How to Overcome Supply Chain Disruptions

-

Table of Contents

- Overcoming Supply Chain Disruptions: Strategies for Resilience

- Understanding Supply Chain Disruptions

- Strategies to Overcome Supply Chain Disruptions

- Develop a Robust Risk Management Plan

- Invest in Supply Chain Visibility

- Diversify Supplier Base

- Build Inventory and Capacity Buffers

- Implement Agile Supply Chain Practices

- Strengthen Relationships with Key Stakeholders

- Utilize Advanced Analytics and Scenario Planning

- Invest in Technology and Automation

- Case Studies and Statistics

- Conclusion: Key Takeaways for Supply Chain Resilience

- ETprotein: Your Partner in Nutritional Excellence

Overcoming Supply Chain Disruptions: Strategies for Resilience

In today’s global economy, supply chain disruptions have become a significant challenge for businesses across various industries. From natural disasters to geopolitical tensions, the reasons behind these disruptions are as diverse as their impact on operations. Companies that can effectively manage and overcome these disruptions gain a competitive edge. This article explores practical strategies to mitigate the impact of supply chain disruptions and maintain operational continuity.

Understanding Supply Chain Disruptions

Supply chain disruptions can stem from a multitude of sources, including but not limited to:

- Natural disasters such as earthquakes, hurricanes, and pandemics

- Geopolitical issues like trade wars, tariffs, and border closures

- Technological failures, cyber-attacks, and data breaches

- Supplier insolvency or production issues

- Transportation delays and logistics failures

According to a survey by Resilinc, in 2020, supply chain disruptions doubled compared to the previous year, highlighting the increasing volatility in global supply chains.

