How Can Bakers Achieve Process Efficiency?

-

Table of Contents

- Maximizing Bakery Process Efficiency: Strategies for Success

- Understanding the Importance of Process Efficiency in Baking

- Strategies for Enhancing Bakery Process Efficiency

- Invest in Quality Equipment and Technology

- Optimize Workflow and Layout

- Implement Standard Operating Procedures (SOPs)

- Focus on Preventive Maintenance

- Train and Empower Your Staff

- Monitor and Analyze Performance

- Reduce Waste and Improve Sustainability

- Case Studies and Statistics

- Conclusion: Key Takeaways for Bakers

- Enhance Your Baking with ETprotein’s High-Quality Protein Products

Maximizing Bakery Process Efficiency: Strategies for Success

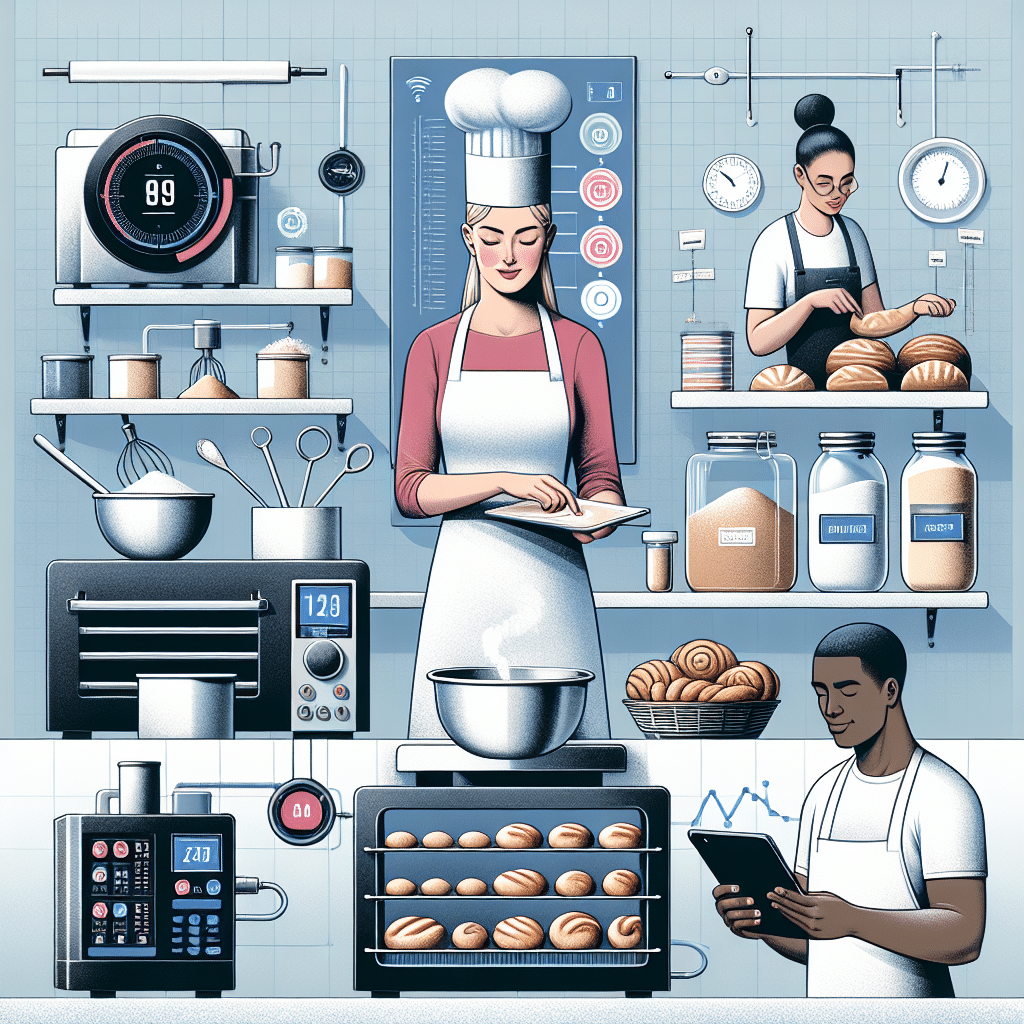

In the competitive world of baking, efficiency is key. Whether you’re running a small patisserie or a large-scale commercial bakery, streamlining your processes can lead to increased productivity, reduced costs, and higher profits. Achieving process efficiency in baking requires a combination of smart planning, the right equipment, and continuous improvement. In this article, we’ll explore actionable strategies that bakers can implement to optimize their operations.

Understanding the Importance of Process Efficiency in Baking

Process efficiency in the baking industry is not just about speed; it’s about making the best use of resources, minimizing waste, and ensuring consistent product quality. Efficient processes can help bakers meet customer demands, adhere to food safety standards, and stay ahead of the competition. With the global bakery products market expected to reach USD 591.34 billion by 2028, according to a report by Grand View Research, the pressure to operate efficiently has never been greater.

Strategies for Enhancing Bakery Process Efficiency

Invest in Quality Equipment and Technology

One of the most effective ways to improve efficiency is to invest in high-quality baking equipment and technology. Automation can significantly reduce manual labor and increase consistency. For instance, automated mixers can ensure precise ingredient measurements, while conveyor systems can streamline the movement of products through different stages of production.

Optimize Workflow and Layout

The layout of your bakery can have a profound impact on efficiency. An optimized workflow minimizes unnecessary movement and allows for a smooth transition between tasks. Consider the placement of equipment, storage areas, and workstations to create a logical flow that reduces bottlenecks and improves productivity.

Implement Standard Operating Procedures (SOPs)

