Influence of Processing Methods on the Subunits and Functional Properties of Mung Bean Protein

Optimize your recipes with enhanced mung bean protein – discover improved solubility, stability, and nutritional benefits through innovative processing methods.

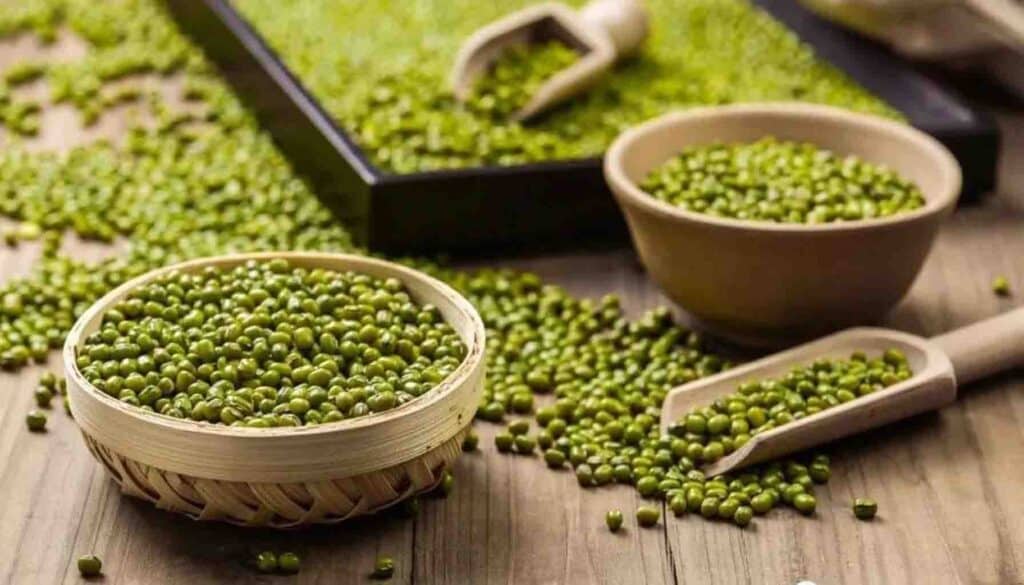

Mung beans, known for their nutritional richness, boast higher protein content compared to other common grains. Mung bean protein is particularly abundant in essential amino acids such as lysine, leucine, and methionine, making it a high-quality plant-based protein. Research indicates that alterations in protein characteristics following heat treatments can significantly impact the flavor and sensory attributes of food products.

Three commonly employed heat processing methods include moist heat, dry heat, and microwave heating. In everyday culinary practices, moist heat methods are predominantly used for mung beans. Studies suggest that judicious heat treatment enhances the solubility, surface properties, water-holding capacity, gelation, and thermal stability of mung bean protein.

This study focuses on protein extraction from mung beans subjected to steaming and boiling, assessing the structural and functional changes in the protein. The objective is to investigate the impact of these moist heat processing methods on the functional properties and structure of mung bean protein, with the aim of determining the optimal processing approach that imparts favorable flavor and functional characteristics in the context of food systems. Such findings hold theoretical significance for the modification of mung bean protein, thereby contributing to its enhanced application in the food industry and the advanced processing of mung bean products.

Isoelectric Point of Mung Bean Protein:

The results reveal that the isoelectric point of untreated mung bean protein is at pH 4.5, where the absorbance is minimized. Steaming and boiling alter the isoelectric point of mung bean protein, affecting the protein extraction process during alkali extraction and acid precipitation. Optimal conditions for protein extraction after heat treatment involve maintaining alkaline pH levels between 9.5 and 10.0 and acidic pH levels between 4.5 and 4.9.

Water-Holding and Oil-Holding Capacity Analysis:

Untreated mung bean protein exhibits a water-holding capacity of 3.4 mL/g. After 30 minutes of processing, the water-holding capacity increases by 23.5% for steamed mung bean protein and 17.6% for boiled mung bean protein. Both processing methods result in continuous improvement in water-holding capacity with prolonged processing time. Although the initial differences are not significant (P > 0.05), a significant disparity emerges after 30 minutes of processing (P < 0.01), with steamed mung bean protein demonstrating superior water-holding capacity compared to boiled mung bean protein.