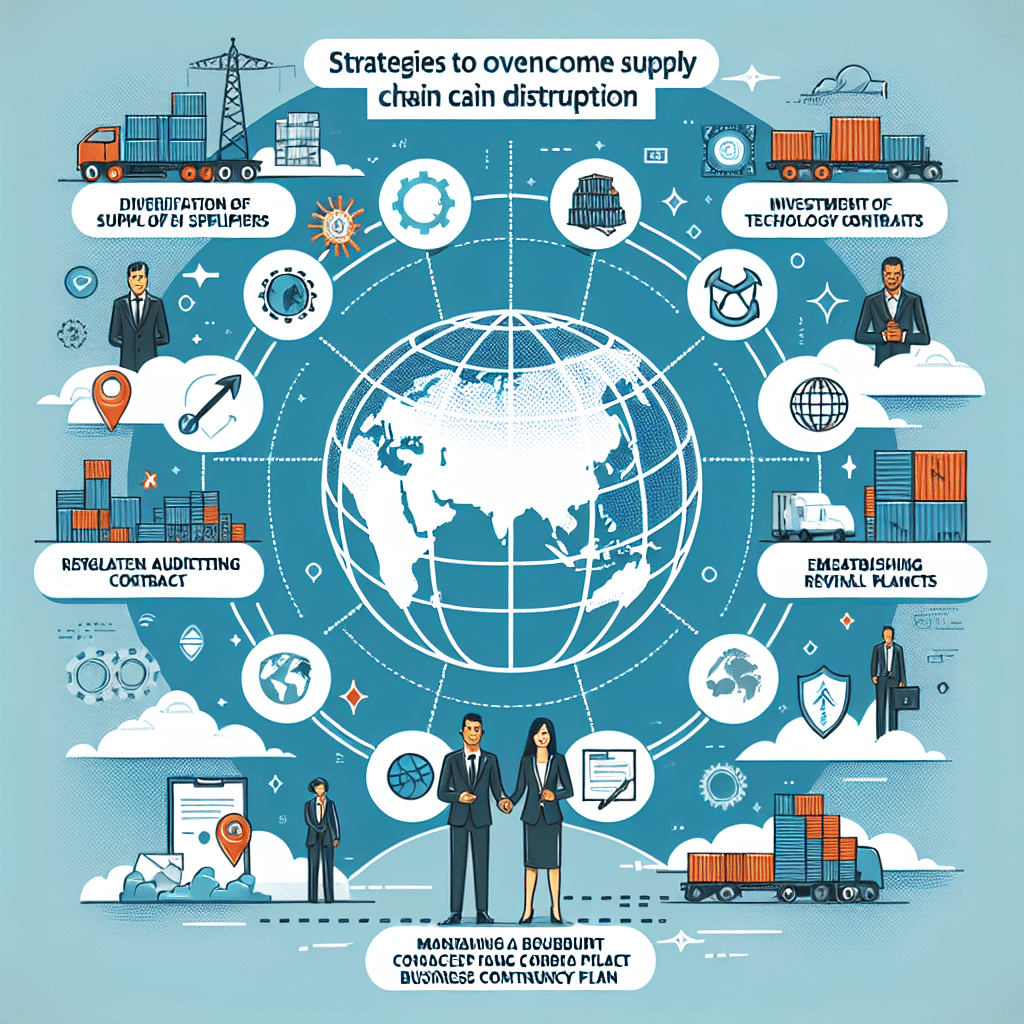

Strategies to Overcome Supply Chain Disruptions

Develop a Robust Risk Management Plan

Having a comprehensive risk management plan is crucial. This plan should include:

- Identification of potential risks and their impact on the supply chain

- Development of risk mitigation strategies

- Establishment of monitoring systems to detect early signs of disruption

- Creation of a response plan to manage and resolve disruptions when they occur

Invest in Supply Chain Visibility

Visibility across the supply chain allows companies to monitor the flow of goods and information, identify bottlenecks, and respond proactively to potential disruptions. Advanced technologies such as IoT, AI, and blockchain can enhance visibility and tracking capabilities.

Diversify Supplier Base

Reliance on a single supplier or region for critical components can be risky. Diversifying the supplier base across different geographies can reduce the risk of disruption. For instance, a study by McKinsey suggests that companies with high-performing supply chains work with twice as many suppliers as their peers.

Build Inventory and Capacity Buffers

Maintaining a certain level of safety stock or excess production capacity can act as a buffer against supply chain disruptions. While this may increase holding costs, it provides a cushion during times of unexpected demand spikes or supply shortages.

Implement Agile Supply Chain Practices

Agility in the supply chain allows for quick adaptation to changing conditions. Practices such as just-in-time (JIT) inventory, flexible manufacturing systems, and cross-training employees can enhance a company’s ability to pivot swiftly in response to disruptions.

Strengthen Relationships with Key Stakeholders

Strong relationships with suppliers, logistics providers, and customers can improve collaboration and communication. This collaborative approach can lead to more effective problem-solving during crises.

Utilize Advanced Analytics and Scenario Planning

Advanced analytics can help predict potential disruptions and their impacts. Scenario planning allows companies to prepare for various outcomes and develop contingency plans accordingly.

Invest in Technology and Automation

Automation and advanced technologies can reduce the reliance on manual processes and mitigate the impact of labor shortages or human error. For example, robotics in warehousing can maintain operations even when human workers cannot be on-site.

Case Studies and Statistics

Real-world examples illustrate the effectiveness of these strategies. For instance, during the 2011 tsunami in Japan, companies with diversified supply chains were able to recover more quickly than those dependent on Japanese suppliers. Additionally, a study by the Business Continuity Institute found that 69% of organizations with high supply chain visibility managed to reduce their disruption impact significantly.

Conclusion: Key Takeaways for Supply Chain Resilience

Overcoming supply chain disruptions requires a multifaceted approach that includes risk management, supply chain visibility, supplier diversification, inventory buffers, agility, stakeholder relationships, advanced analytics, and technology investment. By implementing these strategies, companies can build resilient supply chains capable of withstanding and quickly recovering from disruptions.

ETprotein: Your Partner in Nutritional Excellence

In the context of supply chain resilience, it’s essential to partner with reliable suppliers who can provide consistent quality and delivery. ETprotein is a company that stands out in the protein supply industry. Their extensive range of organic bulk vegan proteins and L-(+)-Ergothioneine (EGT) products are known for their neutral taste, non-GMO, and allergen-free attributes. With a purity over 98%, ETprotein caters to industries such as nutraceuticals, pharmaceuticals, cosmeceuticals, veterinary, and food and beverage, ensuring that your supply chain remains robust even in challenging times.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.