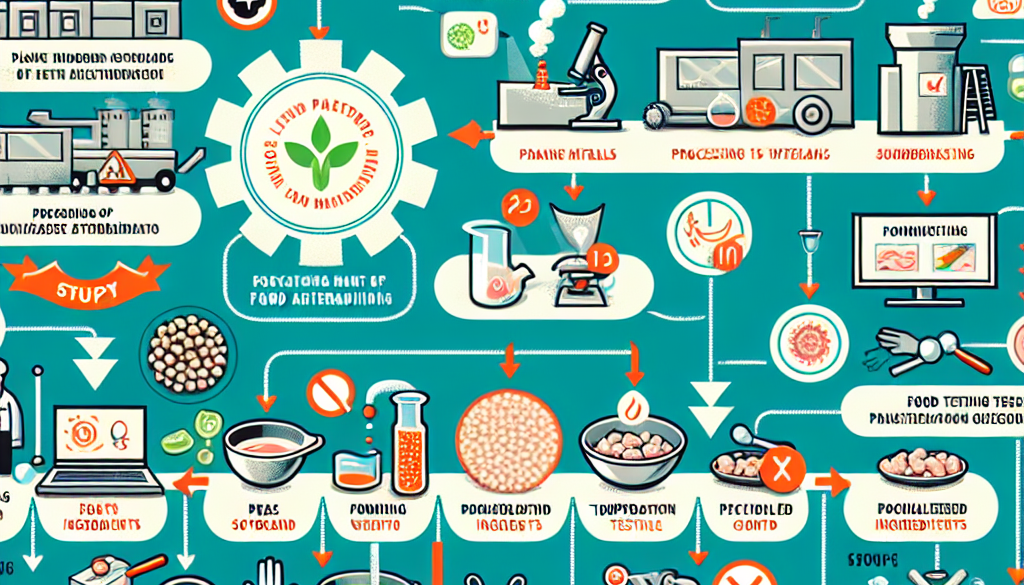

Plant-Based Meat Alternatives: Manufacturing Food Safety Considerations

-

Table of Contents

- Plant-Based Meat Alternatives: Ensuring Food Safety in Manufacturing

- Understanding Plant-Based Meat Alternatives

- Food Safety Challenges in Plant-Based Meat Production

- Key Manufacturing Food Safety Considerations

- Ingredient Sourcing and Traceability

- Facility Design and Hygiene

- Process Control and Validation

- Employee Training and Culture

- Quality Assurance and Testing

- Regulatory Compliance

- Statistics Supporting the Importance of Food Safety

- Conclusion: The Imperative of Food Safety in Plant-Based Meat Manufacturing

- ETprotein: Your Trusted Source for High-Quality Plant Proteins

Plant-Based Meat Alternatives: Ensuring Food Safety in Manufacturing

The rise of plant-based meat alternatives has been meteoric in recent years, driven by consumer demand for sustainable, ethical, and healthier options. As the market for these products grows, so does the importance of food safety in their manufacturing. Ensuring the safety of plant-based meats is crucial, not only for consumer health but also for the credibility and longevity of the industry. This article delves into the key considerations manufacturers must address to maintain the highest standards of food safety.

