How Is Hydrolyzed Pea Protein Made?

-

Table of Contents

- Hydrolyzed Pea Protein: Production Process and Benefits

- Understanding Hydrolyzed Pea Protein

- The Production Process of Hydrolyzed Pea Protein

- Step 1: Sourcing and Cleaning the Peas

- Step 2: Pea Protein Isolation

- Step 3: Protein Hydrolyzation

- Step 4: Purification and Drying

- Step 5: Quality Control and Packaging

- Benefits of Hydrolyzed Pea Protein

- Applications in Various Industries

- Conclusion

- Discover ETprotein’s Premium Protein Products

Hydrolyzed Pea Protein: Production Process and Benefits

As the demand for plant-based proteins continues to rise, hydrolyzed pea protein has emerged as a popular alternative to animal-derived proteins. This sustainable and allergen-friendly protein source is gaining traction among health-conscious consumers and those with dietary restrictions. In this article, we will delve into the production process of hydrolyzed pea protein, its benefits, and its applications in various industries.

Understanding Hydrolyzed Pea Protein

Hydrolyzed pea protein is derived from yellow peas, known scientifically as Pisum sativum. It is a high-quality protein that contains all nine essential amino acids, making it a complete protein source. The hydrolyzation process breaks down the protein into smaller peptides, which can enhance digestibility and absorption.

