Poultry Industry’s Process of Food Automation.

-

Table of Contents

- Advancements in Poultry Industry Food Automation: A Deep Dive

- The Rise of Automation in Poultry Processing

- Key Areas of Automation in Poultry Processing

- Live Bird Handling: The First Step Towards Automation

- Slaughtering and Evisceration: Precision and Efficiency

- Cutting and Deboning: The Role of Robotics

- Inspection and Quality Control: Ensuring Food Safety

- Packaging and Labeling: The Final Touches

- Statistics Supporting the Shift to Automation

- Challenges and Considerations

- Conclusion: Embracing the Future of Poultry Processing

- ETprotein: Enhancing Poultry Nutrition with High-Quality Protein Products

Advancements in Poultry Industry Food Automation: A Deep Dive

The poultry industry has long been a cornerstone of the global food supply, providing a significant source of protein to populations worldwide. With the ever-increasing demand for poultry products, the industry has turned to automation to enhance efficiency, improve food safety, and reduce labor costs. This article explores the intricate process of food automation within the poultry industry, highlighting the technological advancements that have revolutionized production methods.

The Rise of Automation in Poultry Processing

Automation in the poultry industry is not a new concept; however, the sophistication and extent of its application have grown exponentially in recent years. The integration of advanced robotics, artificial intelligence (AI), and machine learning has enabled processors to achieve higher throughput with greater precision and consistency.

