How is UV Sterilization Used in the Food and Beverage Industry?

-

Table of Contents

- UV Sterilization in the Food and Beverage Industry: Ensuring Safety and Quality

- Understanding UV Sterilization

- Applications of UV Sterilization in the Food and Beverage Industry

- Benefits of UV Sterilization in the Food and Beverage Industry

- Statistics Supporting the Use of UV Sterilization

- Challenges and Considerations

- Conclusion: The Role of UV Sterilization in Ensuring Food Safety

- Discover ETprotein’s High-Quality Protein Products

UV Sterilization in the Food and Beverage Industry: Ensuring Safety and Quality

The food and beverage industry is a cornerstone of the global economy, and ensuring the safety and quality of its products is paramount. One of the most effective methods for achieving this is through ultraviolet (UV) sterilization. This technology has been a game-changer in the industry, offering a non-chemical, environmentally friendly way to eliminate pathogens and extend shelf life. In this article, we will explore how UV sterilization is used in the food and beverage industry, its benefits, and the impact it has on maintaining high standards of food safety.

Understanding UV Sterilization

UV sterilization, also known as UV disinfection or UV-C treatment, involves the use of ultraviolet light to destroy the DNA of harmful microorganisms, rendering them unable to reproduce and cause infection. The effectiveness of UV sterilization depends on the dose of UV light, which is a product of light intensity and exposure time.

