Quality Changes Of Rice Made From Rice Treated With Different Pressures During Refrigeration

Exploring the impact of ultra-high pressure treatments on refrigerated rice quality, comparing 200, 400, and 600 MPa effects on sensory attributes.

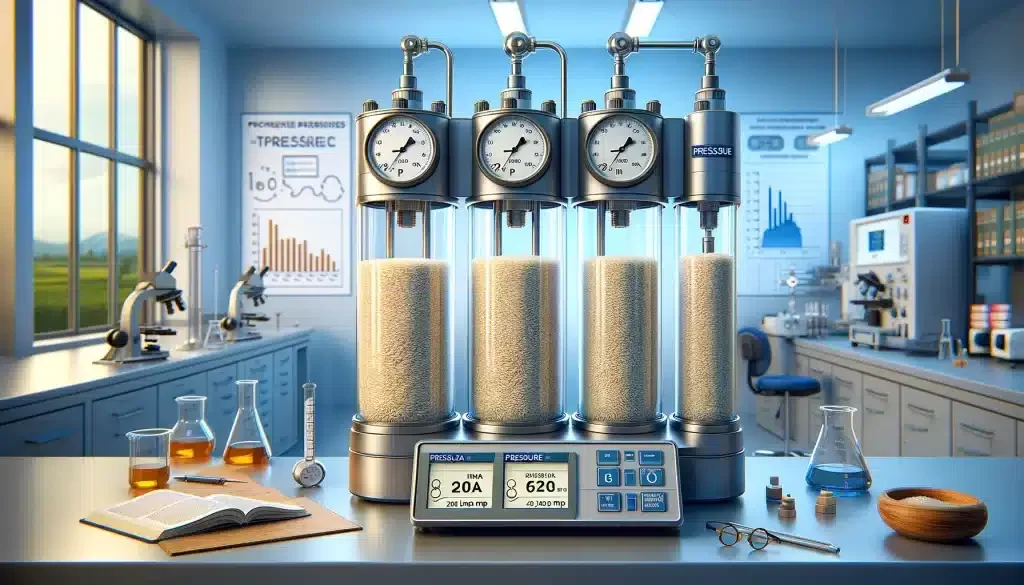

The changes in the quality of rice produced from rice treated with different pressures under refrigeration conditions were studied. Rice was soaked for 40 minutes at a temperature of 40¡ãC and a rice-water ratio (m/m) of 1:2, and treated at 200, 400, and 600 MPa for 10 minutes at 15¡ãC. Rice that was not treated with ultrahigh pressure after soaking As a control test group, rice was then steamed for 15 min, sealed with plastic wrap and stored at 4¡ãC for 7 d. Rice quality-related indicators were measured every day and compared with the sensory evaluation results. The results show that the hardness of ultra-high pressure rice rises slowly; the stickiness, iodine blue value, and pH all drop quickly; the transmittance and whiteness (W) all rise quickly. The moisture content of rice at 400 and 600 MPa changes significantly. During storage, 200 MPa rice had the highest W and iodine blue values, the lowest pH value, and low sensory score. The hardness, pH value and W of 400 MPa rice were all lower, and the sensory score was close to the control. The 600 MPa rice has higher hardness and lower W. The iodine blue value decreases and the light transmittance increases the fastest. The sensory score is the lowest and the decrease rate is the fastest. Generally speaking, the effects of 200, 400, and 600 MPa treatment on rice refrigeration quality are more harmful than beneficial.

Methodology and Experimental Design

In an innovative exploration of food preservation techniques, a study meticulously evaluated the alterations in rice quality resulting from different ultra-high pressure treatments under refrigeration conditions. This investigation stands at the forefront of advancing our understanding of food science, particularly in enhancing the longevity and maintaining the quality of staple foods such as rice under refrigeration. The methodology involved soaking rice for 40 minutes at a temperature of 40°C with a rice-water ratio of 1:2, followed by subjecting it to pressures of 200, 400, and 600 MPa for 10 minutes at 15°C. A control group was established by not subjecting rice to ultra-high pressure after soaking. Subsequently, all rice samples were steamed for 15 minutes, sealed with plastic wrap, and stored at 4°C for 7 days. The study’s thoroughness extended to daily measurements of rice quality-related indicators, which were then juxtaposed with sensory evaluation results to gauge the treatments’ efficacy.

Findings: Effects of Pressure on Rice Quality

The findings reveal a nuanced understanding of how ultra-high pressure impacts rice quality over refrigeration storage. Specifically, rice treated at ultra-high pressure exhibited a gradual increase in hardness, while parameters such as stickiness, iodine blue value, and pH experienced a rapid decline. Conversely, transmittance and whiteness (W) indicators saw a swift rise. Notably, rice subjected to 400 and 600 MPa treatments demonstrated significant moisture content fluctuations, underscoring the profound impact of pressure treatment on rice’s physical properties.

Comparative Analysis of Different Pressure Treatments

The comparative analysis of rice treated at 200, 400, and 600 MPa yielded insightful distinctions. Rice treated at 200 MPa showcased the highest W and iodine blue values alongside the lowest pH value, albeit with a lower sensory score, suggesting a mixed impact on rice quality. The 400 MPa treatment resulted in lower hardness, pH value, and W, with sensory scores closely aligning with the control group, indicating a potentially optimal pressure setting for maintaining quality. However, rice subjected to 600 MPa displayed increased hardness and decreased W, with the fastest decrease in iodine blue value and increase in light transmittance, culminating in the lowest and fastest declining sensory scores. These observations suggest that while ultra-high pressure treatments can influence rice quality, the effects largely veer towards the negative, especially at higher pressure levels.

Conclusion and Implications for Food Preservation

In summary, this comprehensive study sheds light on the intricate dynamics between ultra-high pressure treatments and rice quality under refrigeration, highlighting the critical balance needed to harness such technologies effectively. Although the treatments at 200 and 400 MPa presented some benefits, the overarching findings point towards a detrimental effect on rice quality, with the 600 MPa treatment being the most adverse. These insights pave the way for further research into optimizing pressure treatments to extend the shelf life of rice and possibly other grains without compromising their quality, a quest that holds promising implications for food science and preservation strategies.

For futher details of this article and research, feel free to contact our team for assistance.

Original research was done by Duan Xiaoming

About ETprotein:

ETprotein, a reputable plant protein vegan protein Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan protein and plant proteins. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, oat protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, various of plant peptides etc. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to get a free sample of their protein products, please contact them and email sales(at)ETprotein.com today.