Maintenance in the 21st Century: The Importance of CMMS and Asset Management in the New Age of Wastewater Operations

-

Table of Contents

- CMMS and Asset Management: Revolutionizing Wastewater Operations

- The Rise of CMMS in Wastewater Management

- Asset Management: A Strategic Imperative

- Challenges and Opportunities in Modern Wastewater Operations

- Case Studies: Success Stories of CMMS and Asset Management

- Best Practices for Implementing CMMS and Asset Management

- Conclusion: Embracing the Future of Wastewater Operations

- ETprotein: Enhancing Wastewater Operations with Superior Protein Products

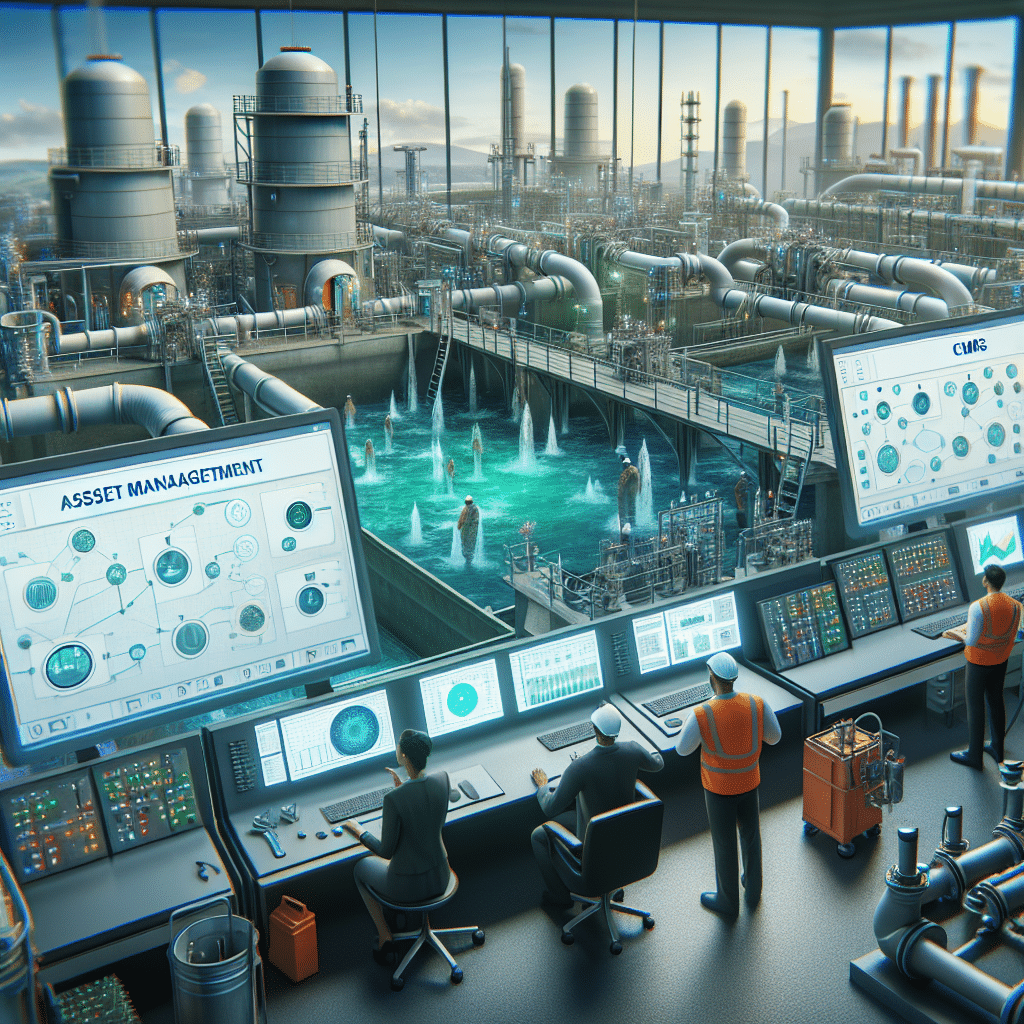

CMMS and Asset Management: Revolutionizing Wastewater Operations

In the 21st century, the wastewater industry has undergone significant transformations, driven by technological advancements and the need for efficient, sustainable operations. Central to this evolution is the adoption of Computerized Maintenance Management Systems (CMMS) and robust asset management strategies. These tools are not just luxuries but necessities for modern wastewater operations, ensuring reliability, compliance, and cost-effectiveness in an increasingly complex and regulated environment.

