Peanut Process: From Shell to Shelf

-

Table of Contents

- Peanut Process: From Shell to Shelf – A Comprehensive Guide

- The Life Cycle of a Peanut

- Harvesting and Initial Processing

- Shelling and Grading

- Cleaning and Roasting

- Further Processing and Quality Control

- Packaging and Distribution

- Environmental and Economic Impact

- Conclusion: The Journey of Peanuts

- Discover ETprotein’s High-Quality Protein Products

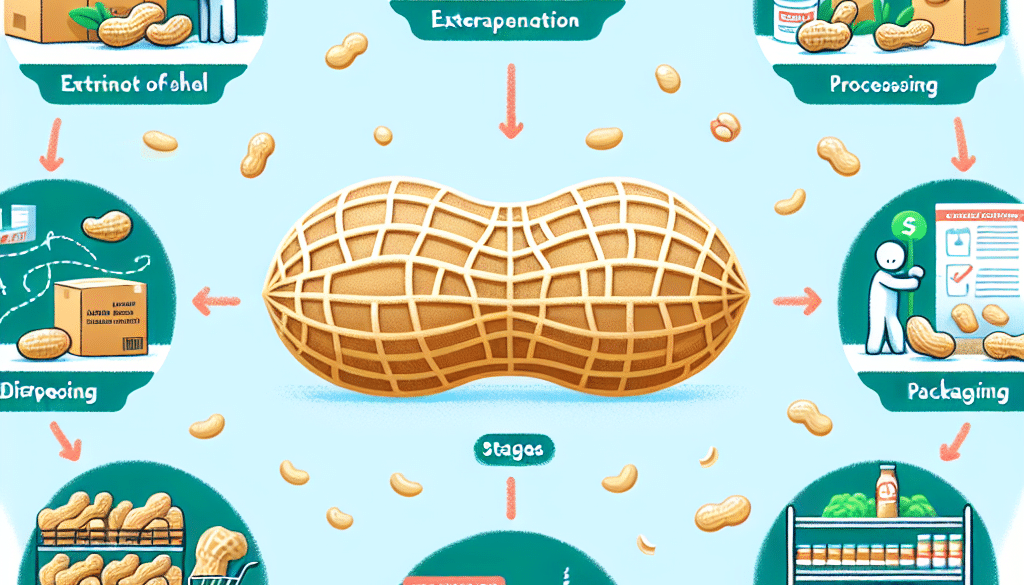

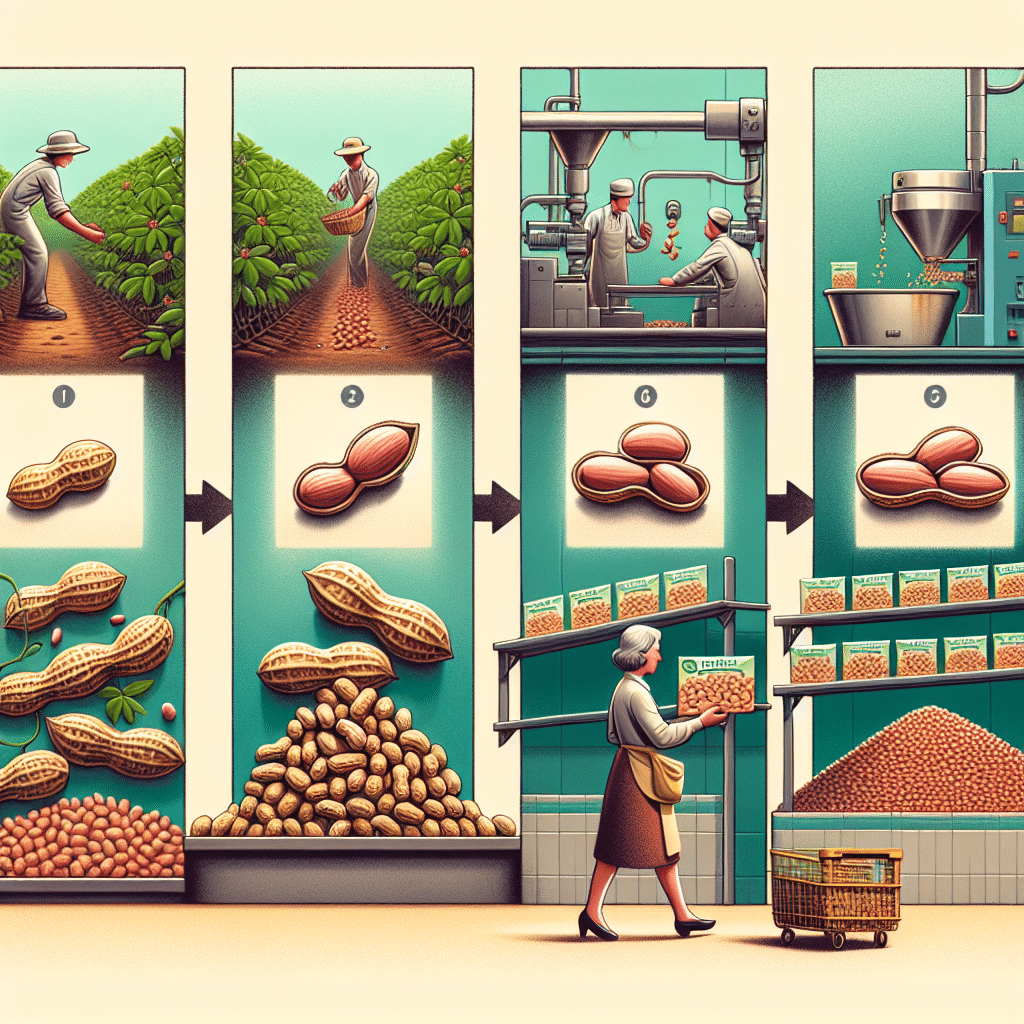

Peanut Process: From Shell to Shelf – A Comprehensive Guide

Peanuts, also known as groundnuts, are not just a popular snack but also a significant agricultural commodity used in a variety of products from peanut butter to cooking oil. The journey of peanuts from being harvested in the fields to reaching the consumer’s shelf is a fascinating and complex process that involves several steps to ensure quality and safety. In this article, we will explore the peanut process in detail, providing valuable insights into how this beloved nut makes its way to your table.

The Life Cycle of a Peanut

Before delving into the processing stages, it’s important to understand the life cycle of a peanut. Peanuts are unique because they flower above the ground, but the peanuts themselves develop below the surface. The life cycle of a peanut plant can be broken down into the following stages:

- Planting: Peanut seeds are planted in sandy soil and warm weather, typically in April or May.

- Growth: The plants grow and flower over the next few months, with the flowers eventually wilting and the peanut pods developing underground.

- Harvesting: Peanuts are typically harvested from August to October, depending on the climate and peanut variety.

Harvesting and Initial Processing

The harvesting of peanuts is a critical step that sets the stage for the quality of the final product. Modern machinery is used to dig up the peanut plants, shake off the excess soil, and invert the plants to allow the peanuts to dry. After drying in the field for a few days, peanuts are collected and transported to processing facilities.

Shelling and Grading

Once at the processing plant, peanuts undergo shelling, where mechanical equipment removes the outer shells without damaging the kernels. The shelled peanuts are then graded based on size, shape, and quality. This grading process is crucial as it determines the peanuts’ end use, whether for direct consumption, oil production, or as an ingredient in other products.

Cleaning and Roasting

