Popularity Of Robotics In Food Manufacturing.

-

Table of Contents

- Robotics Revolutionizing Food Manufacturing: Trends and Insights

- The Rise of Robotics in Food Manufacturing

- Statistics Supporting the Robotics Trend

- Applications of Robotics in Food Manufacturing

- Challenges and Solutions

- Future Prospects

- Conclusion: Embracing the Robotic Era in Food Manufacturing

- ETprotein: Your Partner for High-Quality Protein Products

Robotics Revolutionizing Food Manufacturing: Trends and Insights

The food manufacturing industry is undergoing a significant transformation, with robotics playing a pivotal role in reshaping production processes. The integration of robotics in food manufacturing is not just a trend; it’s a necessity driven by the demand for efficiency, consistency, and hygiene. This article delves into the reasons behind the growing popularity of robotics in food manufacturing, supported by statistics and insights that highlight the impact of this technological advancement.

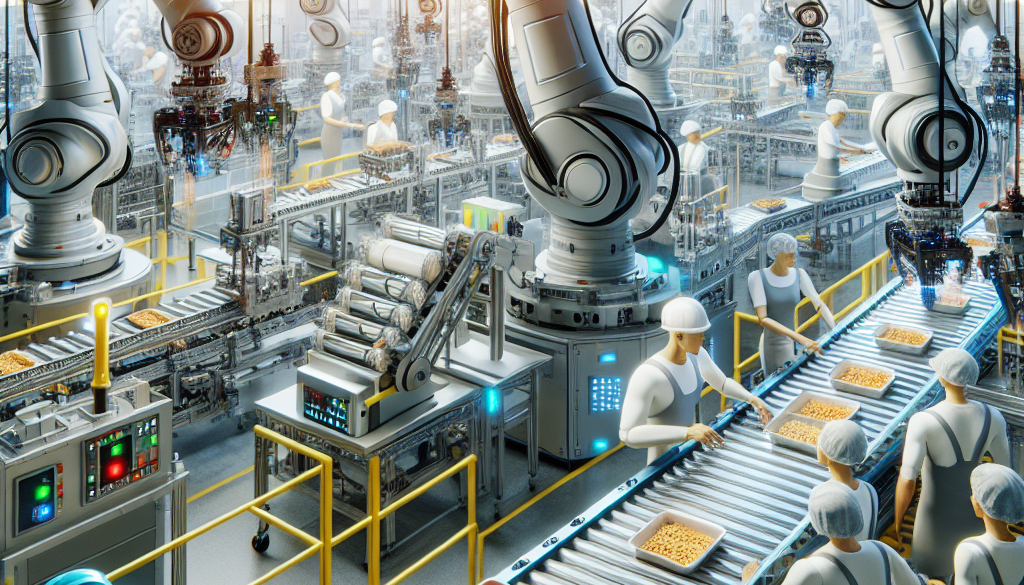

The Rise of Robotics in Food Manufacturing

Robotics has been steadily gaining ground in the food manufacturing sector due to its ability to address several industry challenges. The following points illustrate the key factors contributing to the popularity of robotics:

- Enhanced Productivity: Robots can operate 24/7 without the need for breaks, leading to a significant increase in production rates.

- Improved Precision and Consistency: Robotics technology ensures precise measurements and consistent product quality, which is crucial in food manufacturing.

- Food Safety and Hygiene: Robots minimize human contact with food, thereby reducing the risk of contamination and ensuring higher hygiene standards.

- Labor Shortages: With the ongoing challenge of finding skilled labor, robots offer a reliable solution to fill the gap in the workforce.

- Cost Savings: Over time, the investment in robotics can lead to cost savings by reducing labor costs and increasing efficiency.

Statistics Supporting the Robotics Trend

Recent statistics underscore the growing adoption of robotics in the food manufacturing industry:

- According to a report by the Association for Advancing Automation, robot orders in the food and consumer goods industry increased by 56% in the first quarter of 2021 compared to the previous year.

- The global food robotics market is projected to reach USD 3.1 billion by 2025, growing at a CAGR of 12.7% from 2020 to 2025 (MarketsandMarkets).

- A study by PMMI, The Association for Packaging and Processing Technologies, revealed that 94% of food manufacturers are using or considering using robotics in their operations.

Applications of Robotics in Food Manufacturing

Robotics technology is being utilized in various stages of food production, from processing to packaging. Here are some of the key applications:

- Sorting and Grading: Robots equipped with vision systems can sort and grade products based on size, color, and quality at high speeds.

- Packaging and Palletizing: Robotic arms can package products with precision and stack them onto pallets for distribution, optimizing space and reducing damage.

- Food Processing: From cutting and slicing to mixing and assembling, robots can handle a range of processing tasks with consistency.

- Quality Control: Advanced sensors and cameras enable robots to detect defects and ensure that only products meeting quality standards reach consumers.

Challenges and Solutions

While the benefits of robotics in food manufacturing are clear, there are challenges that need to be addressed:

- High Initial Investment: The cost of implementing robotic systems can be prohibitive for some manufacturers. However, the long-term ROI and the availability of flexible financing options can mitigate this concern.

