Incorporation of Automation in the Bakery Industry

-

Table of Contents

- Automation Revolution in the Bakery Industry: Enhancing Efficiency and Productivity

- The Rise of Automation in Bakeries

- Benefits of Automation in the Bakery Sector

- Challenges of Implementing Automation

- Statistics Supporting Automation in the Bakery Industry

- Future of Automation in the Bakery Industry

- Conclusion: Embracing Automation for a Competitive Edge

- ETprotein: Enhancing Bakery Products with High-Quality Proteins

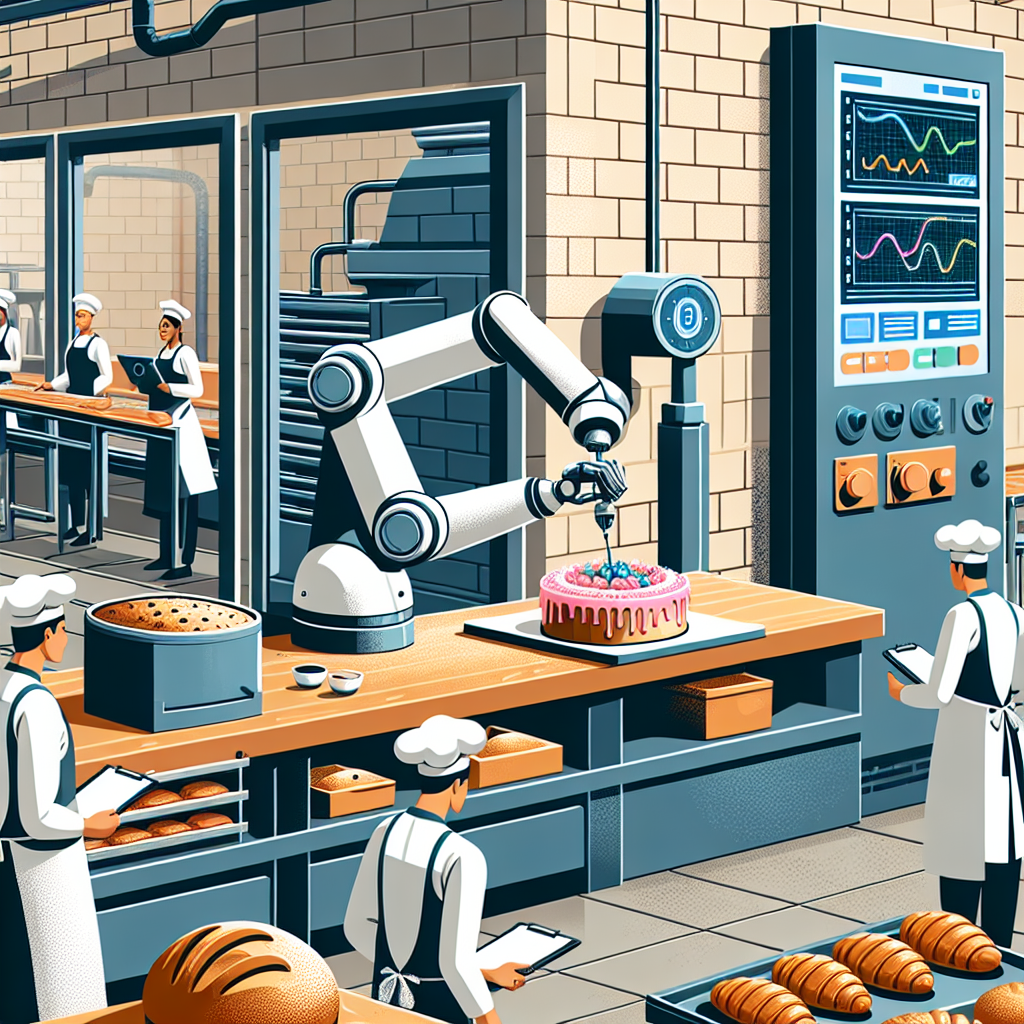

Automation Revolution in the Bakery Industry: Enhancing Efficiency and Productivity

The bakery industry has been undergoing a significant transformation, with automation playing a pivotal role in reshaping production processes. The incorporation of automation in bakeries is not just a trend; it’s a strategic move to enhance efficiency, reduce costs, and improve product consistency. This article delves into the various aspects of automation in the bakery sector, exploring its benefits, challenges, and future prospects.

