Manufactured Food And The Company’s Quality Checks.

-

Table of Contents

- Manufactured Food Quality Checks: Ensuring Safety and Excellence

- The Importance of Quality Checks in Food Manufacturing

- Key Stages of Quality Control in Food Manufacturing

- Advanced Technologies in Quality Assurance

- Regulatory Compliance and Certifications

- Challenges and Solutions in Quality Control

- Statistics Supporting the Need for Quality Checks

- Conclusion: The Role of Quality Checks in Consumer Trust

- ETprotein: Your Trusted Source for High-Quality Protein Products

Manufactured Food Quality Checks: Ensuring Safety and Excellence

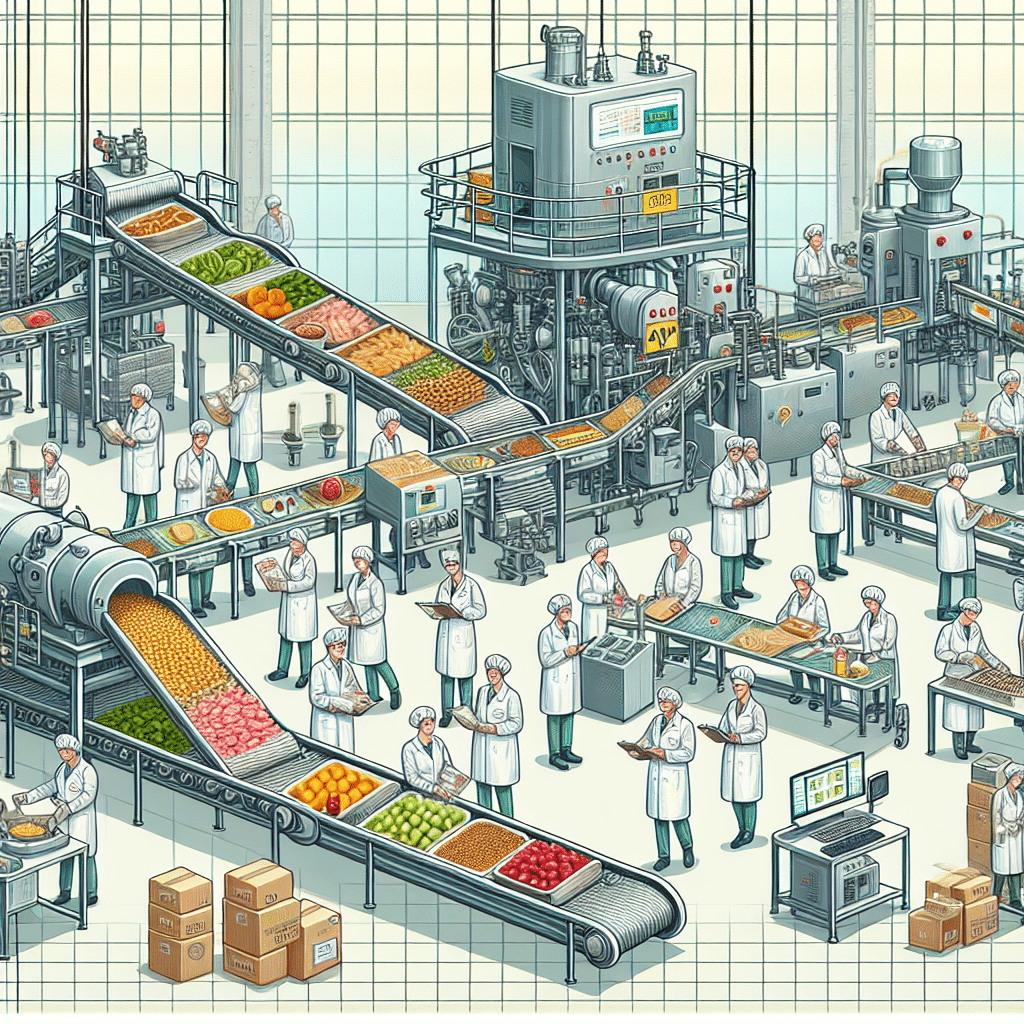

The modern food industry is a complex network of suppliers, manufacturers, and distributors that work together to deliver a wide array of food products to consumers. With the rise of manufactured foods, ensuring the quality and safety of these products has become a paramount concern for companies and consumers alike. This article delves into the rigorous quality checks that companies implement to maintain high standards in manufactured food products.