After grading, peanuts are thoroughly cleaned to remove any remaining dirt, debris, or foreign materials. The cleaned peanuts can be sold raw or roasted. Roasting enhances the flavor and can be done at various temperatures and durations, depending on the desired taste and color.

Further Processing and Quality Control

Depending on their intended use, peanuts may undergo additional processing such as blanching, which removes the skins, or they may be ground into peanut butter. Throughout the entire process, strict quality control measures are in place to ensure the peanuts meet safety standards. This includes testing for aflatoxins, naturally occurring toxins produced by certain molds that can contaminate peanuts under specific conditions.

Packaging and Distribution

Once processed, peanuts are packaged in various forms, from vacuum-sealed bags to jars of peanut butter. The packaging is designed to protect the product and extend its shelf life. The packaged peanuts are then distributed through various channels to reach retailers and ultimately, consumers.

Environmental and Economic Impact

The peanut industry has a significant environmental and economic impact. Peanuts are a sustainable crop, requiring less water than many other nuts and contributing to soil health through nitrogen fixation. Economically, peanuts are a vital crop for many farmers around the world, providing income and supporting livelihoods.

Conclusion: The Journey of Peanuts

The journey of peanuts from shell to shelf is a testament to the intricate processes involved in bringing agricultural products to market. From careful cultivation and harvesting to meticulous processing and quality control, each step is crucial in ensuring that the peanuts that end up on store shelves are safe, delicious, and ready to be enjoyed by consumers around the world.

Discover ETprotein’s High-Quality Protein Products

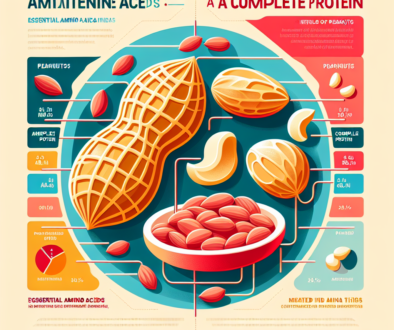

If you’re interested in incorporating high-quality protein into your diet or products, consider ETprotein’s range of protein offerings. ETprotein specializes in organic bulk vegan protein and plant proteins, including peanut protein, which is an excellent source of plant-based nutrition. Their products are non-GMO, allergen-free, and characterized by a neutral taste, making them suitable for a wide range of applications in the food and beverage industry.

About ETprotein:

ETprotein, a reputable protein Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan protein and plant proteins. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein etc. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.