The Rise of Automation in Bakeries

Automation in the bakery industry has been steadily increasing, driven by the need for higher productivity and the desire to meet the growing demand for baked goods. From mixing ingredients to packaging finished products, automation is becoming an integral part of the bakery production line.

- Automated Mixing and Dough Handling: Machines can now precisely measure ingredients, mix dough, and monitor its development, ensuring consistency and quality.

- Robotic Baking and Cooling: Automated ovens bake large quantities of products uniformly, while robotic systems handle the transfer of goods to cooling conveyors.

- Packaging and Palletizing: Advanced machinery packages baked items with speed and precision, and robotic palletizers prepare products for shipping with minimal human intervention.

Benefits of Automation in the Bakery Sector

Automation brings a host of advantages to the bakery industry, which include:

- Increased Production Speed: Automated systems can operate continuously, significantly increasing output compared to manual processes.

- Consistency and Quality Control: Machines provide uniformity in product size, shape, and quality, enhancing customer satisfaction.

- Labor Cost Reduction: Automation reduces the reliance on skilled labor, which can be costly and difficult to find.

- Improved Safety: Automated equipment minimizes the need for human interaction with potentially hazardous machinery or repetitive tasks that can lead to injury.

- Waste Reduction: Precise ingredient handling and efficient processes lead to less waste, contributing to cost savings and environmental sustainability.

Challenges of Implementing Automation

Despite its benefits, the transition to automation can present several challenges for bakeries:

- High Initial Investment: The cost of purchasing and installing automated equipment can be substantial, especially for small to medium-sized enterprises.

- Technical Expertise: Operating and maintaining automated systems require a certain level of technical knowledge and training.

- Integration with Existing Systems: Integrating new technology with older equipment can be complex and may require additional investment.

- Flexibility Concerns: Some automated systems may lack the flexibility to adapt to new products or changes in production volume.

Statistics Supporting Automation in the Bakery Industry

Recent statistics highlight the impact of automation on the bakery industry:

- According to a report by Meticulous Research, the global bakery processing equipment market is expected to grow at a CAGR of 5.8% from 2020 to 2027.

- A study by PMMI Business Intelligence states that 50% of bakery companies are planning to increase their level of automation in the next 3-5 years.

- The same report indicates that labor savings is the primary driver for automation investments, with 67% of bakery companies citing it as a significant factor.

Future of Automation in the Bakery Industry

The future of automation in the bakery industry looks promising, with ongoing advancements in technology paving the way for even greater efficiency and innovation. Some of the anticipated developments include:

- Artificial Intelligence (AI) and Machine Learning (ML) integration for predictive maintenance and optimization of production processes.

- Advanced robotics capable of more complex tasks, such as decorating cakes or assembling sandwiches.

- Internet of Things (IoT) connectivity for real-time monitoring and control of bakery operations from remote locations.

- 3D printing technology for creating customized baked products on demand.

Conclusion: Embracing Automation for a Competitive Edge

In conclusion, the incorporation of automation in the bakery industry is not just a passing trend but a strategic necessity. It offers numerous benefits, including increased efficiency, consistent product quality, and reduced labor costs. While challenges such as high initial investment and the need for technical expertise exist, the long-term advantages make automation a worthwhile investment for bakeries looking to stay competitive in a rapidly evolving market.

ETprotein: Enhancing Bakery Products with High-Quality Proteins

As the bakery industry continues to innovate with automation, the demand for high-quality ingredients remains paramount. ETprotein offers a range of organic bulk vegan proteins that can enhance the nutritional profile of baked goods. Their non-GMO, allergen-free proteins, including rice, pea, and various seed proteins, are characterized by a neutral taste and high purity levels, making them ideal for a variety of bakery applications.

For bakeries looking to incorporate protein-enriched products into their offerings, ETprotein’s expertise in protein manufacturing and supply can provide the necessary ingredients to meet consumer demands for healthier options. Their commitment to quality and customer service ensures that bakeries can rely on ETprotein for their protein needs as they embrace the automation revolution.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.