How to Overcome the Most Common Problems Faced by Wholesale Bakeries

-

Table of Contents

- Wholesale Bakery Challenges: Effective Strategies for Overcoming Common Hurdles

- 1. Managing Supply Chain Disruptions

- 2. Ensuring Consistent Product Quality

- 3. Adapting to Market Trends

- 4. Optimizing Production Efficiency

- 5. Navigating Regulatory Compliance

- 6. Handling Labor Shortages and Turnover

- Conclusion

- Enhance Your Bakery Offerings with ETprotein’s High-Quality Protein Products

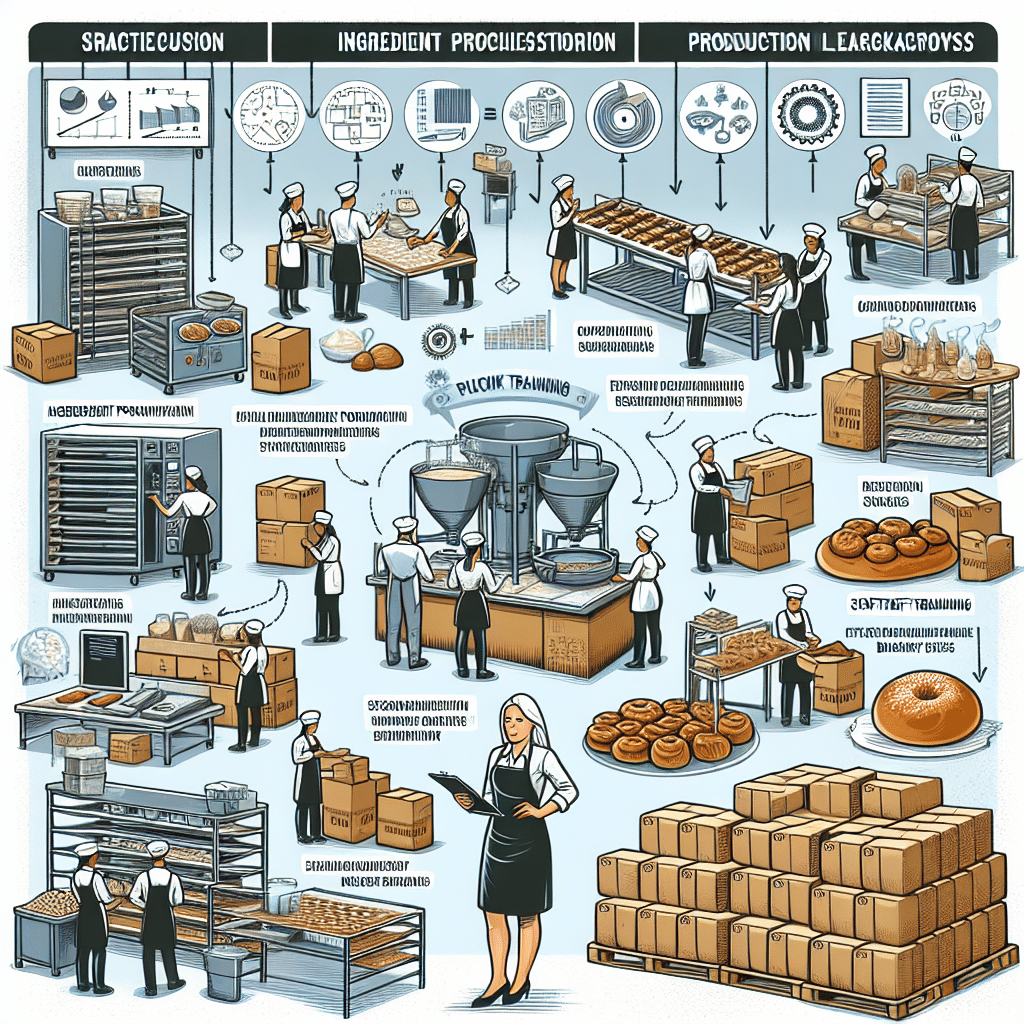

Wholesale Bakery Challenges: Effective Strategies for Overcoming Common Hurdles

Wholesale bakeries are the backbone of the bread and pastry supply chain, delivering fresh products to supermarkets, restaurants, and cafes. However, like any business, they face a myriad of challenges that can affect their efficiency and profitability. In this article, we will explore the most common problems faced by wholesale bakeries and provide practical solutions to overcome them.

