Refining and product analysis of rice protein peptide liquid

Explore the innovative refinement and analysis of rice protein peptides for enhanced food and pharmaceutical applications, featuring optimal purification processes.

Keywords: rice feed protein, rice peptide, ultrafine grinding, water washing, enzymatic hydrolysis, decolorization, desalination

Introduction

Rice feed protein, after hydrolysis with alkaline, neutral, and acid proteases, results in a mixture of low-molecular-weight peptides and free amino acids. Despite the high content of proteins and peptides, this mixture contains various impurities, salts, and other color components, necessitating purification processes such as decolorization and desalting to meet the standards for pharmaceutical or food additive applications.

Materials and Methods

Raw Materials and Main Reagents

- Rice protein peptide solution

- Powdered activated carbon

- Cation exchange resin 732

- Anion exchange resin 717

Equipment

- Glass chromatography column (1.6cm×60cm)

- DDS-11A conductivity meter

- Super thermostatic water bath

- UV-2000 spectrophotometer

- LXJ-II type centrifuge sedimentation machine

Experimental Procedures

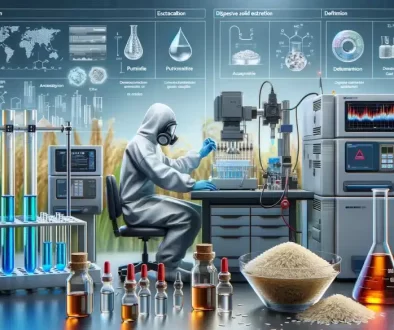

Protein content was measured using the micro-Kjeldahl method, ash content through muffle furnace ashing, and desalting rate by calculating the difference in ash content before and after desalting. Decolorization was achieved using powdered activated carbon, with the efficiency evaluated by measuring absorbance changes at 420nm. Peptide loss and recovery rates were determined through precipitation and protein content analysis in filtrates.

Results and Discussion

Effects of Activated Carbon on Decolorization

The study explores the impact of varying concentrations of activated carbon on decolorization efficiency and peptide loss, finding an optimal concentration for balancing color removal and minimizing peptide loss. Temperature, time, and pH were also optimized based on their effects on decolorization outcomes.

Desalting Process Optimization

Ion exchange resins were used for desalting, with flow rates adjusted to optimize peptide recovery while ensuring satisfactory desalting efficiency. The optimal conditions were identified, taking into account the trade-off between peptide recovery and desalting performance.

Solubility and Peptide Yield Analysis

The solubility of rice peptide powders significantly exceeded that of the raw materials, highlighting the effectiveness of enzymatic hydrolysis and processing techniques in enhancing protein solubility. The yield and purity of rice peptides were calculated, demonstrating the efficiency of the production process.

Amino Acid Analysis

The amino acid composition of rice feed protein hydrolysate was analyzed, revealing a comprehensive profile of essential and non-essential amino acids. The study discusses the implications of these findings for the nutritional value and potential applications of rice protein peptides.

Molecular Weight Distribution

Gel chromatography was employed to assess the molecular weight distribution of the peptides, indicating a wide range of peptide sizes and highlighting the continuous nature of the enzymatic hydrolysis process.

Conclusion

This research provides insights into the refinement processes for rice protein peptide solutions, including decolorization and desalting, and analyzes the product’s composition, solubility, amino acid profile, and molecular weight distribution. The findings contribute to the understanding of rice peptide production and its potential applications in food and pharmaceutical industries.

For more further detailed information of this research, feel free to contact our team for asssistance.

The original research is done by HE Qiangfei,GUO Guanxin,YU Qiusheng(School of Food Science, Jiangnan University, Wuxi,214122, China) The ariticle ID is: doi: 10.7666/d.y1397665