Clear and consistent SOPs ensure that all staff members are aware of the most efficient ways to perform their tasks. This not only improves efficiency but also maintains product quality and safety. Regularly review and update your SOPs to reflect any changes in processes or equipment.

Focus on Preventive Maintenance

Regular maintenance of baking equipment can prevent unexpected breakdowns that disrupt production. Implement a preventive maintenance schedule to keep machines in optimal condition and reduce the likelihood of costly repairs and downtime.

Train and Empower Your Staff

Well-trained employees are essential for efficient operations. Invest in ongoing training programs to ensure that your staff is proficient with the latest equipment and techniques. Encourage a culture of continuous improvement by involving employees in process optimization discussions.

Monitor and Analyze Performance

Tracking key performance indicators (KPIs) such as production times, ingredient usage, and product waste can help identify areas for improvement. Use this data to make informed decisions about process changes and investments.

Reduce Waste and Improve Sustainability

Efficiency also means minimizing waste. Implement practices such as proper ingredient storage, inventory management, and recycling to reduce waste and improve sustainability. This not only benefits the environment but can also lead to cost savings.

Case Studies and Statistics

Real-world examples demonstrate the impact of efficiency improvements in the baking industry. For instance, a study by the American Society of Baking showed that bakeries that automated their packaging lines saw a 50% reduction in labor costs. Another report by PMMI Business Intelligence found that the implementation of robotics and automation in food packaging operations can increase production speed by up to 30%.

Conclusion: Key Takeaways for Bakers

To achieve process efficiency, bakers should focus on investing in technology, optimizing workflows, implementing SOPs, maintaining equipment, training staff, monitoring performance, and reducing waste. By adopting these strategies, bakeries can improve their bottom line and remain competitive in a rapidly evolving industry.

Enhance Your Baking with ETprotein’s High-Quality Protein Products

Efficiency in baking isn’t just about processes; it’s also about using the best ingredients. ETprotein offers a range of high-quality protein products that can enhance your baked goods. Their organic and non-GMO proteins, such as rice, pea, and pumpkin seed proteins, provide excellent nutritional profiles and functional benefits for a variety of bakery applications. Consider incorporating ETprotein’s products into your recipes for an added health appeal and quality assurance.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.