Leveraging AI in Cheese Manufacturing: Revolutionizing Productivity and Quality

-

Table of Contents

- Leveraging AI in Cheese Manufacturing: Enhancing Productivity and Quality

- The Role of AI in Modern Cheese Manufacturing

- Improving Productivity with AI

- Ensuring Quality and Consistency

- Case Studies: AI Success Stories in Cheese Manufacturing

- Challenges and Considerations

- Conclusion: The Future of Cheese Manufacturing with AI

- ETprotein’s Contribution to Cheese Manufacturing

Leveraging AI in Cheese Manufacturing: Enhancing Productivity and Quality

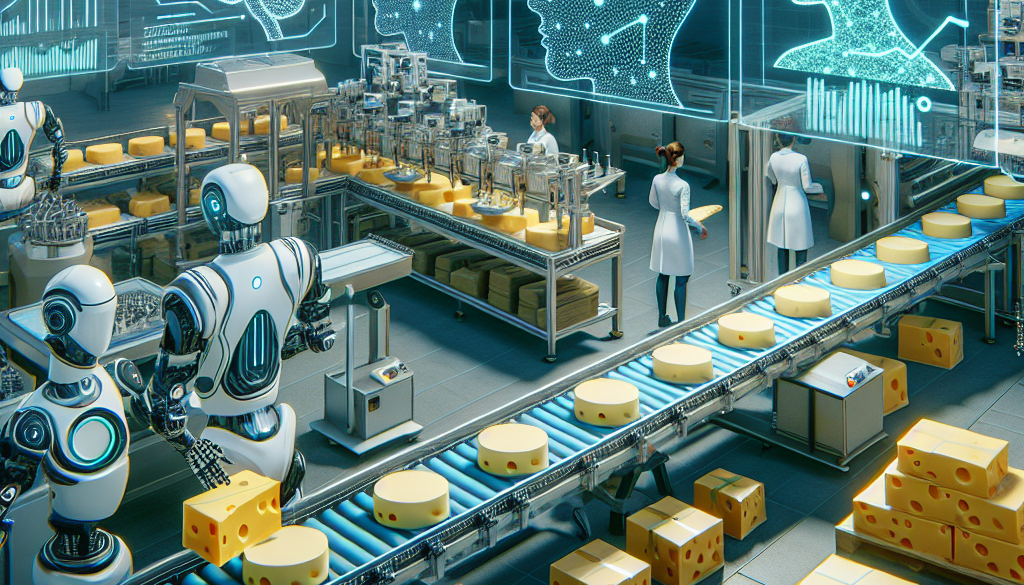

The cheese manufacturing industry is undergoing a significant transformation, thanks to the advent of Artificial Intelligence (AI). AI is revolutionizing the way cheese is produced, from the initial stages of milk processing to the final product packaging. This technological advancement is not only improving productivity and efficiency but also ensuring a higher standard of quality and consistency in cheese products. In this article, we will explore how AI is being leveraged in cheese manufacturing and the benefits it brings to the industry.

The Role of AI in Modern Cheese Manufacturing

AI technology is being integrated into various stages of the cheese-making process. Here are some of the key areas where AI is making an impact:

- Milk Quality Analysis: AI-powered sensors can analyze the quality of milk, which is the fundamental ingredient in cheese production. These sensors detect impurities and composition, ensuring only high-quality milk is used.

- Process Optimization: AI algorithms can optimize cheese production processes by monitoring and adjusting variables such as temperature, pH levels, and humidity to ensure the perfect environment for cheese aging.

- Predictive Maintenance: AI systems can predict when equipment needs maintenance before it breaks down, reducing downtime and increasing productivity.

- Quality Control: Through machine learning and computer vision, AI can inspect and ensure that each cheese product meets stringent quality standards.

- Inventory Management: AI helps in forecasting demand and managing inventory, ensuring that supply meets consumer needs without excessive waste.

Improving Productivity with AI

One of the most significant advantages of AI in cheese manufacturing is the increase in productivity. By automating repetitive tasks, AI allows human workers to focus on more complex aspects of the production process. For instance, robotic arms equipped with AI can handle the cutting and packaging of cheese, which speeds up the process and minimizes human error.

Statistics show that automation can increase production speeds by up to 15%. This increase is crucial in an industry that is experiencing growing demand worldwide. According to the International Dairy Foods Association, cheese consumption has been steadily increasing, with an average American consuming around 40 pounds of cheese annually.

Ensuring Quality and Consistency

Quality is paramount in the cheese industry, and AI is playing a pivotal role in maintaining and improving it. AI systems can analyze the composition of cheese at a molecular level, ensuring that each batch meets the desired flavor, texture, and aroma profiles. This level of consistency is difficult to achieve through manual processes alone.

Moreover, AI-driven data analytics can provide insights into the fermentation process, allowing manufacturers to fine-tune their recipes for optimal results. This precision leads to a higher quality product that meets consumer expectations every time.

Case Studies: AI Success Stories in Cheese Manufacturing

Several cheese manufacturers have already embraced AI to great success. For example, a European cheese producer implemented AI to monitor the ripening of their cheese. The AI system predicted the optimal ripening time, resulting in a 30% reduction in product waste and a significant improvement in cheese quality.

In another instance, a cheese factory in the United States used AI to optimize its production schedule based on real-time demand forecasts. This led to a 20% increase in production efficiency and a reduction in energy costs.

Challenges and Considerations

While the benefits of AI in cheese manufacturing are clear, there are challenges to its implementation. The initial investment in AI technology can be substantial, and there is a learning curve associated with integrating these systems into existing production lines. Additionally, there are concerns about data privacy and the need for skilled personnel to manage and interpret AI data.

Conclusion: The Future of Cheese Manufacturing with AI

AI is set to become an integral part of cheese manufacturing, offering numerous benefits such as increased productivity, improved quality, and enhanced consistency. As technology continues to advance, we can expect even more innovative applications of AI in the industry. The key to successful implementation lies in overcoming the initial challenges and embracing the potential of AI to create a more efficient and sustainable cheese manufacturing process.

ETprotein’s Contribution to Cheese Manufacturing

While AI revolutionizes cheese manufacturing, high-quality protein ingredients remain essential for producing nutritious and delicious cheese products. ETprotein company’s protein products offer manufacturers top-grade, organic, and non-GMO protein solutions that can complement the technological advancements in the industry.

ETprotein’s range of plant-based proteins, including rice, pea, and seed proteins, provide a neutral taste and allergen-free options for cheese production. Their L-(+)-Ergothioneine (EGT) products also offer additional health benefits, making them an excellent choice for cheese manufacturers looking to enhance their products’ nutritional profile.

For more information on how ETprotein can support your cheese manufacturing needs with their high-quality protein products, please contact them at sales(at)ETprotein.com.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.