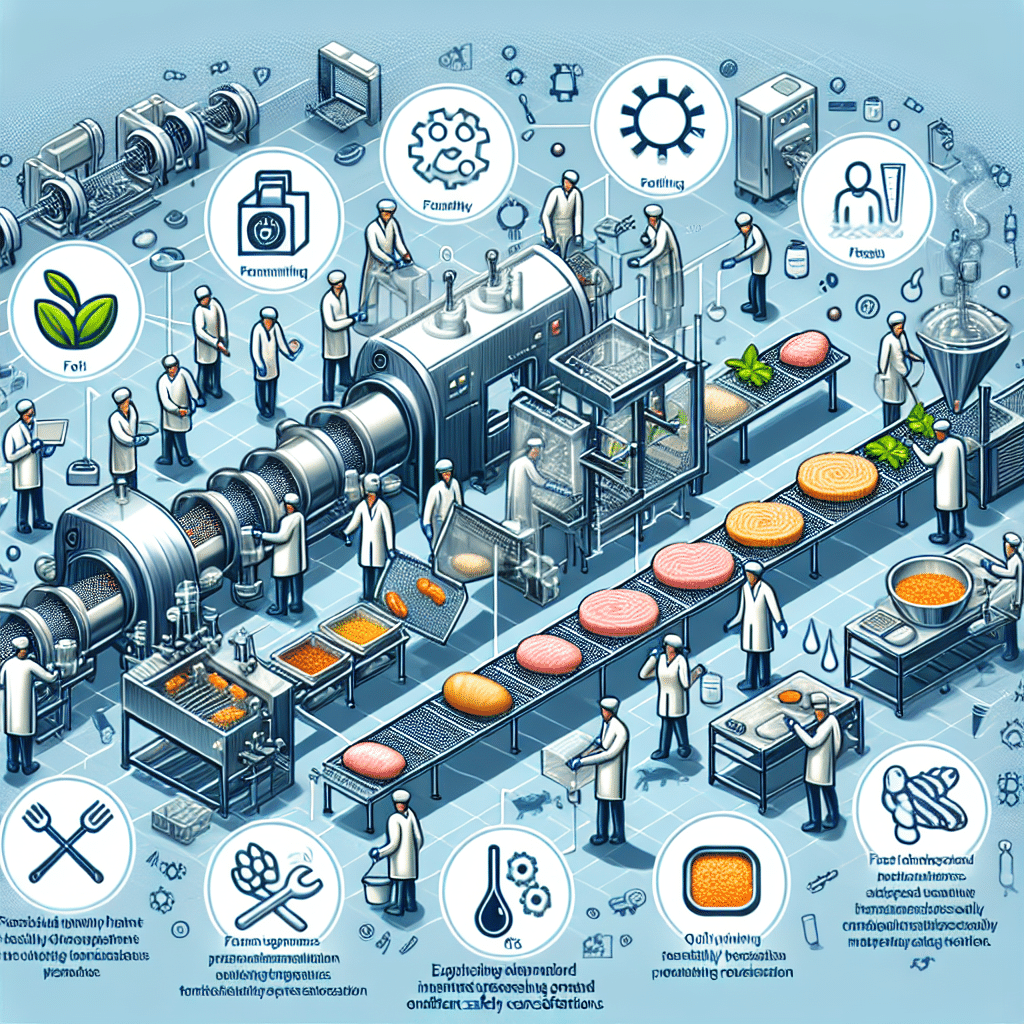

Understanding Plant-Based Meat Alternatives

Plant-based meat alternatives are products designed to mimic the taste, texture, and nutritional profile of animal meat, using plant-derived ingredients. Common sources of protein in these products include soy, peas, and other legumes, as well as grains like wheat and rice. The manufacturing process often involves extrusion, where ingredients are cooked under high pressure and temperature to achieve the desired meat-like consistency.

Food Safety Challenges in Plant-Based Meat Production

The production of plant-based meats presents unique food safety challenges that must be carefully managed:

- Cross-Contamination: Facilities that process both plant-based and animal-based products must prevent cross-contamination.

- Allergen Management: Many plant-based proteins come from allergenic sources, such as soy and nuts, necessitating strict allergen control measures.

- Microbial Risks: Plant-based ingredients can harbor pathogens, making microbial control a top priority.

- Quality Control: Consistency in ingredient quality is vital to ensure the safety and integrity of the final product.

Key Manufacturing Food Safety Considerations

Manufacturers of plant-based meat alternatives must address several critical areas to ensure food safety:

Ingredient Sourcing and Traceability

Securing high-quality ingredients from reputable suppliers is the first step in ensuring food safety. Manufacturers should implement a robust traceability system to track ingredients from farm to final product, enabling quick action in the event of a food safety issue.

Facility Design and Hygiene

Facilities should be designed to minimize the risk of contamination, with dedicated areas for handling allergens and separate lines for plant-based and animal-based products if both are processed. Strict hygiene protocols, including regular cleaning and sanitation, are essential.

Process Control and Validation

Manufacturers must validate their processes to ensure they effectively eliminate or reduce potential pathogens. This includes validating cooking temperatures and times during the extrusion process.

Employee Training and Culture

Employees should be well-trained in food safety practices, and a culture of safety should be fostered throughout the organization. Ongoing education and clear communication are key to maintaining high standards.

Quality Assurance and Testing

Regular testing for contaminants and pathogens is crucial. Quality assurance programs should include both in-house and third-party testing to verify the safety of the products.

Regulatory Compliance

Manufacturers must stay up-to-date with local and international food safety regulations and ensure compliance to avoid recalls and protect consumers.

Statistics Supporting the Importance of Food Safety

Recent statistics highlight the importance of food safety in the plant-based meat industry:

- According to a report by MarketsandMarkets, the global plant-based meat market size is projected to grow from USD 4.3 billion in 2020 to USD 8.3 billion by 2025, at a CAGR of 14.0% during the forecast period.

- A survey by the International Food Information Council (IFIC) found that 63% of consumers say it is important that the foods they purchase and consume are produced in a sustainable way, which includes safe manufacturing practices.

Conclusion: The Imperative of Food Safety in Plant-Based Meat Manufacturing

In conclusion, as the plant-based meat industry continues to expand, manufacturers must prioritize food safety to protect consumers and build trust in these innovative products. By focusing on ingredient sourcing, facility hygiene, process control, employee training, quality assurance, and regulatory compliance, manufacturers can ensure that their plant-based meats are not only delicious and sustainable but also safe for consumption.

ETprotein: Your Trusted Source for High-Quality Plant Proteins

If you’re in the market for top-tier plant-based proteins to create safe and nutritious meat alternatives, ETprotein is your go-to supplier. Their extensive range of organic, non-GMO, allergen-free proteins, including rice, pea, and various seed proteins, meets the highest standards of purity and quality. With a commitment to excellence and customer satisfaction, ETprotein is the ideal partner for your plant-based meat manufacturing needs.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.