Reducing Acrylamide in Food Processing

-

Table of Contents

- Acrylamide Reduction Strategies in Food Processing

- Understanding Acrylamide Formation

- Regulatory Guidelines and Health Implications

- Strategies for Reducing Acrylamide

- Raw Material Selection and Storage

- Recipe and Process Modification

- Pre-treatment Techniques

- Advanced Technologies

- Case Studies and Examples

- Statistics and Research

- Conclusion

- ETprotein’s Commitment to Safe and Healthy Food Ingredients

Acrylamide Reduction Strategies in Food Processing

Acrylamide, a chemical compound that can form in some foods during high-temperature cooking processes, has raised health concerns due to its potential carcinogenic properties. As a result, the food industry has been actively seeking methods to reduce acrylamide levels in processed foods. This article explores the various strategies and techniques that can be employed to minimize acrylamide formation during food processing, ensuring safer consumption without compromising on taste and quality.

Understanding Acrylamide Formation

Acrylamide is formed when asparagine, an amino acid, reacts with reducing sugars such as glucose and fructose during high-temperature cooking, typically above 120°C (248°F). This reaction is part of the Maillard browning process, which gives many foods their characteristic flavor and color. Foods that are prone to acrylamide formation include potato products, coffee, bread, and certain cereal products.

Regulatory Guidelines and Health Implications

Regulatory bodies worldwide, including the European Food Safety Authority (EFSA) and the U.S. Food and Drug Administration (FDA), have issued guidelines to mitigate acrylamide exposure. Long-term animal studies have shown that high levels of acrylamide can cause cancer in laboratory animals, and while studies in humans are inconclusive, the potential risk has led to a call for reduced levels in food products.

Strategies for Reducing Acrylamide

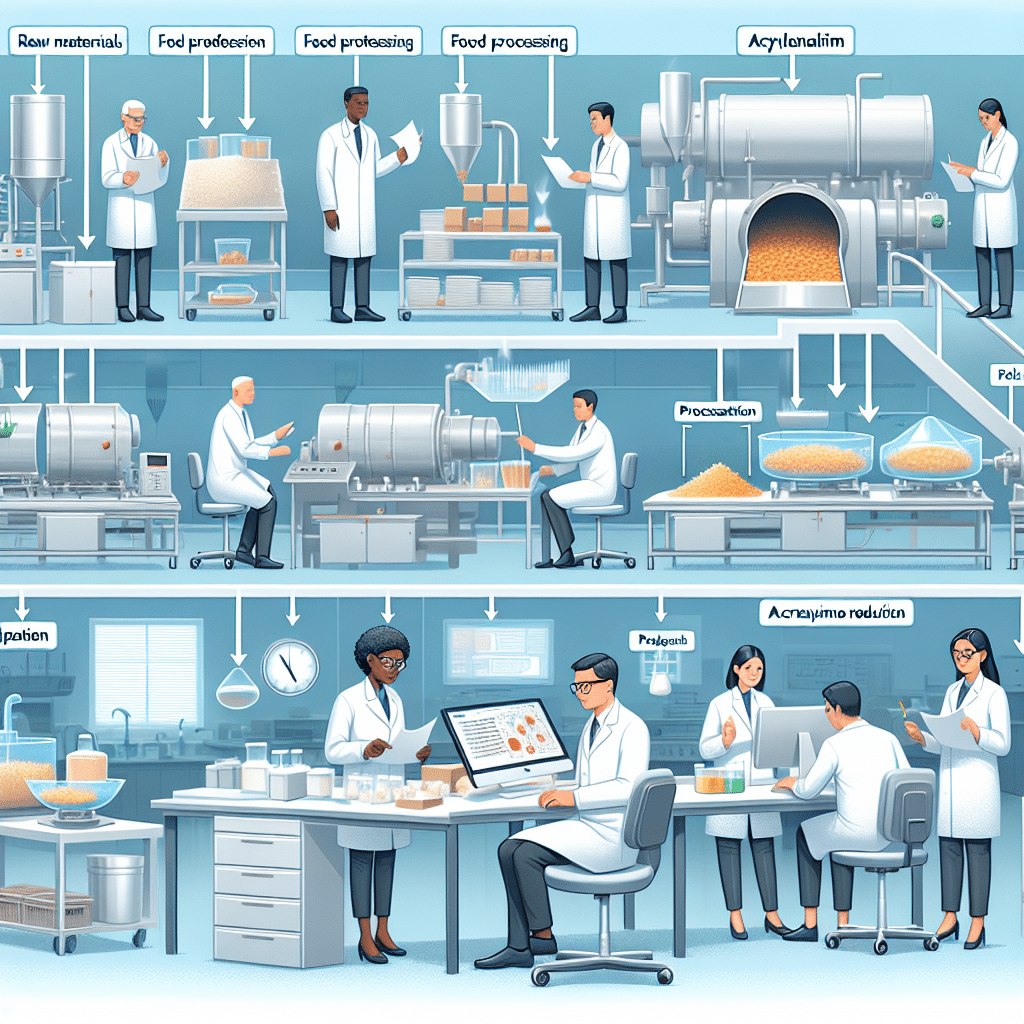

Food manufacturers can adopt several strategies to reduce acrylamide formation during processing. These strategies can be applied at different stages of production, from raw material selection to final cooking methods.