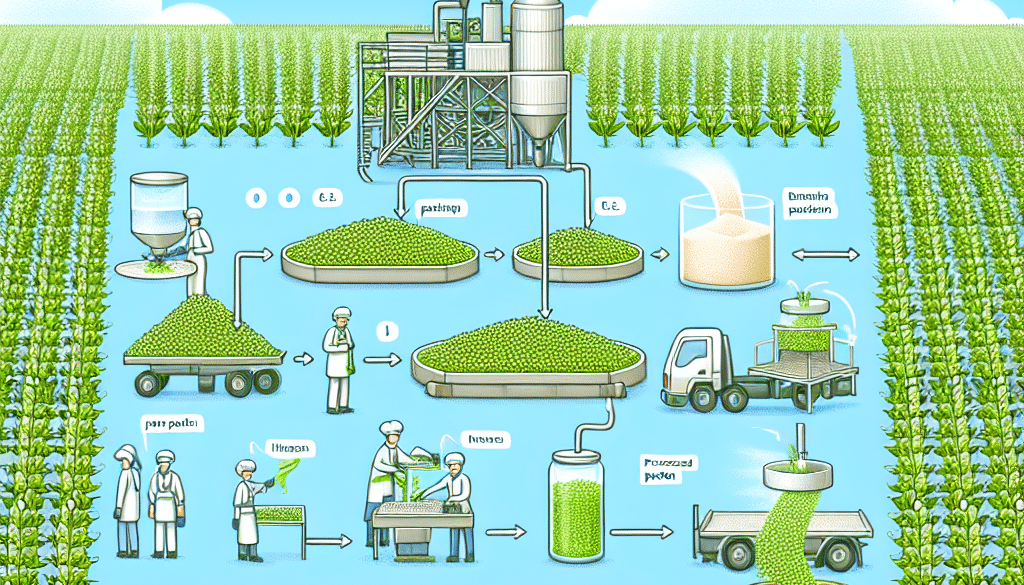

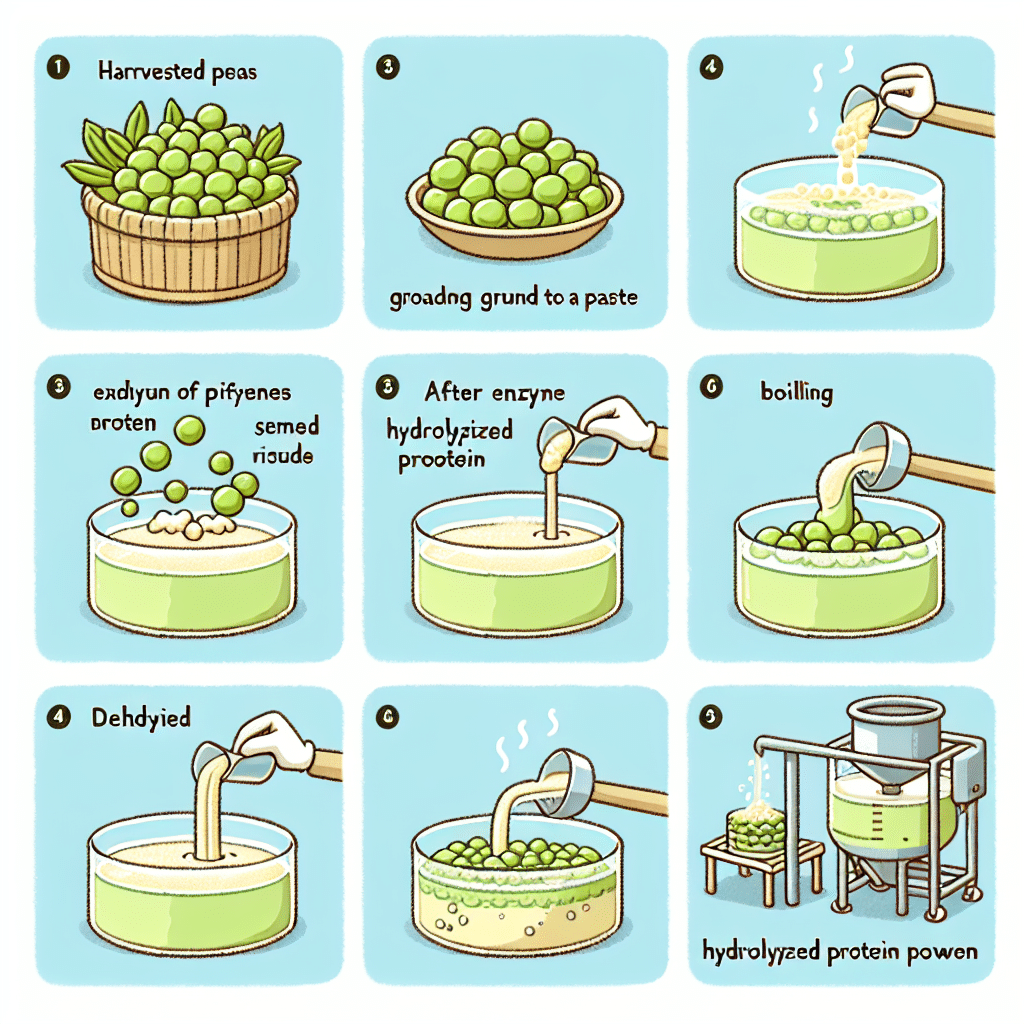

The Production Process of Hydrolyzed Pea Protein

The manufacturing of hydrolyzed pea protein involves several steps, each crucial to ensuring the final product’s quality and purity.

Step 1: Sourcing and Cleaning the Peas

The process begins with sourcing high-quality yellow peas. Once harvested, the peas undergo thorough cleaning to remove impurities and foreign materials.

Step 2: Pea Protein Isolation

The cleaned peas are then ground into flour and mixed with water to create a slurry. The slurry is processed to separate the protein from the fiber and starch. This is typically done using a combination of centrifugation and filtration techniques.

Step 3: Protein Hydrolyzation

The isolated pea protein is then hydrolyzed. This involves treating the protein with enzymes that break down the protein chains into smaller peptides. The degree of hydrolyzation can be controlled to achieve the desired molecular weight and functional properties.

Step 4: Purification and Drying

After hydrolyzation, the protein solution is purified to remove any remaining impurities. It is then dried using spray drying or freeze-drying methods to produce a fine, powdered hydrolyzed pea protein.

Step 5: Quality Control and Packaging

The final product undergoes rigorous quality control testing to ensure it meets industry standards. Once approved, the hydrolyzed pea protein is packaged for distribution.

Benefits of Hydrolyzed Pea Protein

Hydrolyzed pea protein offers several advantages over other protein sources:

- Hypoallergenic: It is a safe option for individuals with common food allergies, such as those to dairy or soy.

- High Digestibility: The hydrolyzation process enhances the digestibility of the protein, making it easier for the body to absorb and utilize.

- Complete Amino Acid Profile: It contains all nine essential amino acids required for human health.

- Sustainability: Pea protein production has a lower environmental footprint compared to animal-based proteins.

- Versatility: Hydrolyzed pea protein can be used in a wide range of products, from nutritional supplements to plant-based meats.

Applications in Various Industries

Hydrolyzed pea protein has found applications in numerous industries due to its functional properties:

- Food and Beverage: It is used in products like protein bars, shakes, and plant-based dairy alternatives.

- Sports Nutrition: Athletes and fitness enthusiasts utilize hydrolyzed pea protein for muscle recovery and growth.

- Weight Management: Its high protein content can promote satiety and aid in weight loss efforts.

- Health and Wellness: It is incorporated into dietary supplements for those seeking to increase their protein intake.

Conclusion

Hydrolyzed pea protein is a versatile and sustainable protein source that caters to a growing market of health-conscious consumers. Its production process, from sourcing to hydrolyzation, ensures a high-quality product that is digestible, allergen-free, and nutritionally complete. As the plant-based protein trend continues to flourish, hydrolyzed pea protein is poised to play a significant role in the future of food and nutrition.

Discover ETprotein’s Premium Protein Products

If you’re interested in incorporating high-quality hydrolyzed pea protein into your diet or products, ETprotein offers an exceptional range of protein solutions. Their hydrolyzed pea protein is characterized by its neutral taste, non-GMO status, and allergen-free attributes, making it an excellent choice for various applications.

ETprotein’s commitment to quality and customer satisfaction extends to their entire product line, which includes organic rice protein, clear rice protein, and other plant-based proteins, as well as L-(+)-Ergothioneine in various grades. Catering to industries such as nutraceuticals, pharmaceuticals, cosmeceuticals, and food and beverage, ETprotein is a trusted supplier for businesses around the world.

To learn more about ETprotein’s offerings or to request a sample, contact their team at sales(at)ETprotein.com today.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.