How Does the Bread-Making Process Work?

-

Table of Contents

- Bread-Making Process: A Comprehensive Guide to Crafting the Perfect Loaf

- Understanding the Basics of Bread-Making

- The Key Ingredients and Their Roles

- The Bread-Making Process Step by Step

- Mixing the Ingredients

- Kneading the Dough

- First Fermentation (Bulk Fermentation)

- Punching Down and Shaping

- Second Fermentation (Proofing)

- Baking

- Cooling

- Scientific Insights into Bread-Making

- Conclusion: The Art and Science of Bread-Making

- Enhance Your Bread with ETprotein’s High-Quality Protein Products

Bread-Making Process: A Comprehensive Guide to Crafting the Perfect Loaf

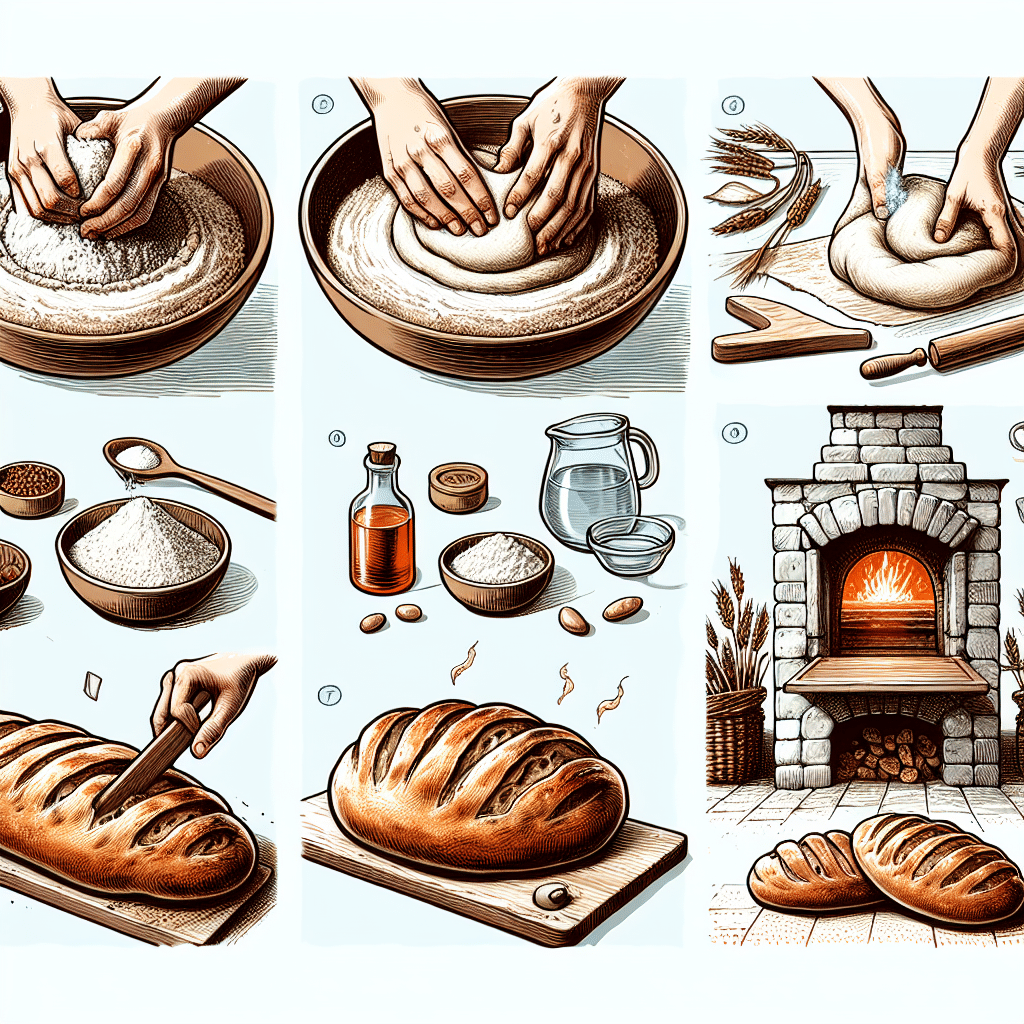

The art of bread-making is as old as civilization itself, with its roots tracing back to ancient times. Today, it remains a fundamental part of our diet and culture. The process of making bread may seem simple—mixing flour, water, yeast, and salt—but the chemistry and techniques involved are quite complex. In this article, we will delve into the bread-making process, exploring each step in detail and providing valuable insights into the science behind creating the perfect loaf.

Understanding the Basics of Bread-Making

Bread-making is a process that transforms basic ingredients into a fluffy, aromatic product through a series of steps including mixing, fermenting, shaping, proofing, and baking. Each stage is crucial and contributes to the final texture, flavor, and appearance of the bread.

The Key Ingredients and Their Roles

- Flour: The foundation of bread, providing structure through gluten formation.

- Water: Hydrates the flour, activates yeast, and helps gluten development.

- Yeast: A living organism that ferments sugars, producing carbon dioxide and alcohol, which cause the dough to rise.

- Salt: Strengthens gluten structure and enhances flavor.

The Bread-Making Process Step by Step

Mixing the Ingredients

The first step in bread-making is combining the ingredients. The goal during mixing is to evenly distribute the yeast and to hydrate the flour. This can be done by hand or with a mixer. The duration of mixing affects gluten development, which is essential for the bread’s texture.

Kneading the Dough

Kneading is the process of working the dough to develop gluten, which gives bread its elasticity and chewiness. This can be done by hand or with a dough hook on a mixer. The dough is kneaded until it becomes smooth and passes the “windowpane test,” indicating that the gluten is well-developed.

First Fermentation (Bulk Fermentation)

