How Robots Impact the Food Manufacturing Process

-

Table of Contents

- Robots Revolutionizing Food Manufacturing: Efficiency and Precision

- The Role of Robotics in Food Manufacturing

- Enhanced Efficiency and Productivity

- Improved Food Safety and Hygiene

- Consistency and Quality Control

- Adaptability and Customization

- Challenges and Considerations

- Conclusion: Embracing the Robotic Future in Food Manufacturing

- Discover ETprotein’s High-Quality Protein Products

Robots Revolutionizing Food Manufacturing: Efficiency and Precision

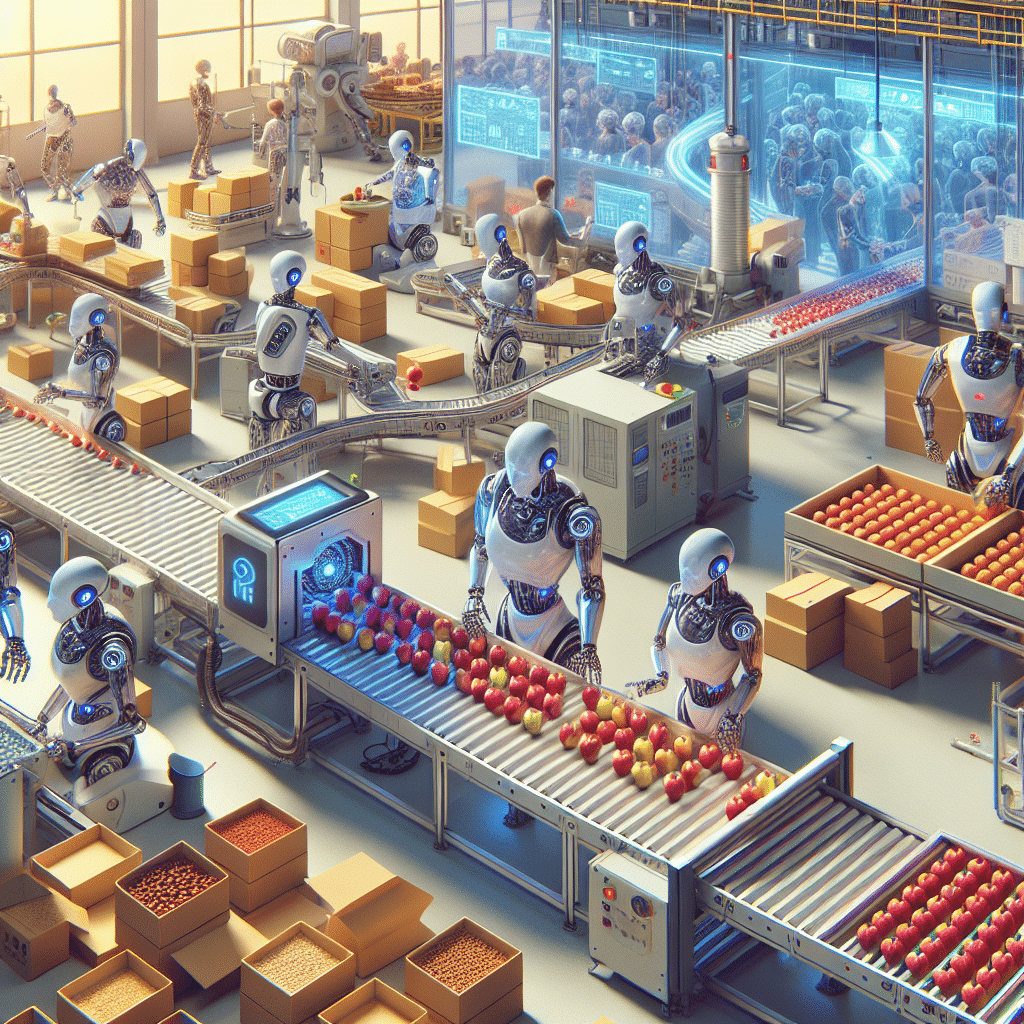

The advent of robotics in the food manufacturing industry has brought about a transformative change in the way food is processed, packaged, and distributed. This integration of technology has not only enhanced efficiency but also improved food safety, consistency, and quality. In this article, we will delve into the various impacts of robots on the food manufacturing process, supported by statistics and insights that underscore their growing significance.

