Hydrolysis and debittering enhance nutritional and sensory qualities of pea peptides

Explore optimized hydrolysis and debittering of pea protein for health foods, enhancing nutritional value and sensory acceptance with advanced research techniques.

Keywords: Pretreatment; enzymatic hydrolysis; pea peptides; bitterness; antioxidant activity

Abstract

Pea protein, a major leguminous protein, has gained interest for its low allergenic potential and high solubility compared to other plant proteins like soy. The production of small molecular peptides from pea protein, which are easily absorbed by the human body, has been extensively studied for their health benefits including antioxidant, antihypertensive, and anti-inflammatory properties. This research focuses on improving the hydrolysis efficiency of pea protein through pretreatment methods and addressing the challenge of bitterness in hydrolyzed pea protein products, thus optimizing its use in health food applications.

Introduction

Peas are cultivated worldwide and are considered a vital source of plant protein. Unlike soy proteins, pea proteins are less allergenic and possess a rich amino acid profile, making them a favorable alternative in various health food products. However, the hydrolysis process, primarily enzymatic, faces challenges such as low hydrolysis degree and the formation of insoluble aggregates, reducing the bioavailability and nutritional value of the hydrolyzed products. Moreover, the bitter taste produced during hydrolysis limits their acceptance and application in food products. This study aims to optimize the hydrolysis and debittering process of pea proteins to enhance their application in health food products.

Materials and Methods

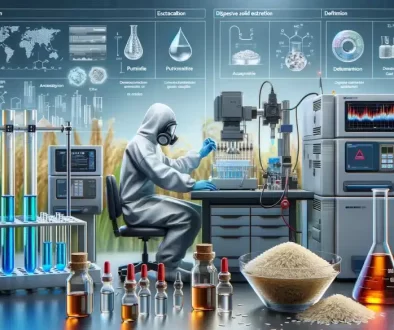

This section details the materials used, including pea protein provided by Jiangsu Ronghai Company, enzymes from Novozymes, and various reagents for assessing the antioxidant activity of pea peptides. The study elaborates on the enzymatic hydrolysis process, pretreatment methods like heat and high-speed shearing, and evaluates the hydrolysis effects. Furthermore, it describes the debittering techniques used, including tert-butanol treatment, flavorzyme treatment, and β-CD addition, and assesses their impact on the sensory quality and antioxidant activity of the pea peptides.

Results and Discussion

Hydrolysis Optimization

The study compared the effects of heat treatment and high-speed shearing on the enzymatic hydrolysis of pea protein, observing improvements in hydrolysis efficiency. The microstructural changes post-pretreatment were analyzed using FTIR and SEM, providing insight into the enhanced hydrolysis.

Debittering Techniques and Sensory Evaluation

Different debittering strategies were evaluated for their effectiveness in reducing the bitterness of hydrolyzed pea peptides. The study found that a combination of tert-butanol and β-CD was most effective in reducing bitterness without significantly impacting the antioxidant activity of the peptides. Sensory evaluation and electronic tongue analysis were conducted to assess the impact of debittering on the taste profile of pea peptides.

Antioxidant Activity

The antioxidant activity of the pea peptides, before and after debittering treatment, was analyzed using DPPH, ABTS, and iron-binding assays. The study highlighted the potential of optimized hydrolyzed pea peptides as a functional ingredient in health foods, given their retained antioxidant properties post-debittering.

Conclusion

This research successfully optimized the enzymatic hydrolysis of pea protein by employing pretreatment methods and developed an effective debittering process that minimizes the bitterness of pea peptides without compromising their antioxidant activity. These findings contribute to the development of pea protein-based health food products with improved nutritional value and sensory acceptance.

For more further detailed information of this research, feel free to contact our team for asssistance.

Original research by Xia Yixuan, Zhang Hui, Hui Ju, Mu Wanmeng (Food Engineering, Jiangnan University, Wuxi 214122)

About ETprotein:

ETprotein, a reputable rice protein Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan protein and plant proteins. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, pumpkin seed protein, sunflower seed protein, mung bean protein, etc. Our offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, cater to a diverse range of industries. We serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

Our specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Our extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample our products, please contact us and email sales(at)ETprotein.com today.