Raw Material Selection and Storage

- Choose low-sugar and low-asparagine varieties of raw materials.

- Store potatoes at temperatures above 8°C (46°F) to prevent sugar formation.

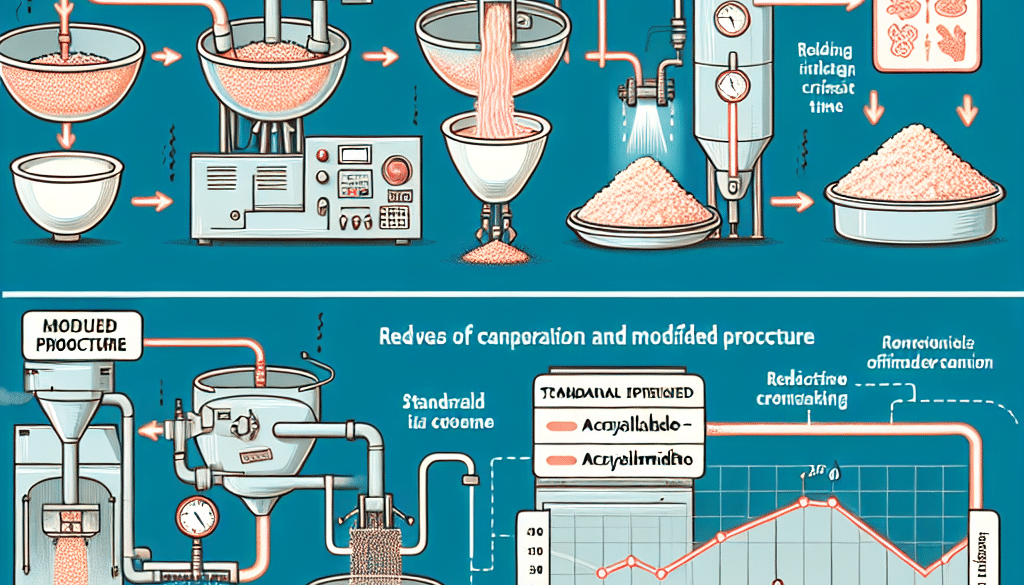

Recipe and Process Modification

- Adjust recipes to lower the amounts of reducing sugars and asparagine.

- Alter cooking times and temperatures to minimize browning.

Pre-treatment Techniques

- Blanching: Pre-cooking at lower temperatures can reduce asparagine levels.

- Soaking: Soaking raw materials in water or calcium solutions can leach out sugars and asparagine.

Advanced Technologies

- Use of enzymes: Asparaginase can convert asparagine into aspartic acid, which does not form acrylamide.

- Vacuum frying: Cooking at lower pressures reduces acrylamide formation.

Case Studies and Examples

Several food manufacturers have successfully implemented acrylamide reduction strategies:

- A leading potato chip company reduced acrylamide by 50% through a combination of selecting the right potato varieties and optimizing cooking temperatures.

- A coffee producer managed to lower acrylamide content by adjusting the roasting profile without affecting flavor.

Statistics and Research

Research indicates that acrylamide levels in food can be reduced significantly with the right approaches. For instance, studies have shown that blanching potatoes before frying can reduce acrylamide formation by up to 90%. Additionally, the use of asparaginase has been demonstrated to decrease acrylamide content by up to 80% in certain products.

Conclusion

Reducing acrylamide in food processing is a multifaceted challenge that requires a combination of careful raw material selection, recipe adjustments, and innovative cooking techniques. By implementing these strategies, food manufacturers can significantly lower the levels of acrylamide in their products, ensuring consumer safety while maintaining taste and quality. The key takeaways for the industry are to stay informed about the latest research, comply with regulatory guidelines, and continuously seek improvements in processing methods.

ETprotein’s Commitment to Safe and Healthy Food Ingredients

ETprotein is dedicated to providing high-quality protein products that align with the industry’s efforts to produce healthier food options. Their range of organic bulk vegan proteins, including rice, pea, and various seed proteins, are produced with safety and health in mind. These non-GMO, allergen-free protein sources are an excellent choice for food manufacturers looking to enhance the nutritional profile of their products while adhering to safety standards.

For companies seeking to reduce acrylamide in their food processing, ETprotein’s protein products offer a safe and nutritious alternative ingredient. Their commitment to quality ensures that their proteins not only contribute to a balanced diet but also support the industry’s goal of minimizing potential health risks associated with food processing.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.