Similarly, untreated mung bean protein exhibits an oil-holding capacity of 4.0 mL/g. After 30 minutes of processing, the oil-holding capacity increases by 32.5% for steamed mung bean protein and 22.5% for boiled mung bean protein. The difference in oil-holding capacity between the two processing methods remains relatively constant over time, with steamed mung bean protein consistently outperforming boiled mung bean protein (P < 0.05).

Emulsifying and Emulsion Stability Analysis:

The emulsifying capacity and emulsion stability of untreated mung bean protein are 42.3% and 50.1%, respectively. After 30 minutes of processing, steamed mung bean protein exhibits a 19.9% increase in emulsifying capacity and a 20.8% increase in emulsion stability, while boiled mung bean protein shows an 18.9% increase in emulsifying capacity and a 19.0% increase in emulsion stability. Both processing methods result in a consistent upward trend in emulsifying capacity and emulsion stability with prolonged processing time, and steamed mung bean protein consistently surpasses boiled mung bean protein in emulsifying capacity (P < 0.05). Significant differences in emulsion stability between the two processing methods are observed at various time points (P < 0.05), with steamed mung bean protein demonstrating extremely high stability compared to boiling at 20 minutes (P < 0.01).

Foaming and Foam Stability Analysis:

As processing time increases, both foaming capacity and foam stability of mung bean protein for both processing methods initially increase and then decline. Significant differences (P < 0.05) exist between the two processing methods, with boiled mung bean protein exhibiting higher foaming capacity and foam stability than steamed mung bean protein. The properties for both foaming and foam stability reach optimal levels at 25 minutes, with foaming capacity for boiled mung bean protein significantly higher than that of steamed mung bean protein at 25 minutes (P < 0.01). Foam stability shows no significant difference between the two methods at 30 minutes (P > 0.05).

The foaming capacity of untreated mung bean protein is 20.1%, and at 25 minutes of processing, steamed and boiled mung bean proteins exhibit foaming capacities of 25.0% and 25.6%, respectively. Both processing methods result in a 24.4% and 27.4% increase in foaming capacity, with a consistent decline as processing time extends.

Foam stability of untreated mung bean protein is 55.4%, and at 25 minutes of processing, foam stability increases to 75.7% for steamed mung bean protein and 77.1% for boiled mung bean protein. Both methods result in a significant improvement in foam stability by 36.6% and 39.2%, respectively. Overall, boiled mung bean protein outperforms steamed mung bean protein in both properties.

Solubility Analysis:

Both steamed and boiled mung bean protein exhibit a trend of initially increasing and then decreasing solubility with prolonged processing time. At 20 minutes, solubility reaches its peak, with steamed mung bean protein showing a solubility of 13.6% and boiled mung bean protein showing a solubility of 13.2%. Steamed mung bean protein consistently outperforms boiled mung bean protein in solubility after 20 minutes (P < 0.05). Compared to the initial solubility of untreated mung bean protein at 9.8%, solubility increases by 38.8% for steamed mung bean protein and 34.7% for boiled mung bean protein.

Elevate Your Culinary Experience with ETprotein’s Mung Bean Protein

In conclusion, for those seeking a superior mung bean protein, we recommend exploring ETprotein’s innovative offerings. With a commitment to optimizing nutritional content and functional properties, ETprotein’s mung bean protein stands out for its remarkable solubility, stability, and versatility. Elevate your culinary creations with the high-quality protein provided by ETprotein, unlocking a world of enhanced flavor and nutrition for your food industry applications.

Conclusion:

SDS-PAGE analysis reveals that both steaming and boiling result in a reduction of the grayscale intensity of large molecular protein subunits in mung bean protein, indicating a decrease in their content with prolonged heat treatment. As processing time increases, the II subunit band of 8S globulin gradually disappears. Boiling introduces a new band (VI) with a molecular mass of 35.4 kDa, absent in steamed mung bean protein. Functional property studies demonstrate an overall improvement in the functional properties of mung bean protein after processing, surpassing untreated mung bean protein. Compared to untreated mung bean protein, steamed and boiled mung bean protein exhibit increased water-holding capacity by 23.5% and 17.6%, oil-holding capacity by 32.5% and 22.5%, emulsifying capacity by 19.9% and 18.9%, emulsion stability by 20.8% and 19.0%, foaming capacity by 24.4% and 27.4%, foam stability by 36.