- Technical Expertise: Operating and maintaining robotic systems require specialized skills. Manufacturers can overcome this by investing in training programs and partnering with robotics providers for support.

- Integration with Existing Systems: Integrating new robotics technology with legacy systems can be complex. Customized solutions and professional integration services can ensure a smooth transition.

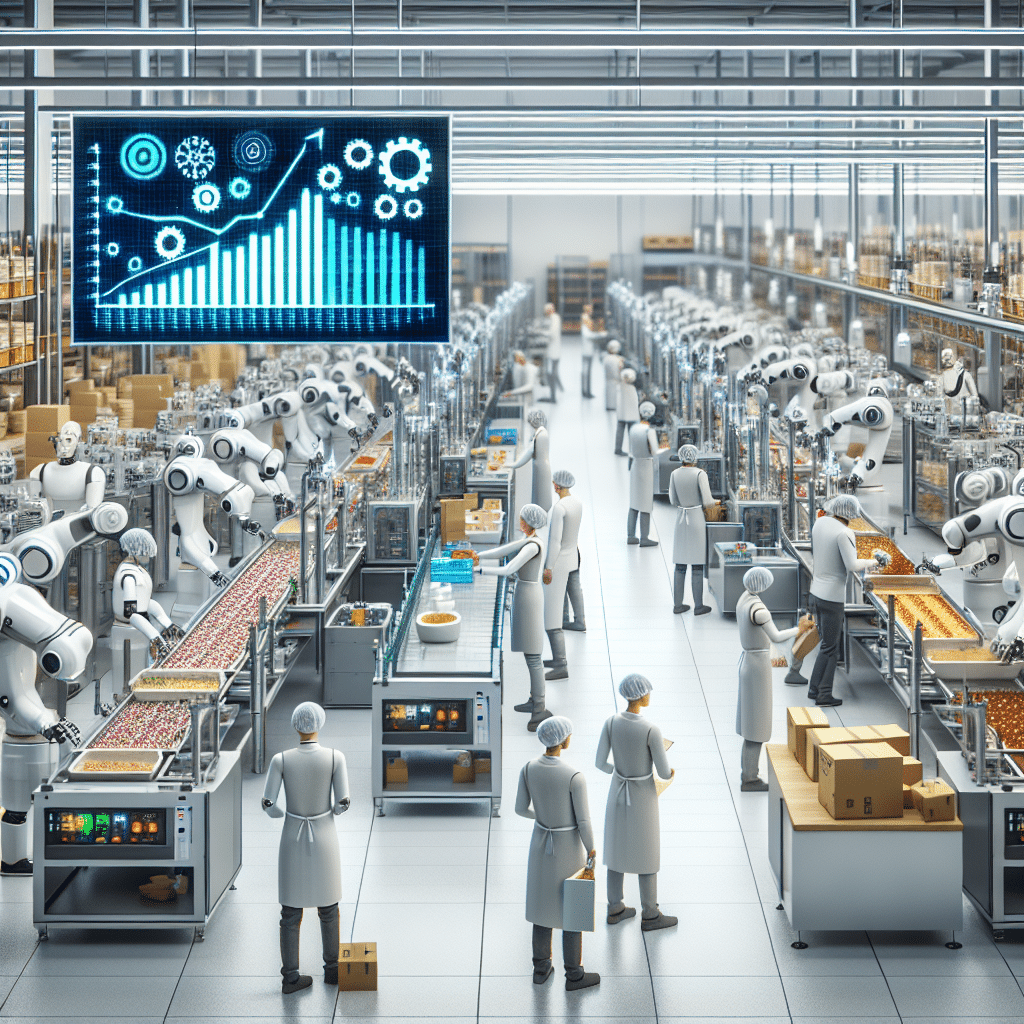

Future Prospects

The future of robotics in food manufacturing looks promising, with ongoing advancements in artificial intelligence (AI) and machine learning enhancing the capabilities of robotic systems. Collaborative robots, or cobots, are also gaining traction as they can work safely alongside human workers, offering flexibility and efficiency.

Conclusion: Embracing the Robotic Era in Food Manufacturing

The popularity of robotics in food manufacturing is a testament to the industry’s commitment to innovation and excellence. By embracing robotics, food manufacturers can achieve higher productivity, improved product quality, and enhanced food safety. As technology continues to evolve, we can expect to see even more sophisticated robotic solutions in the food manufacturing sector.

ETprotein: Your Partner for High-Quality Protein Products

In line with the advancements in food manufacturing, ETprotein offers a range of high-quality protein products that cater to the evolving needs of the industry. Their organic bulk vegan proteins and L-(+)-Ergothioneine (EGT) are ideal for manufacturers looking to enhance their product offerings with nutritious and sustainable ingredients. With a commitment to non-GMO, allergen-free products, and high purity levels, ETprotein is well-positioned to support the food manufacturing industry’s growth.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.