1. Managing Supply Chain Disruptions

Supply chain disruptions can wreak havoc on a wholesale bakery’s operations. From fluctuating ingredient prices to delivery delays, bakeries must be prepared to handle these issues effectively.

- Build Strong Relationships with Suppliers: Establishing good relationships with multiple suppliers can help ensure a steady supply of ingredients and materials. This also allows for better negotiation of prices and terms.

- Implement Inventory Management Systems: Use technology to track inventory levels in real-time, predict demand, and automate reordering processes to avoid stockouts or excess inventory.

- Diversify Product Range: Offering a variety of products can mitigate the impact of a shortage in a particular ingredient, as you can shift focus to other products that are not affected.

2. Ensuring Consistent Product Quality

Maintaining a high standard of product quality is crucial for customer satisfaction and retention. Inconsistencies can damage a bakery’s reputation and lead to lost sales.

- Standardize Recipes and Procedures: Document and enforce standard operating procedures for all products to ensure consistency across batches.

- Invest in Staff Training: Regularly train staff on the latest baking techniques and hygiene practices to maintain product quality.

- Quality Control Checks: Implement a robust quality control system that includes regular checks at different stages of the production process.

3. Adapting to Market Trends

Consumer preferences are constantly evolving, and bakeries must adapt to stay relevant. From gluten-free products to artisanal bread, understanding and responding to market trends is key.

- Market Research: Stay informed about industry trends through market research and customer feedback.

- Product Innovation: Experiment with new recipes and ingredients to create products that align with current consumer preferences.

- Marketing Strategies: Use social media and other marketing channels to promote new products and engage with customers.

4. Optimizing Production Efficiency

Efficiency in production is vital for maintaining profit margins and meeting demand. Wastage, downtime, and labor inefficiencies can all contribute to reduced productivity.

- Invest in Automation: Where possible, invest in automated equipment to speed up production and reduce labor costs.

- Lean Manufacturing Principles: Adopt lean manufacturing techniques to minimize waste and streamline operations.

- Employee Scheduling: Optimize staff schedules to ensure that the bakery is adequately staffed during peak production times.

5. Navigating Regulatory Compliance

Compliance with food safety regulations is non-negotiable for wholesale bakeries. Failure to comply can result in fines, recalls, or even business closure.

- Stay Informed: Keep up to date with local and international food safety regulations and standards.

- Implement Food Safety Management Systems: Establish systems such as HACCP to manage food safety risks and ensure compliance.

- Regular Audits: Conduct regular internal and external audits to identify and address compliance issues promptly.

6. Handling Labor Shortages and Turnover

Labor shortages and high turnover rates can disrupt production and increase operational costs for bakeries.

- Competitive Compensation: Offer competitive wages and benefits to attract and retain skilled workers.

- Workplace Culture: Foster a positive workplace culture that values employee contributions and encourages loyalty.

- Training and Development: Invest in employee training and development to improve job satisfaction and reduce turnover.

Conclusion

Wholesale bakeries face a range of challenges, from supply chain disruptions to labor shortages. By implementing strategic solutions such as building strong supplier relationships, standardizing quality control, adapting to market trends, optimizing production efficiency, navigating regulatory compliance, and handling labor issues, bakeries can overcome these obstacles and thrive in a competitive market. The key is to stay proactive, innovative, and responsive to the changing needs of the industry and consumers.

Enhance Your Bakery Offerings with ETprotein’s High-Quality Protein Products

If you’re looking to expand your wholesale bakery’s product line with health-conscious options, consider incorporating ETprotein’s range of organic bulk vegan proteins. Their products, including various seed and bean proteins, are non-GMO, allergen-free, and feature a neutral taste, making them an excellent addition to baked goods aimed at health-minded consumers. With the growing demand for protein-enriched foods, ETprotein’s offerings can help you cater to this market segment and differentiate your products.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.