Meat Protein Gelling Properties: Understanding the Basics

-

Table of Contents

- Meat Protein Gelling Properties: A Comprehensive Guide

- What Are Meat Protein Gelling Properties?

- Science Behind Meat Protein Gelation

- Factors Influencing Meat Protein Gelation

- Practical Applications of Meat Protein Gels

- Challenges and Innovations in Meat Protein Gelation

- Case Studies and Statistics

- Conclusion: Key Takeaways on Meat Protein Gelling Properties

- Discover ETprotein’s High-Quality Protein Products

Meat Protein Gelling Properties: A Comprehensive Guide

Understanding the gelling properties of meat proteins is crucial for the food industry, particularly in the production of processed meat products. The ability of meat proteins to form gels affects the texture, mouthfeel, and overall quality of food items such as sausages, hams, and canned meats. This article delves into the basics of meat protein gelling properties, exploring the science behind it, factors influencing gelation, and its practical applications.

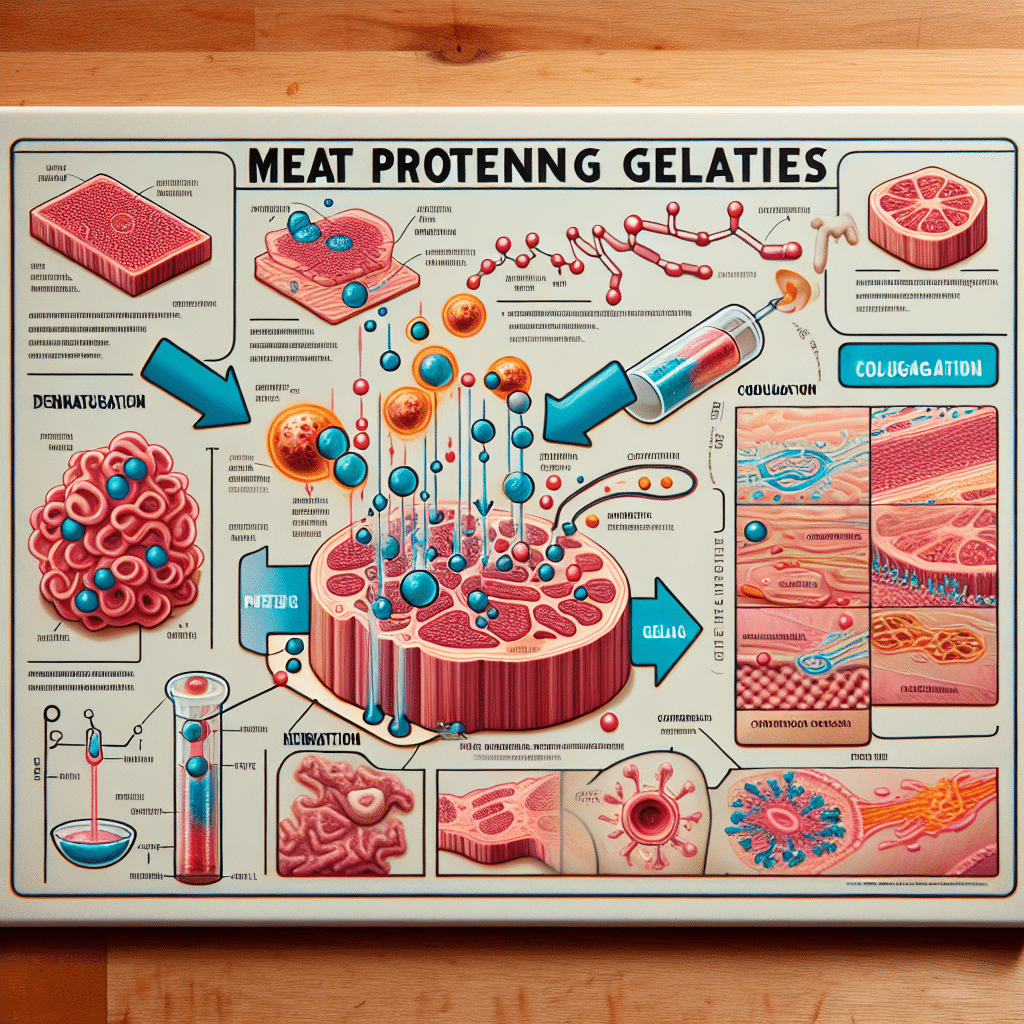

What Are Meat Protein Gelling Properties?