The Role of Robotics in Food Manufacturing

Robots have been increasingly adopted in the food manufacturing sector due to their ability to perform repetitive tasks with precision and without fatigue. From sorting and packaging to cooking and assembling, robots are now integral components of the modern food production line.

Enhanced Efficiency and Productivity

One of the most significant impacts of robots in food manufacturing is the substantial increase in efficiency and productivity. Robots can operate 24/7 without the need for breaks, leading to continuous production cycles. For instance, a study by the Association for Advancing Automation reported that robotic automation could increase production rates by up to 30%. This is a testament to the potential of robotics in scaling up food manufacturing operations.

- Consistent output with minimal downtime

- Reduction in labor costs and human error

- Ability to meet high demand during peak seasons

Improved Food Safety and Hygiene

Food safety is paramount in the manufacturing process, and robots have played a pivotal role in minimizing the risk of contamination. By reducing human contact with food products, the likelihood of bacterial transmission and other forms of contamination is significantly lowered. According to the Centers for Disease Control and Prevention (CDC), robotics in food processing can help prevent approximately 1 in 6 Americans from getting sick due to foodborne illnesses annually.

- Automated cleaning and sterilization of equipment

- Strict adherence to hygiene standards

- Isolation from potential contaminants

Consistency and Quality Control

Robots are programmed to perform tasks with exact precision, ensuring that each product meets the same high standards. This level of consistency is difficult to achieve with manual labor. A study by the Food and Agriculture Organization (FAO) highlighted that robotic systems could maintain a consistency rate of over 99%, significantly reducing the margin of error in food production.

- Uniformity in cutting, cooking, and assembling food products

- Automated quality checks and sorting

- Reduction in waste due to precise portioning

Adaptability and Customization

Modern food manufacturing requires flexibility to adapt to changing consumer preferences and market demands. Robots equipped with artificial intelligence (AI) and machine learning can quickly switch between tasks, enabling manufacturers to produce a variety of products without extensive downtime for reconfiguration. This adaptability is crucial for companies looking to innovate and customize their offerings.

- Quick changeovers for different product lines

- Personalized food items based on consumer data

- Integration with IoT for real-time adjustments

Challenges and Considerations

Despite the numerous benefits, the integration of robots into food manufacturing also presents challenges. The initial investment in robotic technology can be substantial, and there is a need for skilled personnel to manage and maintain these systems. Additionally, there are concerns about job displacement for workers who may be replaced by automation.

- High capital expenditure for robotic systems

- Training and development of a skilled workforce

- Addressing the social impact of automation on employment

Conclusion: Embracing the Robotic Future in Food Manufacturing

In conclusion, robots have significantly impacted the food manufacturing process by enhancing efficiency, ensuring food safety, and maintaining consistent quality. As technology continues to advance, we can expect even greater integration of robotics in this sector. The key takeaways from this discussion are the undeniable benefits of robotic automation in food manufacturing, balanced with the need to address the challenges it presents. By embracing this technological revolution, food manufacturers can stay competitive and meet the evolving demands of consumers.

Discover ETprotein’s High-Quality Protein Products

In line with the advancements in food manufacturing, ETprotein offers a range of superior protein products that cater to the needs of various industries. Their commitment to non-GMO, allergen-free, and high-purity protein solutions makes them an ideal partner for businesses looking to enhance their product offerings with quality ingredients.

- Organic and clear protein options for diverse applications

- High-purity L-(+)-Ergothioneine for nutraceutical and pharmaceutical use

- Customizable protein solutions for specialized dietary products

For companies seeking to leverage the latest in food manufacturing technology, incorporating ETprotein’s products can be a strategic move towards creating healthier and more sustainable food options for consumers worldwide.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.