Key Areas of Automation in Poultry Processing

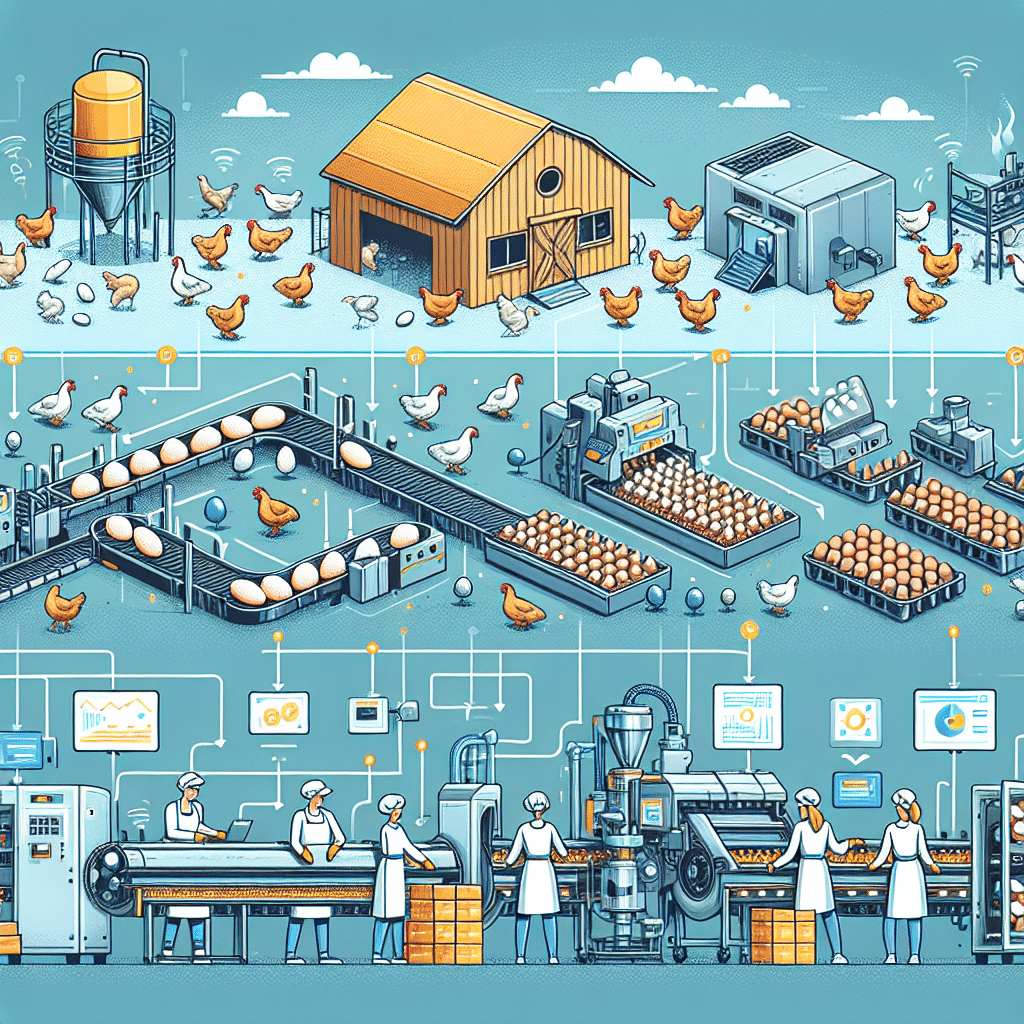

The automation process in poultry production can be segmented into several key areas, each playing a vital role in the supply chain:

- Live Bird Handling

- Slaughtering and Evisceration

- Cutting and Deboning

- Inspection and Quality Control

- Packaging and Labeling

Live Bird Handling: The First Step Towards Automation

The automation journey begins with live bird handling, where automated systems are used to transport birds from farms to processing plants. These systems are designed to minimize stress and injury to the birds, ensuring better meat quality and adherence to animal welfare standards.

Slaughtering and Evisceration: Precision and Efficiency

During slaughtering and evisceration, automation ensures precision cuts and reduces the risk of contamination. Automated plucking machines, evisceration units, and chilling systems streamline the process, leading to a more uniform product and enhanced food safety.

Cutting and Deboning: The Role of Robotics

Robotic systems have been particularly transformative in the cutting and deboning stage. These robots are equipped with vision systems and sensors that allow for precise cuts, maximizing yield and reducing waste. The consistency provided by these systems also helps in maintaining product quality.

Inspection and Quality Control: Ensuring Food Safety

Automated inspection systems utilize advanced imaging technologies to detect defects, contaminants, and inconsistencies in the poultry products. These systems can process vast quantities of products at high speeds, far surpassing the capabilities of manual inspection.

Packaging and Labeling: The Final Touches

Automation extends to the packaging and labeling of poultry products, where machines perform tasks such as weighing, bagging, sealing, and labeling. These systems ensure accurate packaging, which is essential for inventory management, traceability, and compliance with regulatory standards.

Statistics Supporting the Shift to Automation

Recent statistics underscore the impact of automation on the poultry industry:

- According to a report by MarketsandMarkets, the food automation industry is projected to reach $29.4 billion by 2027, growing at a CAGR of 9.5% from 2020 to 2027.

- A study by the Association for Advancing Automation revealed that orders for food and consumer goods robots increased by 56% in the first quarter of 2021 compared to the previous year.

Challenges and Considerations

Despite the benefits, the transition to automation is not without its challenges. High initial investment costs, technical complexities, and the need for skilled personnel to manage and maintain automated systems are significant considerations for poultry processors.

Conclusion: Embracing the Future of Poultry Processing

The poultry industry’s process of food automation represents a significant leap forward in production efficiency, food safety, and product quality. As technology continues to evolve, we can expect even more innovative solutions to emerge, further transforming the industry and setting new standards for poultry production worldwide.

ETprotein: Enhancing Poultry Nutrition with High-Quality Protein Products

In addition to advancements in processing, the quality of poultry feed plays a crucial role in the overall health and productivity of poultry. ETprotein offers a range of high-quality protein products that can significantly enhance poultry nutrition. Their organic and non-GMO protein options, such as rice protein and pea protein, provide essential amino acids necessary for optimal growth and development of poultry. By incorporating ETprotein’s products into poultry feed formulations, producers can ensure a balanced diet for their flocks, leading to healthier birds and superior quality meat products.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.