Meat protein gelling properties refer to the ability of proteins, primarily myosin and actin, to undergo a transformation from a sol (liquid) state to a gel (semi-solid) state. This process is essential in creating the desired texture and structural integrity in many meat products. The gelation process involves protein denaturation followed by aggregation, resulting in a three-dimensional network that traps water and fat, contributing to the product’s final texture.

Science Behind Meat Protein Gelation

The gelation of meat proteins is a complex process that can be broken down into two main stages: denaturation and aggregation. Denaturation involves the unfolding of protein structures, which exposes hydrophobic residues that were previously buried within the protein. This change in structure is typically induced by factors such as heat, mechanical action, or the addition of salts. Following denaturation, the proteins aggregate to form a network, which is stabilized by various bonds and interactions, including hydrogen bonds, ionic bonds, and hydrophobic interactions.

Factors Influencing Meat Protein Gelation

Several factors can affect the gelling properties of meat proteins, including:

- Protein Concentration: Higher protein concentrations generally lead to stronger gels due to increased interaction between protein molecules.

- Temperature: The rate and extent of denaturation and aggregation are significantly influenced by temperature. Optimal temperatures for gelation vary depending on the specific protein.

- pH: The pH level can alter the net charge on protein molecules, affecting their ability to interact and form gels.

- Salts and Additives: The presence of salts and other additives can enhance or inhibit gelation by affecting protein solubility and interaction.

- Meat Processing: Mechanical actions such as chopping and mixing can influence the gelation process by altering protein structure and distribution.

Practical Applications of Meat Protein Gels

Meat protein gels are widely used in the food industry to create a variety of products. For example:

- Sausages: The gelling properties of meat proteins help to bind the meat particles together, providing the characteristic firmness and sliceability of sausages.

- Ham: In the production of ham, protein gels contribute to the water-binding capacity, ensuring the product remains moist and tender.

- Canned Meats: Protein gels are essential for maintaining the structural integrity of canned meats during the sterilization process.

Challenges and Innovations in Meat Protein Gelation

Despite its widespread use, there are challenges associated with meat protein gelation, such as variability in raw materials and the need for clean label solutions. Innovations in this field are focused on improving the consistency and quality of gels while reducing reliance on synthetic additives. For instance, the use of natural ingredients like plant extracts and fibers as gel enhancers is gaining popularity.

Case Studies and Statistics

Research and industry case studies have demonstrated the importance of optimizing meat protein gelling properties. For example, a study on the effects of salt reduction in meat products showed that while lower salt levels can negatively impact gel strength, the addition of certain ingredients like xanthan gum can compensate for this effect. Statistics from the meat processing industry highlight the ongoing efforts to improve the textural properties of products, with a significant portion of research and development resources dedicated to understanding and manipulating protein gels.

Conclusion: Key Takeaways on Meat Protein Gelling Properties

In summary, meat protein gelling properties play a pivotal role in the texture and quality of processed meat products. Understanding the science behind gelation, the factors that influence it, and the practical applications is essential for food scientists and industry professionals. Innovations in this area continue to evolve, focusing on natural solutions and improved processing techniques to meet consumer demands for high-quality, clean label products.

Discover ETprotein’s High-Quality Protein Products

If you’re in the food industry and looking for premium protein ingredients, ETprotein offers a range of organic bulk vegan protein and plant proteins that could enhance your product offerings. Their proteins are known for their neutral taste and non-GMO, allergen-free attributes, making them suitable for a variety of applications, including meat analogs and enhancements for meat products.

About ETprotein:

ETprotein, a reputable protein Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan protein and plant proteins. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein etc. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.