How Do You Make Hydrolyzed Protein?

-

Table of Contents

- Hydrolyzed Protein Production: A Comprehensive Guide

- Understanding Hydrolyzed Protein

- The Hydrolysis Process

- Selection of Protein Source

- Preparation of Protein Solution

- Hydrolysis

- Neutralization and Purification

- Drying

- Testing and Quality Control

- Applications of Hydrolyzed Protein

- Benefits of Hydrolyzed Protein

- Conclusion: Key Takeaways in Hydrolyzed Protein Production

- Discover ETprotein’s Premium Hydrolyzed Proteins

Hydrolyzed Protein Production: A Comprehensive Guide

Proteins are essential macromolecules that play a critical role in virtually all biological processes. In the food and supplement industry, proteins are not only valued for their nutritional benefits but also for their functional properties. Hydrolyzed proteins, in particular, have gained popularity due to their enhanced digestibility and reduced allergenic potential. This article delves into the process of making hydrolyzed protein, exploring the methods, applications, and benefits of this versatile product.

Understanding Hydrolyzed Protein

Before we explore the production process, it’s important to understand what hydrolyzed protein is. Hydrolysis is a chemical process that breaks down protein molecules into smaller peptides or free amino acids by the addition of water. This process mimics our natural digestive actions but occurs outside the body, typically using enzymes or acids. The resulting hydrolyzed protein is easier for the body to absorb and less likely to cause allergic reactions.

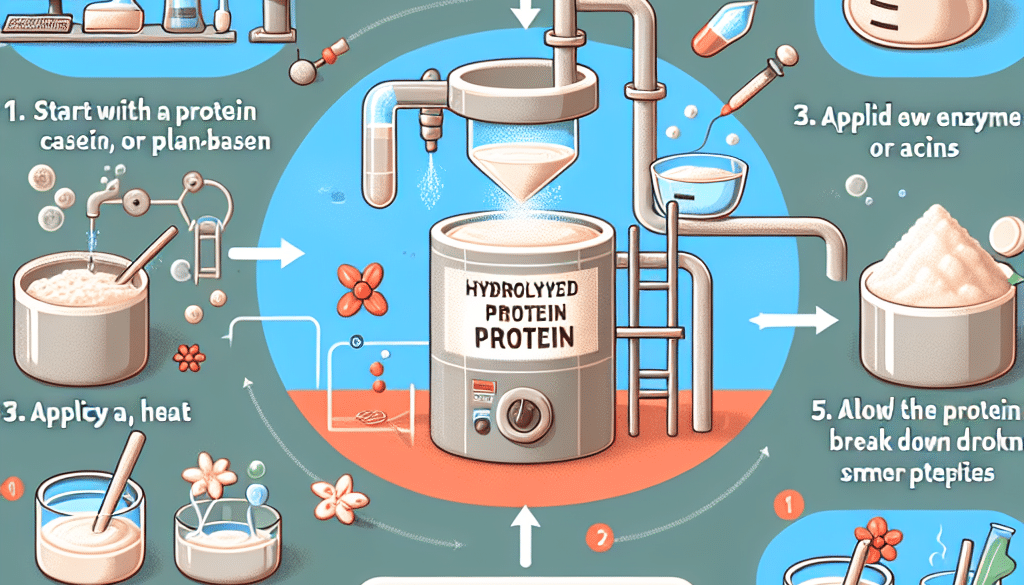

The Hydrolysis Process

The production of hydrolyzed protein involves several key steps, each critical to achieving the desired product quality and functionality.

Selection of Protein Source

The first step in making hydrolyzed protein is selecting an appropriate protein source. Common sources include:

- Whey protein

- Casein

- Soy protein

- Collagen

- Rice protein

- Pea protein

Each source offers different properties and may be chosen based on the intended application of the hydrolyzed protein.

Preparation of Protein Solution

The selected protein is then prepared into a solution, which typically involves dissolving the protein in water. The concentration of the protein solution can vary depending on the desired degree of hydrolysis and the end-use of the product.

Hydrolysis

Hydrolysis can be achieved through two main methods:

- Enzymatic Hydrolysis: Specific enzymes are added to the protein solution to cleave peptide bonds. The type of enzyme used depends on the protein source and the desired peptide length. Enzymatic hydrolysis allows for more control over the process and typically results in a product with a less bitter taste.

- Acid or Alkaline Hydrolysis: This method uses strong acids or bases to break down the protein. While it is a more aggressive approach and can lead to a bitter-tasting product, it is sometimes preferred for its simplicity and cost-effectiveness.

The hydrolysis reaction is carefully monitored and controlled to achieve the desired degree of hydrolysis, which affects the taste, solubility, and functional properties of the final product.

Neutralization and Purification

After hydrolysis, the solution is neutralized if acids or bases were used. The hydrolyzed protein is then purified to remove any unwanted substances, such as residual enzymes, acids, or salts. This step is crucial for ensuring the safety and quality of the final product.

Drying

The purified hydrolyzed protein solution is then dried to remove moisture. Spray drying is a common method used, as it quickly dries the protein while preserving its nutritional and functional properties.

Testing and Quality Control

Finally, the hydrolyzed protein undergoes rigorous testing to ensure it meets quality standards. Parameters such as protein content, degree of hydrolysis, microbial content, and taste are evaluated.

Applications of Hydrolyzed Protein

Hydrolyzed proteins are used in a variety of products due to their enhanced solubility, digestibility, and reduced allergenicity. Some common applications include:

- Infant formula

- Sports nutrition supplements

- Weight management products

- Medical nutrition

- Food and beverage fortification

Benefits of Hydrolyzed Protein

Hydrolyzed proteins offer several advantages over their non-hydrolyzed counterparts:

- Improved digestibility and faster absorption

- Reduced potential for allergic reactions

- Enhanced solubility and stability in various pH conditions

- Functional properties such as foaming, emulsification, and gelation

Conclusion: Key Takeaways in Hydrolyzed Protein Production

In summary, the production of hydrolyzed protein is a sophisticated process that transforms proteins into more digestible and functional ingredients. The careful selection of protein sources, precise control of the hydrolysis process, and stringent quality control are essential to producing high-quality hydrolyzed proteins. These proteins are invaluable in various industries, offering nutritional and functional benefits that cater to the needs of diverse consumer groups.

Discover ETprotein’s Premium Hydrolyzed Proteins

If you’re in search of top-quality hydrolyzed proteins, ETprotein offers an extensive range of products that meet the highest industry standards. Their offerings include organic rice protein, pea protein, and various seed proteins, all characterized by their neutral taste, non-GMO, and allergen-free attributes. With purity levels exceeding 98%, ETprotein’s hydrolyzed proteins are ideal for nutraceutical, pharmaceutical, and food and beverage applications.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.