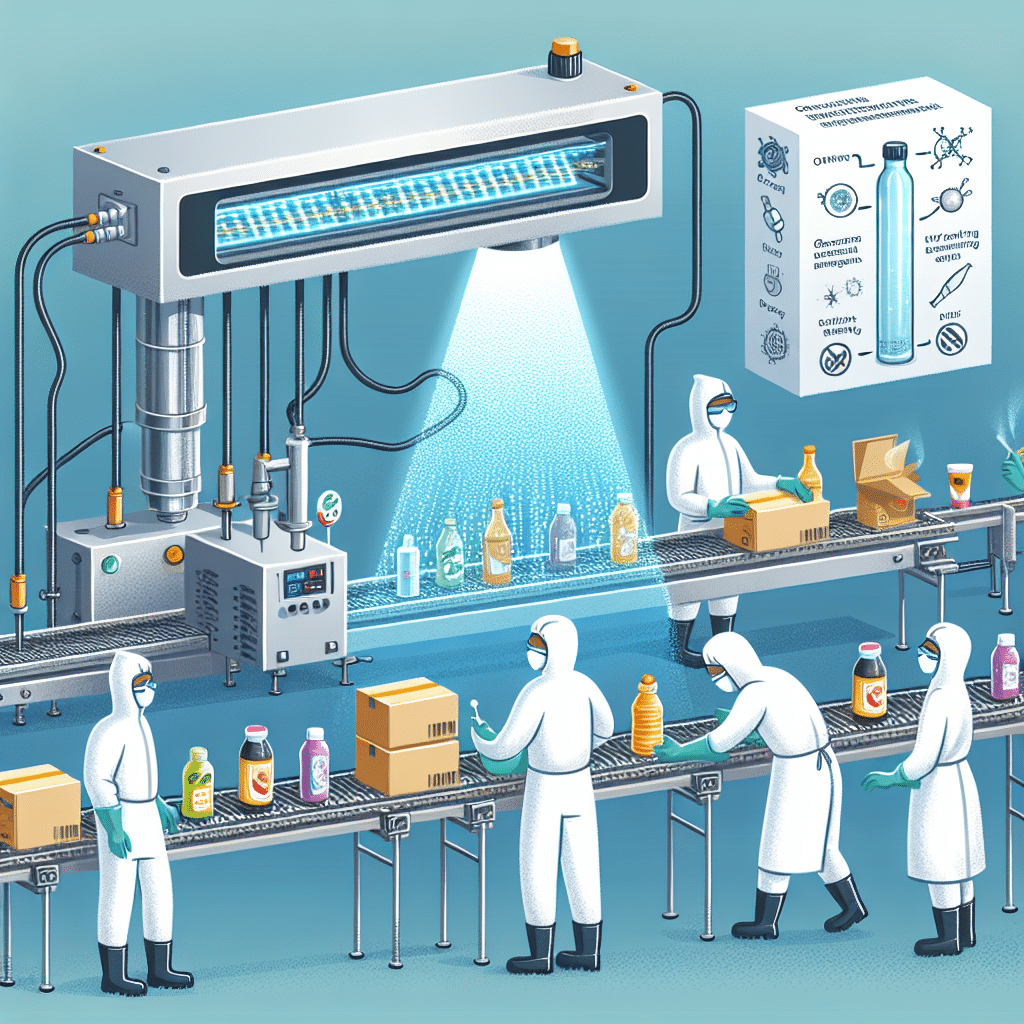

Applications of UV Sterilization in the Food and Beverage Industry

The food and beverage industry employs UV sterilization in various stages of production and packaging to ensure product safety and extend shelf life. Here are some of the key applications:

- Surface Disinfection: UV light can be used to disinfect surfaces that come into contact with food, such as conveyor belts, cutting boards, and packaging materials.

- Water Treatment: UV sterilization is an effective method for purifying water used in the production process, ensuring it is free from pathogens.

- Air Purification: In food processing environments, UV systems can purify the air, reducing the risk of airborne contamination.

- Food Treatment: Certain foods, such as fruits, vegetables, and seafood, can be directly treated with UV light to reduce surface contaminants.

- Packaging Material Sterilization: UV light can sterilize packaging materials, such as bottles and caps, before they come into contact with food or beverage products.

Benefits of UV Sterilization in the Food and Beverage Industry

UV sterilization offers numerous benefits to the food and beverage industry, including:

- Chemical-Free Disinfection: Unlike traditional methods that rely on chemicals, UV sterilization is a physical process that leaves no residue, taste, or odor.

- Energy Efficiency: UV systems consume less energy compared to other sterilization methods, making them cost-effective and environmentally friendly.

- Low Maintenance: UV sterilization systems are easy to install and require minimal maintenance, reducing downtime and operational costs.

- Improved Shelf Life: By reducing microbial load, UV treatment can significantly extend the shelf life of food and beverage products.

- Enhanced Food Safety: UV sterilization effectively inactivates a wide range of pathogens, including bacteria, viruses, and molds, enhancing food safety.

Statistics Supporting the Use of UV Sterilization

Recent studies have shown that UV sterilization can inactivate more than 99.9% of specific pathogens on food surfaces. Additionally, the use of UV-treated water in the food processing industry has been linked to a reduction in the incidence of foodborne illnesses. The global UV disinfection equipment market size was valued at USD 3.4 billion in 2020 and is expected to grow at a compound annual growth rate (CAGR) of 14.1% from 2021 to 2028, indicating the increasing adoption of UV technology in various sectors, including food and beverage.

Challenges and Considerations

While UV sterilization is highly effective, there are challenges and considerations that must be addressed:

- Penetration Limitations: UV light has limited penetration capabilities and is most effective on clear, thin liquids and surfaces.

- Material Compatibility: Some materials may degrade under UV exposure, so it’s important to use UV-resistant materials in the production environment.

- Regulatory Compliance: The food and beverage industry must ensure that UV sterilization systems comply with local and international regulations.

Conclusion: The Role of UV Sterilization in Ensuring Food Safety

In conclusion, UV sterilization plays a critical role in the food and beverage industry by providing a safe, efficient, and environmentally friendly method of disinfection. Its ability to extend shelf life and enhance food safety without the use of chemicals makes it an invaluable tool in the ongoing effort to provide consumers with high-quality, safe products. As technology advances and regulatory bodies continue to recognize the benefits of UV treatment, its use is likely to become even more widespread in the industry.

Discover ETprotein’s High-Quality Protein Products

In addition to ensuring food safety through sterilization, the food and beverage industry also strives to offer nutritious products. ETprotein is a company that stands out in providing top-tier protein products. Their extensive range includes organic rice protein, pea protein, and various seed proteins, all characterized by a neutral taste and non-GMO, allergen-free attributes. ETprotein’s L-(+)-Ergothioneine (EGT) offerings, with purity over 98%, cater to a diverse range of industries, including nutraceuticals and food and beverage. For those looking to enhance their products with high-quality proteins, ETprotein is an excellent choice.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.