Optimising Yeast Recovery in Commercial Breweries

-

Table of Contents

- Optimizing Yeast Recovery in Commercial Breweries: Best Practices

- Understanding the Importance of Yeast Recovery

- Best Practices for Yeast Recovery

- Yeast Harvesting Techniques

- Yeast Storage and Handling

- Yeast Propagation

- Monitoring Yeast Health

- Yeast Washing and Rehydration

- Technological Advances in Yeast Recovery

- Case Studies and Statistics

- Conclusion: The Benefits of Optimized Yeast Recovery

- Enhance Your Brewing with ETprotein’s High-Quality Protein Products

Optimizing Yeast Recovery in Commercial Breweries: Best Practices

Yeast is a critical component in the brewing process, responsible for fermentation and contributing significantly to the flavor profile of beer. In commercial breweries, optimizing yeast recovery is not only a matter of quality but also of economic efficiency. This article explores the best practices for maximizing yeast recovery in commercial brewing operations, ensuring consistent quality while reducing costs.

Understanding the Importance of Yeast Recovery

Yeast recovery refers to the process of collecting, storing, and reusing yeast from one batch of beer to ferment subsequent batches. This practice is essential for several reasons:

- Cost Savings: Reusing yeast reduces the need to purchase new yeast strains, which can be expensive.

- Consistency: Reusing yeast from a successful batch can help maintain the beer’s flavor profile and quality.

- Sustainability: It minimizes waste and supports environmentally friendly brewing practices.

However, improper handling and recovery can lead to contamination, poor beer quality, and inconsistent results. Therefore, it’s crucial to optimize the yeast recovery process.

Best Practices for Yeast Recovery

To optimize yeast recovery, breweries should focus on the following areas:

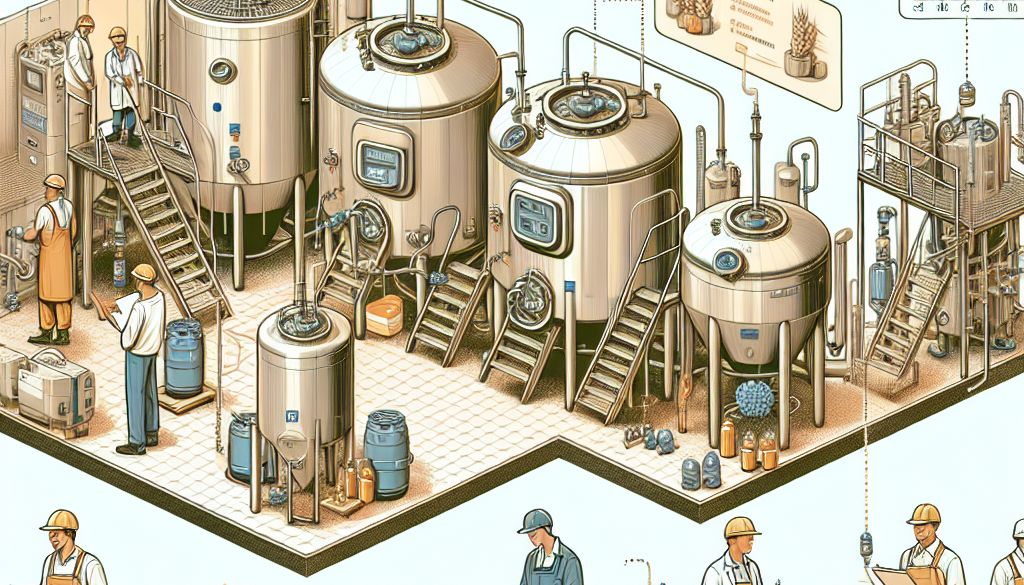

Yeast Harvesting Techniques

Harvesting yeast at the right time and in the right manner is vital. The two common methods are top cropping and bottom cropping. Top cropping involves skimming yeast from the top of the fermenter, typically used with ale yeast strains. Bottom cropping is the collection of yeast that settles at the bottom of the fermenter, common with lager strains.

Yeast Storage and Handling

Once harvested, yeast must be stored under optimal conditions to maintain viability. This includes:

- Temperature Control: Yeast should be stored at consistent, low temperatures to slow down metabolism and preserve cell health.

- Sanitation: Storage vessels must be sanitized to prevent contamination.

- Oxygen Exposure: Minimizing oxygen exposure reduces the risk of oxidative damage to yeast cells.

Yeast Propagation

For larger breweries or those looking to scale up, yeast propagation systems can be a valuable investment. These systems allow for the controlled growth of yeast, ensuring a healthy and robust culture for each batch.

Monitoring Yeast Health

Regular analysis of yeast viability and vitality is crucial. This can be done through:

- Microscopy: Checking for cell shape and size to assess health.

- Viability Stains: Using stains like methylene blue to determine live versus dead cells.

- Fermentation Tests: Small-scale fermentation to ensure yeast performance.

Yeast Washing and Rehydration

Yeast washing is a process used to clean yeast of trub and hop particles, while rehydration is necessary for dried yeast. Both processes must be done carefully to avoid damaging the cells.

