable partner in the confectionery industry.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.