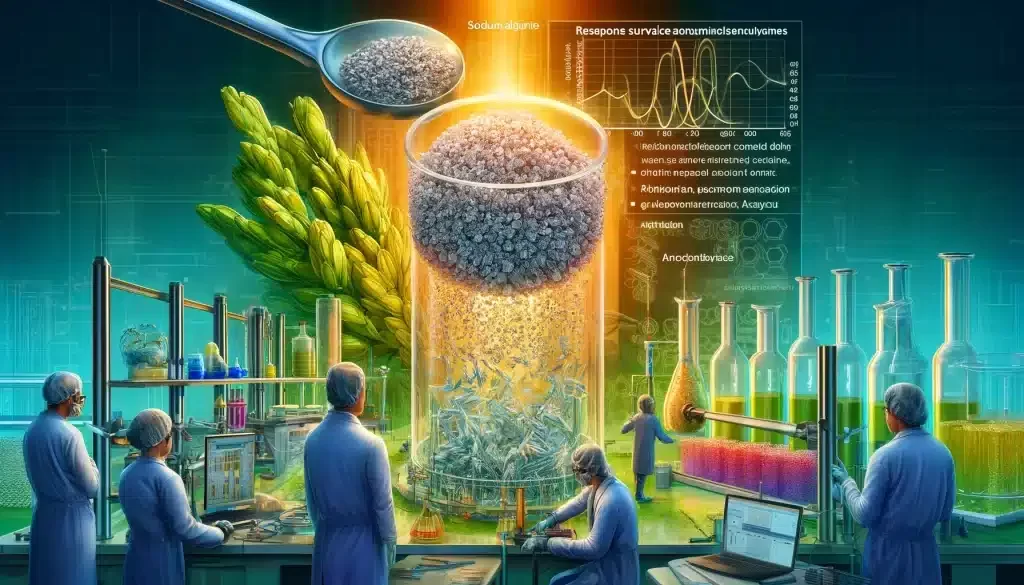

Optimization Of The Process Of Preparing Rice Antioxidant Peptide Microcapsules By Orifice Method Using Response Surface Methodology

Exploring microencapsulation’s efficacy in enhancing rice antioxidant peptide stability using sodium alginate, optimized conditions, and significant results from storage and structural analysis.

In order to improve the stability of rice antioxidant peptides, sodium alginate was used as the wall material and the orifice method was used to microencapsulate the rice antioxidant peptides. Taking the embedding rate as the inspection index, based on the single factor experiment, the response surface analysis method was further used to analyze the mass ratio of the core material to the wall material, the mass fraction of sodium alginate, the embedding temperature, the mass fraction of CaCl2, and the mass fraction of sucrose fatty acid esters. The process conditions were analyzed and optimized, and the prepared microcapsules were subjected to storage experiments and electron microscope scanning. The results of the response surface optimization test show that the optimal process conditions for preparing rice antioxidant peptide microcapsules are the mass ratio of core material to wall material 0.3:1, sodium alginate mass fraction 1.4%, embedding temperature 50¡ãC, and CaCl2 mass fraction 1.8% , the mass fraction of sucrose fatty acid ester is 0.26%. It has been verified that the embedding rate of microcapsules prepared under the above optimal conditions is 81.24%. Compared with the model prediction value of 81.75%, the relative error is only 0.6%. The storage experiment results showed that the stability of the antioxidant peptides in the microcapsules was significantly improved; the scanning electron microscope results showed that the surface morphology and structure of the microcapsules were intact. Experimental results show that microencapsulation is a better method to protect the activity of antioxidant peptides, and can provide a reference for the actual production of rice antioxidant peptide microcapsules.

For futher details of this article and research, feel free to contact our team for assistance.

Original research was done by Zhang Yu, Lin Qinlu, Tan Yicheng, Chen Li

About ETprotein:

ETprotein, a reputable plant protein vegan protein Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan protein and plant proteins. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, oat protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, various of plant peptides etc. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to get a free sample of their protein products, please contact them and email sales(at)ETprotein.com today.