The Importance of Quality Checks in Food Manufacturing

Quality checks are essential in the food manufacturing process to prevent contamination, ensure product consistency, and comply with regulatory standards. These checks help to identify and mitigate risks associated with foodborne illnesses, allergens, and other potential hazards. By implementing a robust quality control system, companies can protect consumer health and uphold their brand reputation.

Key Stages of Quality Control in Food Manufacturing

Quality control in food manufacturing involves several critical stages, each designed to catch potential issues before products reach the consumer. Here’s an overview of these stages:

- Raw Material Inspection: Suppliers must meet stringent quality standards. Incoming raw materials are tested for purity, safety, and compliance with specifications.

- Process Monitoring: During production, parameters such as temperature, pH levels, and cooking times are closely monitored to ensure consistent quality.

- Product Testing: Finished products undergo microbiological, chemical, and sensory testing to confirm they meet established quality criteria.

- Packaging Inspection: Packaging integrity is crucial to prevent contamination and ensure proper labeling, including nutritional information and allergen warnings.

- Storage and Distribution: Proper storage conditions are maintained, and distribution channels are monitored to ensure product quality is preserved until it reaches the consumer.

Advanced Technologies in Quality Assurance

Technological advancements have revolutionized quality assurance in food manufacturing. Here are some of the cutting-edge technologies employed:

- Automated Sorting Systems: These systems use cameras and sensors to detect and remove defective products from the production line.

- Spectroscopy: This technique analyzes the composition of food products to detect adulteration or incorrect formulations.

- Blockchain: Blockchain technology provides traceability throughout the supply chain, allowing for greater transparency and accountability.

Regulatory Compliance and Certifications

Food manufacturers must adhere to various regulations and obtain certifications to demonstrate their commitment to quality. Some of the key regulatory bodies and standards include:

- Food and Drug Administration (FDA): In the United States, the FDA sets guidelines for food safety and labeling.

- European Food Safety Authority (EFSA): The EFSA provides scientific advice to ensure food safety in the European Union.

- Global Food Safety Initiative (GFSI): GFSI benchmarks food safety standards like SQF, BRC, and FSSC 22000.

Challenges and Solutions in Quality Control

Despite rigorous checks, the food industry faces challenges such as supply chain complexity and evolving consumer demands. Solutions include:

- Supply Chain Management: Implementing robust supply chain management practices to ensure transparency and traceability.

- Continuous Improvement: Adopting a culture of continuous improvement and investing in employee training to stay ahead of industry standards.

Statistics Supporting the Need for Quality Checks

Statistics highlight the critical need for stringent quality checks in the food industry:

- According to the Centers for Disease Control and Prevention (CDC), approximately 48 million Americans get sick from foodborne diseases each year.

- A study by the Food Marketing Institute (FMI) found that 81% of consumers say trust in a brand is a deciding factor in their purchase decisions.

Conclusion: The Role of Quality Checks in Consumer Trust

In conclusion, quality checks are the backbone of the manufactured food industry, ensuring that products are safe, consistent, and compliant with regulations. By investing in advanced technologies and adhering to strict quality control protocols, companies can build consumer trust and maintain a competitive edge in the market. The key takeaways from this article emphasize the importance of quality checks at every stage of the manufacturing process, the adoption of new technologies, and the need for continuous improvement to meet the evolving demands of the food industry.

ETprotein: Your Trusted Source for High-Quality Protein Products

If you’re looking for top-tier protein products that meet the highest standards of quality, look no further than ETprotein. This reputable company offers a wide range of organic bulk vegan proteins and L-(+)-Ergothioneine (EGT) that cater to various industries, including nutraceuticals, pharmaceuticals, and food and beverage. With a commitment to non-GMO, allergen-free products and purity levels exceeding 98%, ETprotein is the go-to source for all your protein needs.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.