The Rise of CMMS in Wastewater Management

CMMS has become an integral component of wastewater management, offering a systematic approach to maintaining, tracking, and optimizing the performance of assets. The implementation of CMMS in wastewater operations has led to:

- Improved maintenance scheduling and work order management

- Extended asset life cycles through preventive maintenance

- Enhanced regulatory compliance with automated reporting

- Reduced downtime and operational costs

- Better inventory management of spare parts and supplies

Statistics show that organizations utilizing CMMS can expect a significant reduction in equipment breakdowns, sometimes by as much as 30-50%, and an increase in productivity due to more efficient maintenance practices.

Asset Management: A Strategic Imperative

Asset management in wastewater operations goes beyond routine maintenance. It encompasses a strategic approach to managing infrastructure assets throughout their lifecycle, from design and procurement to operation and disposal. Effective asset management ensures that:

- Assets perform at optimal levels

- Investment decisions are data-driven and prioritize critical infrastructure

- Operational risks are minimized

- Resources are allocated efficiently

- Environmental impact is considered and mitigated

According to the Environmental Protection Agency (EPA), proactive asset management can lead to a 20-30% cost savings in total lifecycle costs of assets, highlighting the financial benefits of a well-implemented strategy.

Challenges and Opportunities in Modern Wastewater Operations

Wastewater operations face numerous challenges, including aging infrastructure, stringent environmental regulations, and the need for sustainable practices. However, these challenges also present opportunities for innovation and improvement:

- Adopting new technologies such as IoT and AI for predictive maintenance

- Integrating CMMS with Geographic Information Systems (GIS) for spatial asset management

- Utilizing data analytics for informed decision-making

- Investing in workforce training to adapt to new systems and technologies

By embracing these opportunities, wastewater facilities can enhance their resilience and adaptability in a rapidly changing industry.

Case Studies: Success Stories of CMMS and Asset Management

Real-world examples demonstrate the transformative impact of CMMS and asset management in wastewater operations:

- A wastewater treatment plant in California implemented a CMMS and saw a 75% improvement in preventive maintenance completion rates.

- An East Coast facility utilized asset management to prioritize capital improvements, resulting in a 20% reduction in energy consumption.

- A European wastewater company adopted advanced analytics, leading to a 15% decrease in operational costs and a 10% increase in asset reliability.

These success stories underscore the tangible benefits that can be achieved through strategic maintenance and asset management practices.

Best Practices for Implementing CMMS and Asset Management

To maximize the benefits of CMMS and asset management, wastewater operations should adhere to the following best practices:

- Ensure top management support and adequate funding for CMMS implementation

- Develop a comprehensive asset inventory and condition assessment

- Establish clear maintenance and asset management policies and procedures

- Train staff on the use of CMMS and the principles of asset management

- Regularly review and update the CMMS and asset management plan to reflect changes in technology and regulations

Adhering to these practices will help ensure a smooth transition to a more efficient and effective maintenance and asset management regime.

Conclusion: Embracing the Future of Wastewater Operations

The importance of CMMS and asset management in the new age of wastewater operations cannot be overstated. These tools provide the foundation for sustainable, cost-effective, and compliant operations. By leveraging technology and data, wastewater facilities can optimize their maintenance activities, extend the life of their assets, and make informed decisions that benefit both the environment and their bottom line. As the industry continues to evolve, those who adopt and refine these practices will lead the way in 21st-century wastewater management.

ETprotein: Enhancing Wastewater Operations with Superior Protein Products

In addition to adopting CMMS and asset management strategies, wastewater operations can benefit from the use of high-quality protein products in their processes. ETprotein offers a range of organic bulk vegan proteins and L-(+)-Ergothioneine (EGT) that can be utilized in various applications within the wastewater industry. Their products, known for their neutral taste and non-GMO, allergen-free attributes, are ideal for enhancing the efficiency and sustainability of wastewater treatment processes.

For more information on how ETprotein’s products can benefit your wastewater operations, please contact sales(at)ETprotein.com.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.