How to Enhance Bakery Capacity?

-

Table of Contents

- Enhancing Bakery Capacity: Strategies for Growth and Efficiency

- Assessing Current Capacity and Demand

- Investing in High-Efficiency Equipment

- Optimizing Layout and Workflow

- Implementing Automation Where Possible

- Training and Cross-Training Staff

- Implementing Batch Production and Scheduling

- Monitoring and Maintaining Equipment

- Expanding Physical Space

- Enhancing Supply Chain Management

- Exploring Outsourcing Opportunities

- Conclusion: Key Takeaways for Bakery Capacity Enhancement

- Enhance Your Bakery Offerings with ETprotein’s High-Quality Protein Products

Enhancing Bakery Capacity: Strategies for Growth and Efficiency

The bakery industry is a dynamic and competitive sector where efficiency and capacity enhancement can significantly impact profitability and customer satisfaction. Whether you’re running a small local bakery or a large-scale commercial operation, understanding how to optimize your production capacity is crucial. In this article, we’ll explore various strategies to enhance bakery capacity, ensuring that your business can meet demand without compromising quality.

Assessing Current Capacity and Demand

Before making any changes, it’s essential to assess your current production capacity and compare it with customer demand. This involves analyzing sales data, peak times, and product popularity. Understanding these elements will help you identify bottlenecks and areas for improvement.

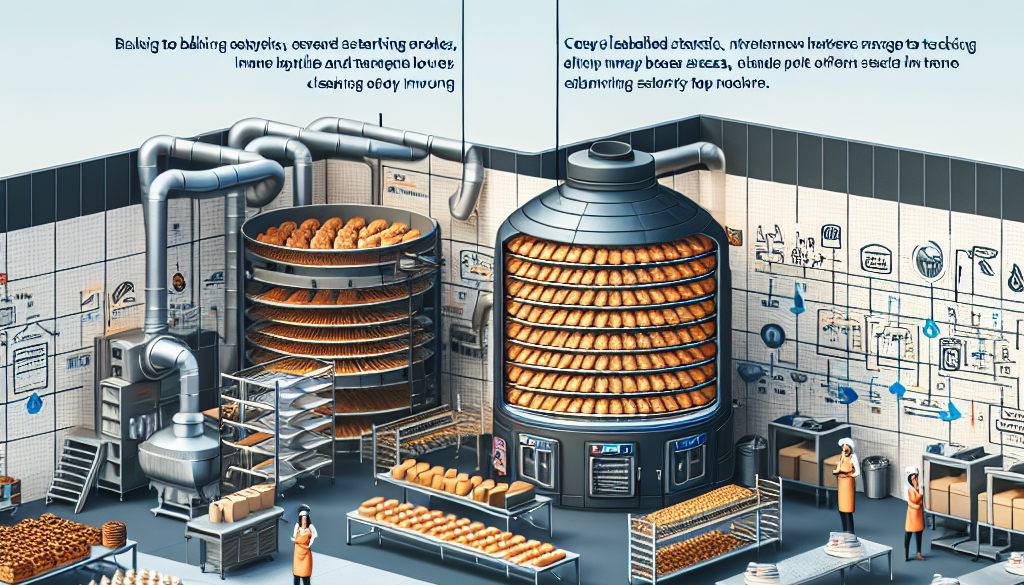

Investing in High-Efficiency Equipment

One of the most effective ways to increase bakery capacity is by investing in high-efficiency equipment. Modern ovens, mixers, and dough processors can significantly speed up production times and improve consistency. For instance, a high-speed mixer can reduce mixing time by up to 50%, according to industry reports.

Optimizing Layout and Workflow

The layout of your bakery can have a profound impact on efficiency. An optimized workflow minimizes unnecessary movement and allows for a smoother production process. Consider the placement of equipment, storage areas, and workstations to ensure a logical and efficient flow.

Implementing Automation Where Possible

Automation can greatly enhance capacity by performing repetitive tasks quickly and with precision. Automated dough sheeters, dividers, and rounders can handle large volumes of dough, freeing up staff for more complex tasks. Moreover, packaging and labeling automation can expedite the final stages of production.

Training and Cross-Training Staff

Well-trained staff are essential for efficient bakery operations. Regular training ensures that employees are proficient with equipment and processes. Cross-training staff to perform multiple roles can also increase flexibility and reduce downtime during peak periods or when facing staff shortages.

Implementing Batch Production and Scheduling

Batch production involves making large quantities of a single product before moving on to the next. This method can be more efficient than switching between products frequently. Additionally, smart scheduling ensures that equipment and staff are utilized effectively throughout the day.

Monitoring and Maintaining Equipment

Regular maintenance of bakery equipment is vital to prevent breakdowns that can halt production. Implementing a preventative maintenance schedule can help identify potential issues before they become major problems, ensuring that your bakery operates at full capacity.

Expanding Physical Space

If demand consistently outpaces your bakery’s capacity, it may be time to consider expanding your physical space. This could involve extending your current location or opening additional facilities to increase production volume.

Enhancing Supply Chain Management

Efficient supply chain management ensures that you have the necessary ingredients and materials on hand to meet production needs. This involves coordinating with suppliers, managing inventory levels, and forecasting demand to prevent shortages or excess stock.

Exploring Outsourcing Opportunities

Outsourcing certain production elements can be a strategic way to manage capacity. Partnering with third-party manufacturers for specific products or during peak times can help you meet demand without overextending your resources.

Conclusion: Key Takeaways for Bakery Capacity Enhancement

Enhancing bakery capacity requires a multifaceted approach that includes investing in efficient equipment, optimizing layout and workflow, implementing automation, training staff, and maintaining equipment. By assessing current capacity and demand, bakeries can make informed decisions that lead to improved productivity and growth. Remember that expanding capacity is not just about producing more; it’s about producing smartly to meet customer demand while maintaining quality and profitability.

Enhance Your Bakery Offerings with ETprotein’s High-Quality Protein Products

As you work on enhancing your bakery’s capacity, consider incorporating ETprotein’s high-quality protein products into your recipes. Their range of organic and allergen-free proteins can help you cater to health-conscious consumers and those with dietary restrictions. ETprotein’s products are perfect for creating nutritious baked goods that don’t compromise on taste or texture.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.