Processing Of Healthier Snacks Gains From Technology Implications

-

Table of Contents

- Technology Boosts Processing of Healthier Snacks

- The Rise of Healthier Snack Options

- Technological Advancements in Snack Processing

- Implications for the Snack Industry

- Case Studies: Success Stories in Healthier Snack Processing

- Challenges and Considerations

- Conclusion: Embracing Technology for Healthier Snacks

- ETprotein: Enhancing Healthier Snacks with Quality Proteins

Technology Boosts Processing of Healthier Snacks

The snack industry has been undergoing a transformation, driven by the increasing demand for healthier options. Consumers are more health-conscious than ever, seeking snacks that not only satisfy their cravings but also provide nutritional benefits. This shift in consumer behavior has spurred innovation in the snack production sector, with technology playing a pivotal role in developing healthier snacks. In this article, we will explore how technology is revolutionizing the processing of healthier snacks and the implications this has for the industry.

The Rise of Healthier Snack Options

Recent years have seen a surge in the popularity of snacks that are not only tasty but also nutritious. This trend is reflected in market statistics, with the global healthy snack market expected to reach $32.88 billion by 2025, growing at a CAGR of 5.2% from 2020 to 2025. The demand for snacks with reduced fat, lower sugar content, and added functional ingredients is on the rise, pushing manufacturers to innovate and reformulate their products.

Technological Advancements in Snack Processing

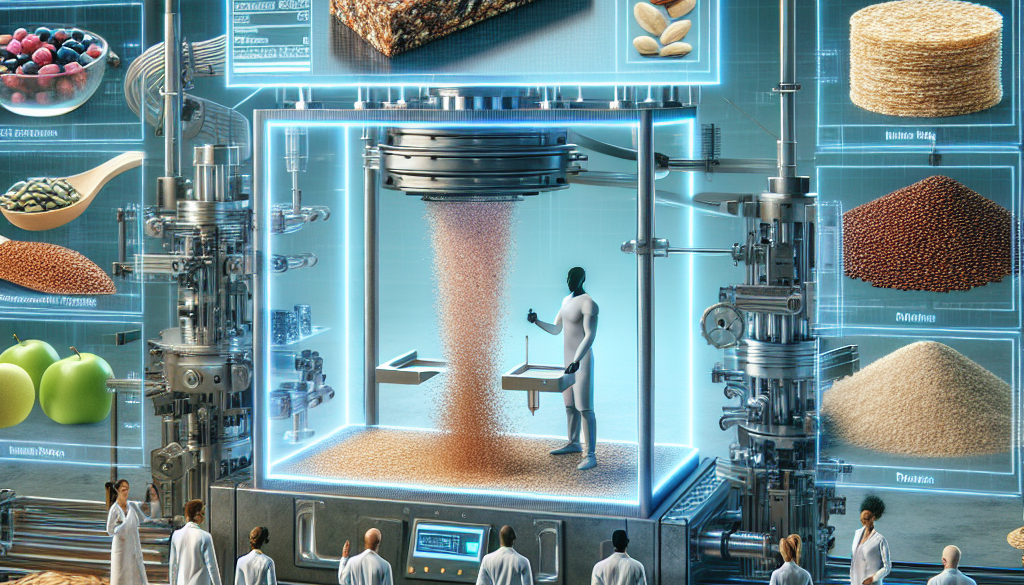

Technology has been a game-changer in the snack industry, enabling manufacturers to create products that meet the evolving demands of health-conscious consumers. Here are some key technological advancements that are shaping the future of healthier snack processing:

- Extrusion Technology: This process allows for the creation of snacks with varied textures and shapes while preserving the nutritional content of the ingredients. It’s particularly useful for producing high-fiber, protein-rich snacks from legumes and whole grains.

- High-Pressure Processing (HPP): HPP is a cold pasteurization technique that uses high pressure to eliminate pathogens in food without the need for high temperatures, thus preserving the nutritional value and extending the shelf life of snacks.

- Vacuum Microwave Drying: This method dries fruits and vegetables at lower temperatures compared to conventional drying, resulting in snacks with better color, flavor, and nutrient retention.

- 3D Food Printing: An emerging technology that allows for the customization of snacks in terms of shape, texture, and nutritional composition, catering to individual dietary needs and preferences.

Implications for the Snack Industry

The integration of technology in snack processing has several implications for the industry:

- Product Innovation: Advanced processing technologies enable the creation of novel snack formats and textures, leading to a broader range of healthier snack options for consumers.

- Improved Nutritional Profiles: Technologies like extrusion and HPP help in retaining the nutritional quality of ingredients, resulting in snacks that are not only healthier but also more appealing to health-conscious consumers.

- Sustainability: Many of these technologies are energy-efficient and reduce waste, contributing to more sustainable production practices in the snack industry.

- Customization: With technologies like 3D food printing, manufacturers can offer personalized snacks tailored to individual nutritional needs, opening up new market segments.

Case Studies: Success Stories in Healthier Snack Processing

Several companies have successfully leveraged technology to produce healthier snacks. For instance, a snack manufacturer used extrusion technology to create a high-protein, low-carb chip that has become a hit among fitness enthusiasts. Another company utilized vacuum microwave drying to produce fruit snacks that retain nearly all of the vitamins and antioxidants of fresh fruit.

Challenges and Considerations

While technology offers numerous benefits, there are challenges and considerations that manufacturers must address:

- Cost: Investing in new technologies can be expensive, and smaller companies may struggle to afford the initial outlay.

- Consumer Acceptance: Some consumers may be skeptical of snacks produced using unfamiliar technologies, requiring education and transparency from manufacturers.

- Regulatory Compliance: As new technologies emerge, regulatory bodies may need time to establish guidelines, which can be a hurdle for manufacturers.

Conclusion: Embracing Technology for Healthier Snacks

The snack industry is at a crossroads, with technology offering a path to healthier, more sustainable, and innovative products. By embracing these technological advancements, manufacturers can meet the growing demand for snacks that are both delicious and nutritious. As the industry continues to evolve, we can expect to see even more exciting developments in the processing of healthier snacks.

ETprotein: Enhancing Healthier Snacks with Quality Proteins

For manufacturers looking to enhance their healthier snack offerings, ETprotein’s range of protein products can be a valuable addition. Their organic bulk vegan proteins, including rice, pea, and seed-based proteins, are non-GMO, allergen-free, and characterized by a neutral taste, making them an excellent ingredient for a variety of snack applications. With L-(+)-Ergothioneine purity over 98%, ETprotein’s products meet the highest quality standards, ensuring that your snacks not only taste great but also contribute to a healthier diet.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.