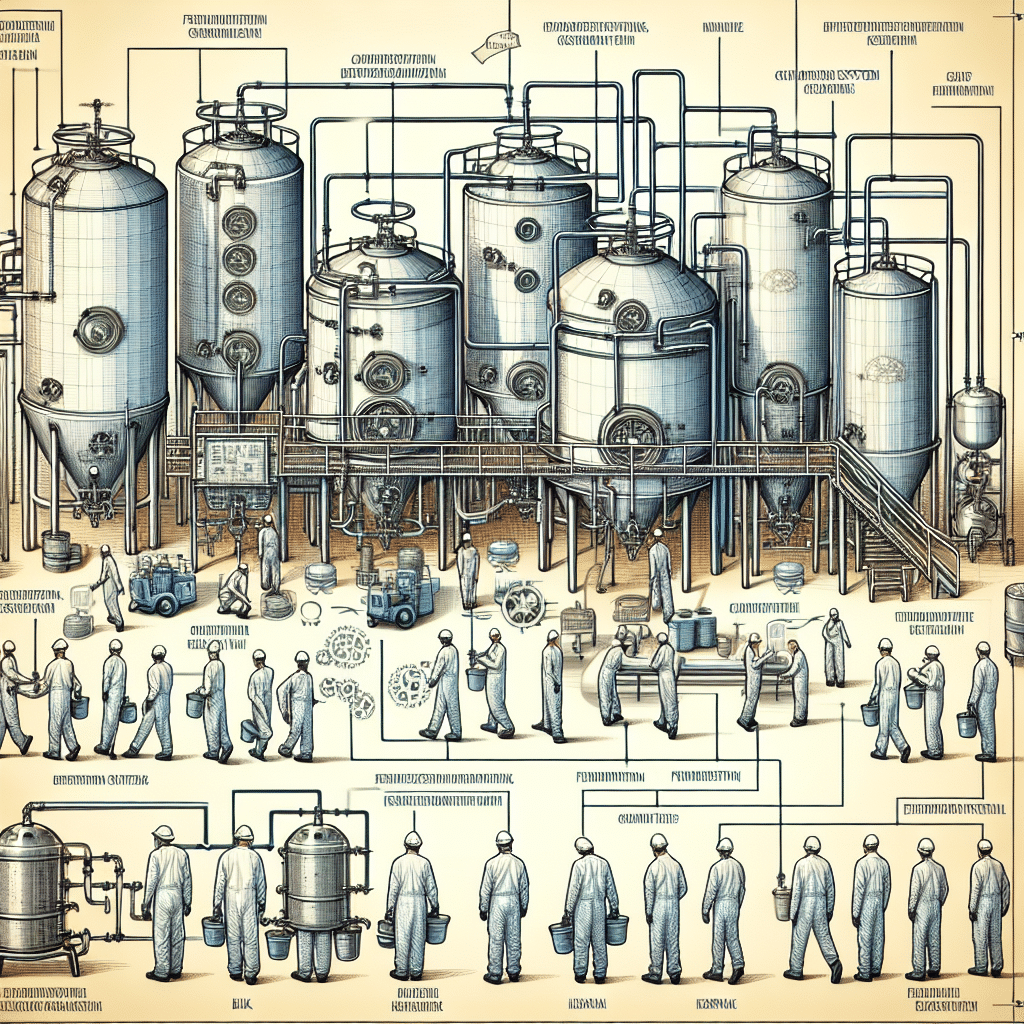

Technological Advances in Yeast Recovery

Advancements in technology have led to more efficient yeast recovery methods. Centrifugation, for example, allows for the rapid separation of yeast from beer, resulting in a cleaner harvest. Membrane filtration is another method gaining popularity due to its ability to selectively recover yeast while removing impurities.

Case Studies and Statistics

Several breweries have reported significant cost savings and improved beer quality after optimizing their yeast recovery processes. For instance, a study published in the Journal of the Institute of Brewing demonstrated that with proper yeast management, breweries could achieve a 70-80% reduction in yeast-related costs. Additionally, breweries that implement rigorous yeast monitoring and handling protocols often see a decrease in batch-to-batch variability, ensuring a consistent product for consumers.

Conclusion: The Benefits of Optimized Yeast Recovery

In conclusion, optimizing yeast recovery is a multifaceted process that requires attention to harvesting, storage, handling, propagation, and monitoring. By implementing best practices in these areas, breweries can achieve significant cost savings, maintain product consistency, and support sustainable brewing operations. The key takeaways for breweries looking to optimize their yeast recovery processes include:

- Choosing the right harvesting technique for the yeast strain used.

- Maintaining strict sanitation and storage conditions.

- Investing in technology that enhances yeast recovery and monitoring.

- Regularly assessing yeast health to ensure high-quality fermentation.

By focusing on these aspects, breweries can not only improve their bottom line but also enhance the overall quality of their beer, satisfying both business objectives and consumer expectations.

Enhance Your Brewing with ETprotein’s High-Quality Protein Products

While optimizing yeast recovery is crucial for brewing operations, it’s also important to consider the quality of other ingredients used in the process. ETprotein offers a range of high-quality protein products that can complement your brewing ingredients, ensuring a superior end product. Their organic bulk vegan proteins and L-(+)-Ergothioneine are perfect for breweries looking to innovate and improve their offerings. Contact ETprotein to explore how their products can benefit your brewery.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.