After kneading, the dough is left to ferment. During this stage, yeast consumes sugars in the flour, producing carbon dioxide and alcohol. This causes the dough to rise and develop flavor. The duration of this step can vary, but it typically lasts 1-2 hours at room temperature.

Punching Down and Shaping

Once the dough has doubled in size, it is “punched down” to release excess gas. The dough is then shaped into loaves or other forms. Proper shaping is important for even baking and final appearance.

Second Fermentation (Proofing)

The shaped dough undergoes a second rise, or proofing, which allows for further flavor development and volume increase. This step is shorter than the bulk fermentation and is often done in a warm, humid environment to encourage yeast activity.

Baking

Baking transforms the risen dough into bread. The high heat causes the dough to expand rapidly in a process known as “oven spring.” The crust forms and browns due to the Maillard reaction and caramelization of sugars. Baking times and temperatures vary depending on the type of bread.

Cooling

After baking, bread must be cooled on a wire rack to prevent it from becoming soggy. Cooling allows the structure to set and flavors to mature.

Scientific Insights into Bread-Making

The science behind bread-making is fascinating. Gluten development, yeast fermentation, and starch gelatinization are all critical chemical reactions that occur during the process. For instance, optimal fermentation temperature for yeast is between 75°F and 78°F (24°C to 26°C), and the ideal protein content in flour for bread-making is around 12% to 14%.

Conclusion: The Art and Science of Bread-Making

Bread-making is both an art and a science. It requires precision, patience, and a deep understanding of the ingredients and processes involved. By following the steps outlined above and respecting the chemistry of bread-making, bakers can consistently produce delicious and high-quality loaves.

Enhance Your Bread with ETprotein’s High-Quality Protein Products

For those looking to enrich their bread with additional nutritional benefits, ETprotein offers a range of high-quality protein products. Incorporating organic rice protein or pea protein into your bread recipe can boost its protein content, making it a more satisfying and healthful option. ETprotein’s products are non-GMO, allergen-free, and come with a neutral taste, ensuring that your bread retains its delicious flavor while being nutritionally enhanced.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.